PROCEDURE

NOTE: Refacing the rotor is not required each time the brake pads are replaced, only when the need is foreseen.

Any servicing of the rotor requires extreme care to maintain the rotor within service tolerances to ensure proper brake action.

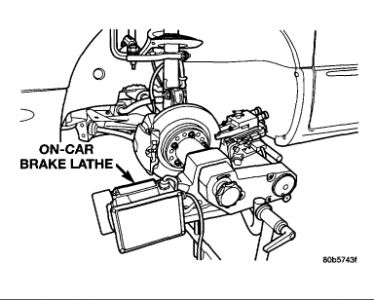

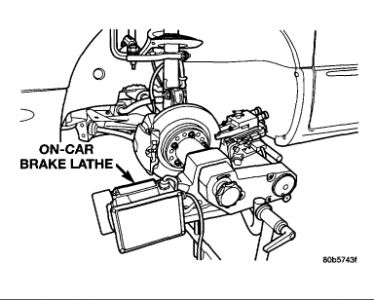

On-Car Brake Lathe

If the rotor surface is deeply scored or warped, or there is a complaint of brake roughness or brake pedal pulsation, the rotor should be refaced using a hub-mounted on-car brake lathe, or replaced.

The use of a hub-mounted on-car brake lathe is highly recommended to eliminate the possibility of excessive runout. It trues the brake rotor to the vehicle's hub and bearing.

Minimum Brake Rotor Thickness Markings (Typical)

NOTE: All rotors have markings for minimum allowable thickness cast on an un-machined surface of the rotor.

Minimum allowable thickness is the minimum thickness which the brake rotor machined surface may be cut to.

CAUTION: Do not machine the rotor if it will cause the rotor to fall below minimum thickness.

Before installation, verify the brake rotor face and the hub adapters are free of any chips, rust, or contamination.

When mounting and using the brake lathe, strict attention to the brake lathe manufacturer's operating instructions is required.

Machine both sides of the brake rotor at the same time. Cutting both sides at the same time minimizes the possibility of a tapered or uneven cut.

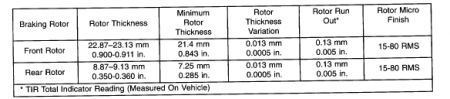

SPECIFICATIONS AND LIMITS

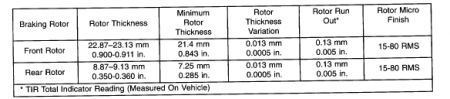

When refacing a rotor, the required TIR (Total Indicator Reading) and thickness variation limits MUST BE MAINTAINED. Extreme care in the operation of rotor turning equipment is required.

BRAKE ROTOR REFINISHING LIMITS

Sunday, January 24th, 2010 AT 2:24 AM