I think this is what you are looking for good luck

SHORT STUB SHAFT OIL SEAL

NOTE:The following procedure can be used to change oil seal without removing transaxle from vehicle or having to reset ring gear backlash and differential bearing rotating torque. If any components except oil seals are replaced, the following procedure cannot be used. Short stub shaft is right stub shaft when viewed from rear of transaxle.

Removal

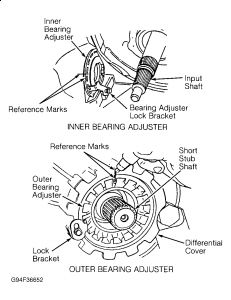

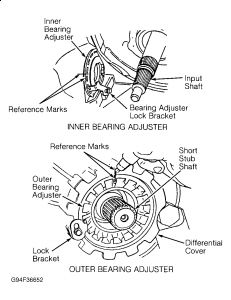

Raise and support vehicle. Remove passenger's side axle shaft. Place reference marks on differential cover and outer bearing adjuster located near short stub shaft on right side of transaxle for reassembly reference. See Fig.

Remove bolt and lock bracket from outer bearing adjuster. See Fig. Using Socket (6503), rotate outer bearing adjuster slightly counterclockwise.

Using torque wrench, measure amount of torque required to rotate outer bearing adjuster clockwise until reference marks are realigned. Note torque reading for reassembly reference.

Using socket, remove outer bearing adjuster from differential cover. Press oil seal from outer bearing adjuster.

Installation

Press NEW oil seal into outer bearing adjuster. Check for corrosion on short stub shaft. If corrosion is present, wrap short stub shaft with wax paper before installing seal protector.

Install Seal Protector (6591) on short stub shaft. Lubricate seal protector and lip of oil seal with gear oil. Install NEW "O" ring on outer bearing adjuster. Lubricate threads on outer bearing adjuster with gear oil.

Screw outer bearing adjuster into transaxle case until torque reading is 120 INCH lbs. (13.6 N.m) less than torque value obtained in step 4 during removal. Rotate differential assembly several times in both directions to seat bearings.

Tighten outer bearing adjuster until reference marks are aligned. Install lock bracket on outer bearing adjuster. Install and tighten lock bracket bolt to specification.

Remove seal protector and wax paper (if used) from short stub shaft.

Install NEW "C" clip and "O" ring on outer end of short stub shaft. Install axle shaft. Fill differential with Mopar 75W-90 petroleum based hypoid gear lubricant. DO NOT use synthetic gear oil.

During certain conditions, pressure can build up in differential case, causing gear lubricant to blow out of differential vent tube. Manufacturer has introduced an auxiliary vent tube to improve this condition. Vent Tube (05011589AA) connects to new design differential filler plug, located on differential side cover. Vent tube is positioned between ribs on differential cover.

Monday, April 13th, 2020 AT 7:00 PM

(Merged)