Hello -

On the fuel gauge. . .I did find a TSB that you could check on a bad wire connector under the seat.

If that isn't it then it is probably the sender on the fuel pump. If it were me. . ..if I went to the trouble to drop the tank. . ..I would change the entire fuel pump.

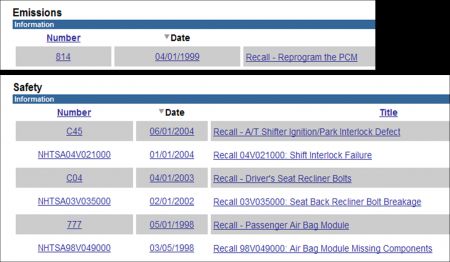

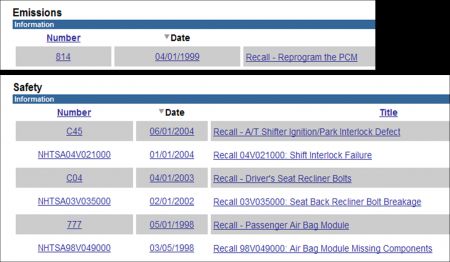

Last, you may have some recalls on your vehicle. The dealer may fix these for free. Please contact the dealer service department, give them the VIN number of your car and have them check on these to see if they apply to you.

Fuel System - MIL ON DTC Set/Driveability Concerns

Notes

NUMBER: 08-35-99

GROUP: Electrical

DATE: Oct. 8, 1999

SUBJECT:

MIL Illumination, Leak Detection Pump DTC and/or Fuel Gauge Inaccurate

OVERVIEW:

This bulletin involves replacing the inline fuel tank to left body harness connector with a sealed connector.

MODELS:

1998 - 1999 (LH) Concorde/Intrepid/LHS/3OOM

SYMPTOM/CONDITION:

MIL illumination with Leak Detection Pump (LDP) Diagnostic Trouble Code (DTC), fuel gauge reading inaccurate, fuel pump not working, and/or engine run-on.

DIAGNOSIS:

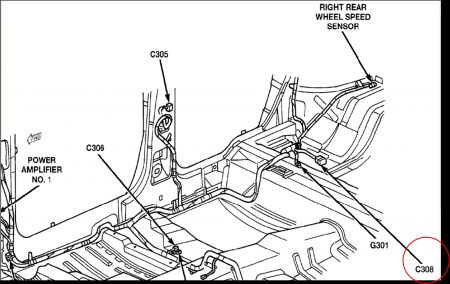

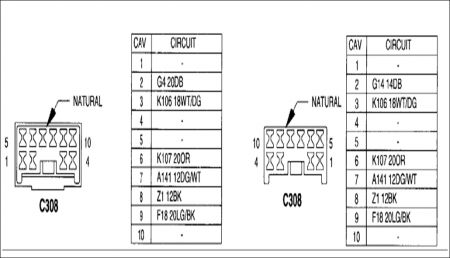

Using the Mopar Diagnostic System (MDS2) and/or the Diagnostic Scan Tool (DRB III) with the appropriate Diagnostic Procedures Manual, verify all engine/transmission systems are functioning as designed. If non-LDP related DTC's are present, record them on the repair order and repair as necessary before proceeding further with this bulletin. If Leak Detection Pump DTC's are present, and/or owner describes an inaccurate fuel gauge or engine run-on, inspect the C308 wire connector located under the rear seat cushion for the presence of moisture and/or corrosion. If moisture/corrosion exist, perform the Repair Procedure.

PARTS REQUIRED:

1 05013984AA Insulator/Terminal Repair Kit

1 05013988AA Insulator/Terminal Repair Kit

12 04778570 Heat Shrink Tubing

POLICY: Reimbursable within the provisions of the warranty.

TIME ALLOWANCE:

Labor Operation No: 08-90-73-90 0.8 Hrs.

FAILURE CODE: P8 - New Part

Repair Procedure

Notes

1. Disconnect and isolate the negative battery remote cable.

2. Locate and remove the existing C308 connector by cutting the five wires (LDP equipped)/three wires (non-LDP equipped) on each side of the connector. Stagger cut all wires on the harness sides at 1/2 inch intervals.

3. Remove 1 inch of insulation from each wire on the harness sides.

4. Stagger cut the matching wires on the repair connector assemblies in the opposite order of the harness stagger.

5. Remove 1 inch of insulation from each wire on the repair connector.

6. Place a piece of heat shrink tubing over one side of the wire.

7. Spread the strands of the wire apart on each part of the exposed wires.

8. Push the two ends of wire together until the strands of wire are close to the insulation.

9. Twist the wires together.

10. Solder the connection together using rosin core solder. Do not use acid core solder.

11. Center the heat shrink tubing over the joint and heat using a heat gun. Heat the joint until the tubing is tightly sealed and sealant comes out of both ends of the tubing.

12. Repeat steps 6 through 11 for each wire.

NOTE :ALL CAVITIES IN THE SIX-WAY INLINE CONNECTORS, ON BOTH SIDES OF THE CONNECTION MUST BE FILLED WITH TERMINATED WIRES. ANY WIRES THAT ARE NOT USED MUST HAVE THE NON- TERMINATED END SEALED WITH HEAT SHRINK.

13. Re-tape the wire harness and connect the connector halves.

14. Connect the negative battery remote terminal.

Saturday, December 6th, 2008 AT 8:19 PM