Most likley cause is the enginge mounts, or engine/transmission isnt centered in the bay correctly, any accident damage? Is the inboard joint spring loaded? Spring could be weak on it too!

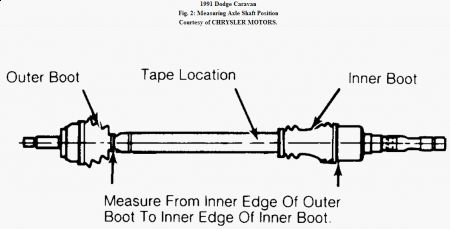

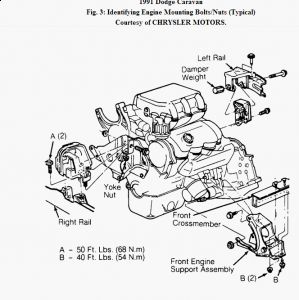

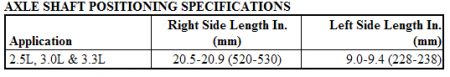

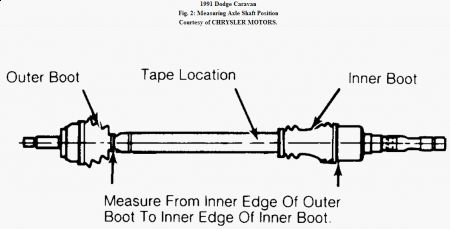

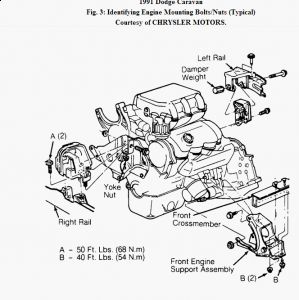

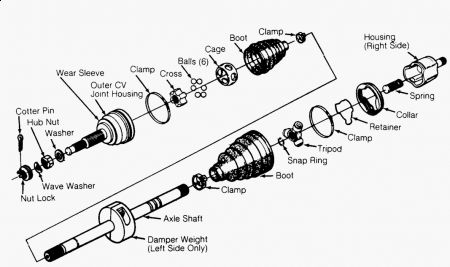

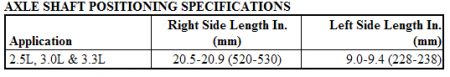

AXLE SHAFT POSITIONING ADJUSTMENTS 1. Engine mount bolt holes are slotted for side-to-side positioning of engine. With vehicle completely assembled, ensure front wheels are in straight ahead position. Vehicle should be on platform hoist or alignment rack. 2. Using a tape measure, measure distance from inner edge of outer boot to inner edge of inner boot on both axle shafts. See Fig. 2 . This measurement must be taken at bottom of axle shaft only. Fig. 2: Measuring Axle Shaft Position Courtesy of CHRYSLER MOTORS. 3. If both axle shafts are within specifications, no further service is necessary. If either left or right axle shaft is not within specification, support engine/transaxle assembly using a floor jack. See AXLE SHAFT POSITIONING SPECIFICATIONS table. 4. Loosen right engine mount fasteners, front engine mount bracket and front crossmember fasteners. Pry engine right or left as required to obtain the correct axle shaft length. Refer to the below AXLE SHAFT POSITIONING SPECIFICATIONS table. 5. Tighten mounting bolts/nuts to specifications. See Fig. 3 . Recheck axle shaft length. Install damper weight (if equipped), and tighten to specification. See TORQUE SPECIFICATIONS table. Fig. 3: Identifying Engine Mounting Bolts/Nuts (Typical) Courtesy of CHRYSLER MOTORS.

NOTE: Check axle shaft positioning if engine/transaxle is loosened or moved or if front structural damage has occurred. Incorrect axle shaft positioning may result in premature failure of components.

SPONSORED LINKS

Saturday, March 28th, 2009 AT 8:09 AM