Saturday, December 28th, 2024 AT 8:42 AM

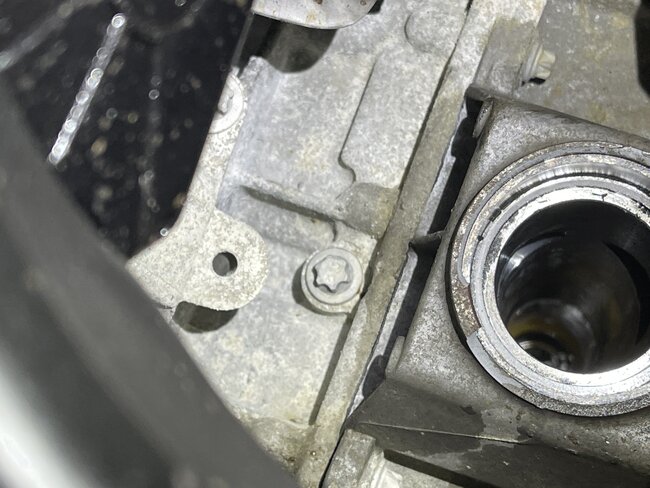

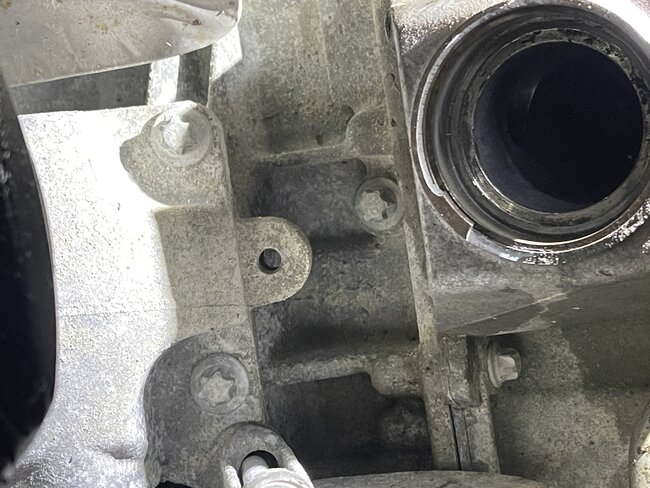

Was removing the driver side axle on this car. The intermediate shaft was stuck and rusted to the axle. While hammering the axle out the c clamp that holds the intermediate to the oil pan came out and I realized the edge mating surface broke half the edge. If installed like it is will cause any issues if I don't put back the c clip? The intermediate shaft is very long and goes in through the oil pan to the transfer case. Reason I am asking is because this is going to be a pain to remove the oil pan.