Hi,

I'm sorry, but I can't enlarge the pic enough to read it.

As far as the codes you presently have, they are related to the crankshaft position sensor. I suspect, since you replaced the sensor, either the new one is bad, there is a connection issue, or one of the wires has rubbed through on the truck and is shorting.

You have a scanner, so here are the diagnostics for the P0339. The P0300 is resulting from the 339.

_____________________________________

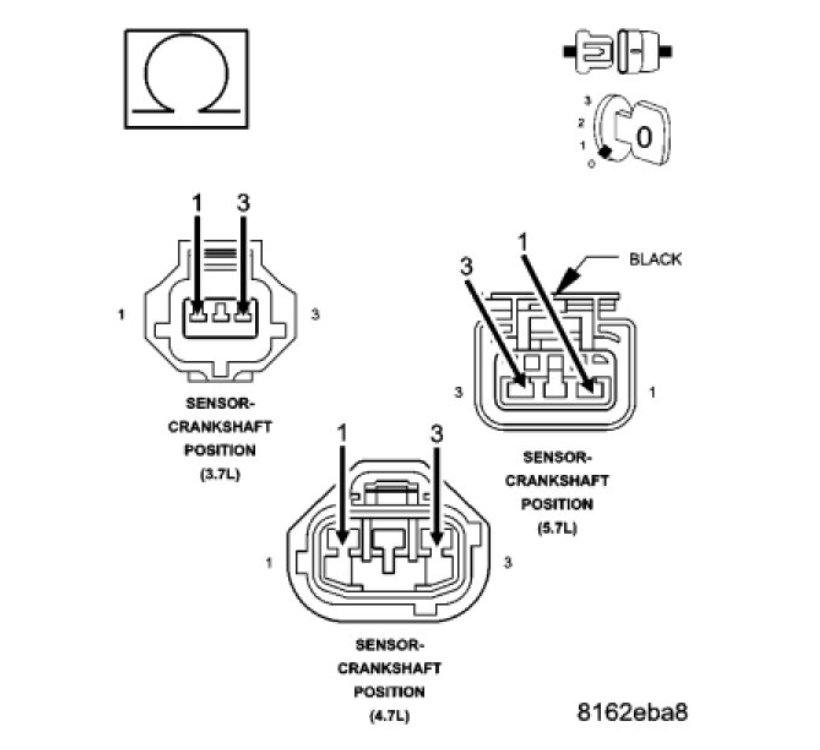

The attached pictures correlate with the directions. The directions are checking for wiring issues. The pins in the connectors are indicated in the pictures.

2007 Dodge or Ram Truck RAM 1500 Truck 2WD V8-4.7L VIN N

Vehicle ALL Diagnostic Trouble Codes ( DTC ) Testing and Inspection P Code Charts P0339 GAS

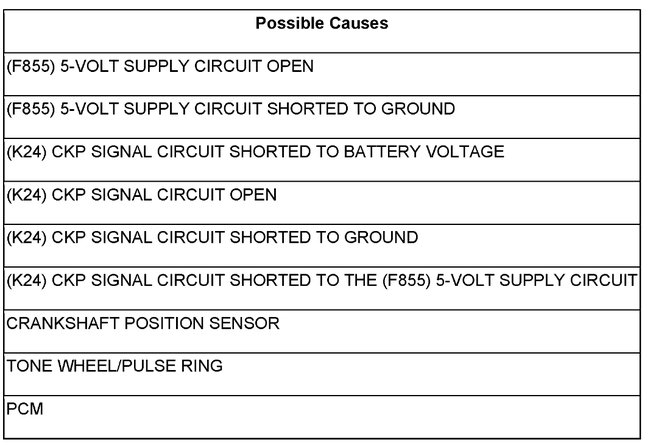

P0339-CRANKSHAFT POSITION SENSOR INTERMITTENT

pic 1

For complete wiring diagrams refer to Diagrams/Electrical.

- When Monitored:

While cranking the engine and with the engine running.

- Set Condition:

When the CKP Sensor failure counter reaches 20. One Trip Fault. Three good trips to turn off the MIL.

Pic 2

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding.

Diagnostic Test

1. ACTIVE DTC

Ignition on, engine not running.

With a scan tool, select View DTCs.

Is the DTC Active at this time?

Yes

- Go To 2

No

- Refer to the INTERMITTENT CONDITION Diagnostic Procedure. See: Computers and Control Systems > Component Tests and General Diagnostics > Intermittent Condition

2. CHECKING CRANKSHAFT POSITION SENSOR SIGNAL WITH A LAB SCOPE

Turn the ignition off.

With a lab scope probe and the Miller special tool #6801, backprobe the (K24) CKP Signal circuit in the Sensor harness connector.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands near the pulleys, belts, or fan. Do not wear loose clothing. Failure to follow these instructions can result in personal injury or death.

Ignition on, engine not running.

Observe the lab scope screen.

Start the engine.

Observe the lab scope screen.

Are there any irregular or missing signals?

Yes

- Go To 3

No

- Go To 8

3. WIRE HARNESS INSPECTION

Turn the ignition off.

Visually inspect the related wire harness including the ground circuit. Look for any chafed, pierced, pinched, or partially broken wires.

Visually inspect the related wire harness connectors. Look for broken, bent, pushed out, or corroded terminals.

Make sure the Crankshaft Position Sensor and the Camshaft Position Sensor are properly installed and the mounting bolt(s) are torqued to the proper specification.

Refer to any TSBs that may apply.

Were any of the above conditions present?

Yes

- Repair as necessary.

- Perform POWERTRAIN VERIFICATION TEST. See: A L L Diagnostic Trouble Codes ( DTC ) > Verification Tests > Powertrain Verification Test

No

- Go To 4

4. (F855) 5-VOLT SUPPLY CIRCUIT OPEN OR SHORTED TO GROUND

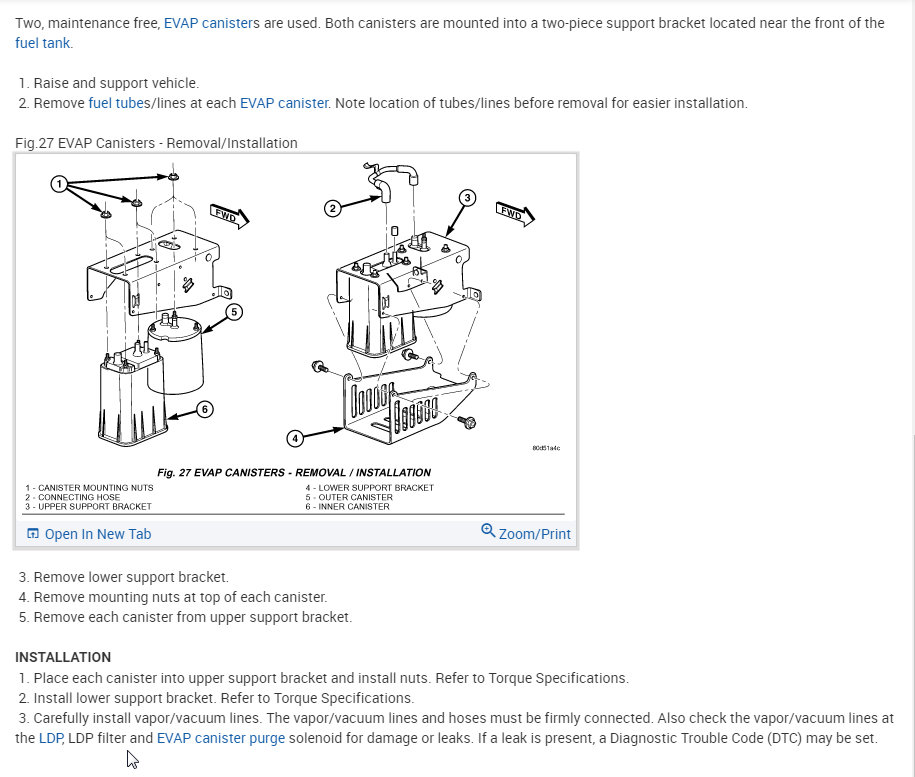

pic 3

Disconnect the CKP Sensor connector.

Ignition on, engine not running.

Measure the voltage on the (F855) 5-volt Supply circuit in the Sensor harness connector.

Is the voltage between 4.5 and 5.2 volts?

Yes

- Go To 5

No

- Repair the open or short to ground in the (F855) 5-volt Supply circuit. Use Miller special tool #8815 when checking for an open circuit to prevent PCM harness connector terminal damage.

- Perform POWERTRAIN VERIFICATION TEST. See: A L L Diagnostic Trouble Codes ( DTC ) > Verification Tests > Powertrain Verification Test

5. TONE WHEEL/FLEX PLATE INSPECTION

Turn the ignition off.

Carefully disconnect the Negative Battery (Ground) cable.

Remove the Crankshaft Position Sensor.

Inspect the Tone Wheel/Flex Plate slots for damage, foreign material, or excessive movement.

Were any problems found?

Yes

- Repair or replace the Tone Wheel/Flex Plate as necessary.

- Perform POWERTRAIN VERIFICATION TEST. See: A L L Diagnostic Trouble Codes ( DTC ) > Verification Tests > Powertrain Verification Test

No

- Go To 6

6. CHECKING CAMSHAFT POSITION SENSOR SIGNAL WITH A LAB SCOPE

Install the CKP Sensor and connect the battery cable.

NOTE: An intermittent condition in the Cam Position Sensor can cause the P0339 to set.

With the a lab scope probe and the Miller special tool #6801, backprobe the (K44) CMP Signal circuit in the Sensor harness connector.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands near the pulleys, belts, or fan. Do not wear loose clothing. Failure to follow these instructions can result in personal injury or death.

Ignition on, engine not running.

Wiggle the related wire harness and lightly tap on the Cam Position Sensor.

Observe the lab scope screen.

Start the engine.

Observe the lab scope screen.

Are there any irregular or missing signals?

Yes

- Replace the Cam Position Sensor.

- Perform POWERTRAIN VERIFICATION TEST. See: A L L Diagnostic Trouble Codes ( DTC ) > Verification Tests > Powertrain Verification Test

No

- Go To 7

7. CRANKSHAFT POSITION SENSOR

If there are no possible causes remaining, view repair.

Repair

- Replace the Crankshaft Position Sensor.

- Perform POWERTRAIN VERIFICATION TEST. See: A L L Diagnostic Trouble Codes ( DTC ) > Verification Tests > Powertrain Verification Test

8. (K24) CKP SIGNAL CIRCUIT SHORTED TO BATTERY VOLTAGE

pic 4

Turn the ignition off.

Disconnect the C2 PCM harness connector.

Disconnect the CKP Sensor harness connector.

Ignition on, engine not running.

Measure the voltage on the (K24) CKP Signal circuit in the Sensor harness connector.

Wiggle the related wire harness while taking this measurement.

Is the voltage above 0 volts?

Yes

- Repair the short to battery voltage in the (K24) CKP Signal circuit.

- Perform POWERTRAIN VERIFICATION TEST. See: A L L Diagnostic Trouble Codes ( DTC ) > Verification Tests > Powertrain Verification Test

No

- Go To 9

9. (K24) CKP SIGNAL CIRCUIT OPEN

pic 5

Turn the ignition off.

CAUTION: Do not probe the PCM harness connectors. Probing the PCM harness connectors will damage the PCM terminals resulting in poor terminal to pin connection. Install Miller Special Tool #8815 to perform diagnosis.

Measure the resistance in the (K24) CKP Signal circuit from the CKP harness connector to the appropriate terminal of special tool #8815.

Wiggle the wire harness while taking this measurement.

Is the resistance below 1.0 ohm?

Yes

- Go To 10

No

- Repair the excessive resistance in the (K24) CKP Signal circuit.

- Perform POWERTRAIN VERIFICATION TEST. See: A L L Diagnostic Trouble Codes ( DTC ) > Verification Tests > Powertrain Verification Test

10. (K24) CKP SIGNAL CIRCUIT SHORTED TO GROUND

pic 6

Measure the resistance between ground and the (K24) CKP Signal circuit in the CKP Sensor harness connector.

Wiggle the related wire harness while monitoring the resistance value.

Does the resistance ever go below 100 ohms?

Yes

- Repair the short to ground in the (K24) Signal circuit.

- Perform POWERTRAIN VERIFICATION TEST. See: A L L Diagnostic Trouble Codes ( DTC ) > Verification Tests > Powertrain Verification Test

No

- Go To 11

11. (K24) CKP SIGNAL CIRCUIT SHORTED TO THE (F855) 5-VOLT SUPPLY CIRCUIT

pic 7

Measure the resistance between the (F855) 5-volt Supply circuit and the (K24) CKP Signal circuit in the CKP harness connector.

Wiggle the related wire harness while taking this measurement.

Is the resistance below 5.0 ohms?

Yes

- Repair the short between the (F855) 5-volt Supply circuit and the (K24) CKP Signal circuit.

- Perform POWERTRAIN VERIFICATION TEST. See: A L L Diagnostic Trouble Codes ( DTC ) > Verification Tests > Powertrain Verification Test

No

- Go To 12

12. PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and Ground circuits.

Were there any problems found?

Yes

- Repair as necessary.

- Perform POWERTRAIN VERIFICATION TEST. See: A L L Diagnostic Trouble Codes ( DTC ) > Verification Tests > Powertrain Verification Test

No

- Replace and program the Powertrain Control Module.

- Perform POWERTRAIN VERIFICATION TEST. See: A L L Diagnostic Trouble Codes ( DTC ) > Verification Tests > Powertrain Verification Test

_____________________________

Let me know if this helps or if you have other questions.

Take care,

Joe

Images (Click to make bigger)

Thursday, January 9th, 2020 AT 7:13 PM