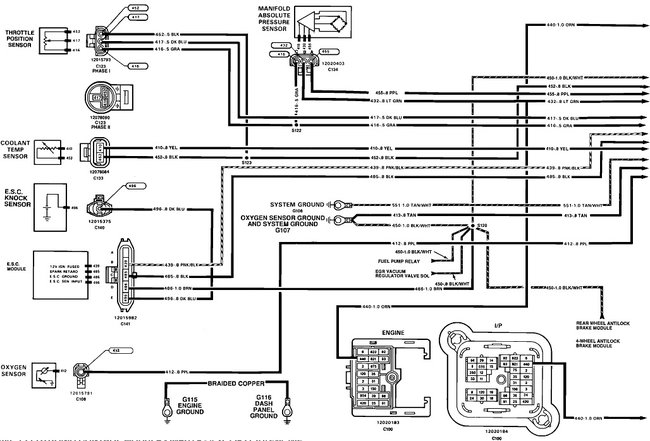

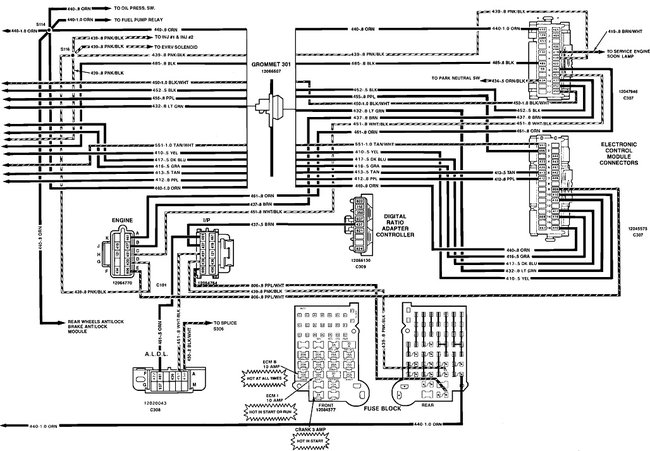

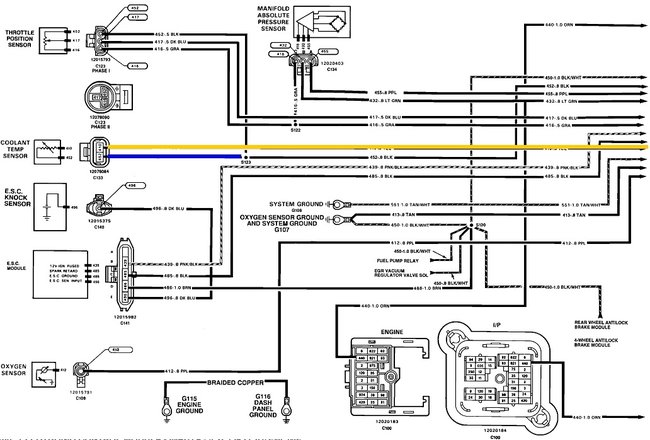

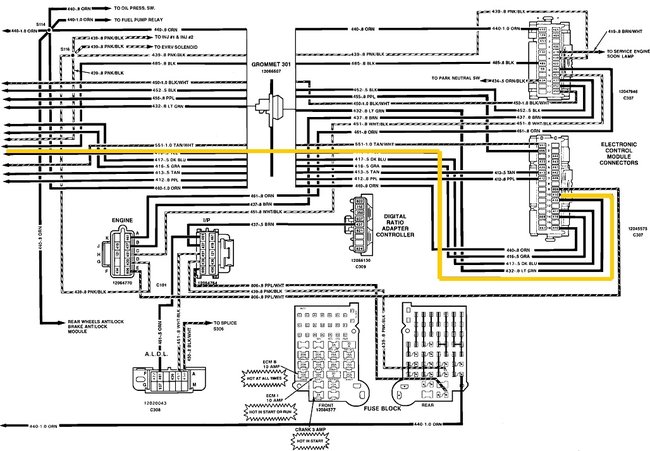

This is rarely caused by the sensor because temperature sensors have just one component inside them. This is almost always a problem with the wiring or connector terminals. These first two diagrams are for the Engine Computer's sensors. The last two are the same, but I highlighted the wires where we're going to find the cause of the problem.

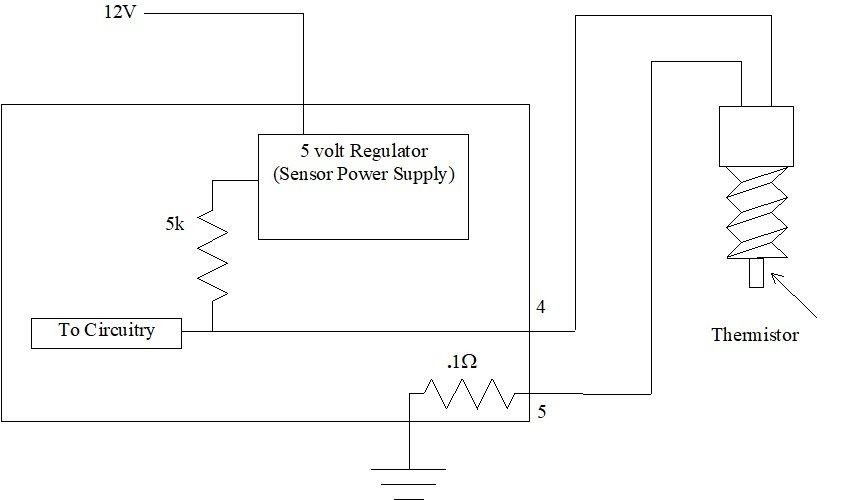

This circuit is fed with a carefully-regulated 5.0 volts from the Engine Computer. There's an internal resistor that drops some of that 5,0 volts, but only when the coolant temperature sensor circuit has no break in it. With that normal operation, the sensor will draw the signal voltage down to between 0.5 and 4.5 volts. Anything outside that range is what gets detected as a defect and sets the diagnostic fault code.

With a break in the circuit, there's no current flow through it, therefore there's no voltage dropped across the internal resistor. That leaves the full 5,0 volts to be seen as the signal voltage, which is outside the acceptable range. The fault code "CTS voltage high" code will be set. At the same time, when you use a digital voltmeter to measure that signal voltage right at the sensor, you're going to find close to 0.0 volts.

For any voltage tests to be valid, you can't create any "open circuits". meaning unplugging anything. You have to back-probe through the back of the connector to take the readings. For the benefit of others researching this topic, here's a link to an article on how to use a digital voltmeter:

https://www.2carpros.com/articles/how-to-use-a-voltmeter

The circuit in question are the wires I highlighted in the last two diagrams. The blue wire is the sensor's ground wire that goes to ground through the computer. From the splice and to the right of the blue section, we don't have to worry about that. The ground wire is shared with the throttle position sensor. If that section had a defect, you'd be getting a fault code for the TPS too.

To verify you're taking readings in the right circuit, back-probe the yellow wire in the CTS connector. The meter's negative probe must be on the battery's negative post or on any clean, rust-free point on the engine. Ignition switch must be in the "run" position. If the problem is not occurring at this time, you're going to find something between 0.5 and 4.5 volts. Typical would be around 2.5 to 3.5 volts. The exact value is unimportant as long as it's not 0.0 or 5.0 volts.

When the problem is occurring, the computer will be seeing 5.0 volts, but you'll measure 0.0 volts at the sensor. Watch the meter while you wiggle and move that yellow wire. You're looking for the area where you can manipulate it and cause the voltage to change. The best suspect is the terminals in the connector itself. Next would probably be where the wires go through the firewall as that section flexes as the engine rocks.

When you get the defect to act up, there's two possible voltages you're going to find at the yellow wire in the CTS connector. That is 5.0 volts or 0.2 volts. Consider 0.2 volts as 0.0 volts. That two tenths is the result of the circuitry inside the computer, and isn't part of this story. There is going to be 5.0 volts from the computer all the way up to the break in the circuit, and 0.0 volts everywhere after that break. If the entire yellow wire is good, you'll find 5.0 volts when you back-probe that terminal in the CTS connector. That means the break has to be in the terminal for the yellow wire, the sensor itself, (unlikely), the terminal for the black wire, or the black wire or a corroded splice. The most likely finding will be 5.0 volts on the yellow wire and 0.0 volts on the black wire. Since you already replaced the sensor, that leaves the two pairs of mating terminals as the logical suspects If you find 0.0 volts on the yellow wire, that wire has the break in it. If interpreting the readings is still confusing, just tell me what you find on the two wires Remember, those readings have to be taken with the connector plugged in.

Images (Click to make bigger)

Friday, May 14th, 2021 AT 7:54 PM