This post is seven years old, so I suspect the problem has been handled. To clarify a few things, the decisive clue was the engine speeding up when shifting to third gear, then staying in second gear. That is indeed "limp mode", and is the result of excessive slippage in a clutch pack. That slippage is due to worn clutch plates. The only way to get it out of limp mode is to turn the ignition switch off, then restart the engine.

As with most other innovations since the 1950s that truly benefited owners, this computer-controlled transmission was developed by Chrysler, then others copied it years later. With all older hydraulically-controlled transmissions, that "engine runaway" during up-shifts gradually became worse and worse over a period of a few years, so we had plenty of warning that clutch plate wear was taking place. We could ignore the slipping and keep driving for a long time.

With Chrysler's design, the computer monitored the volume of fluid it takes to apply each of the four clutch packs. That is how it always knows how much wear has taken place. In the case of this original post, there was increased slipping taking place when up-shifting into third gear. Since that was a learned variable, the computer would apply third gear, then increase the delay time before it released second gear. As a result, all you felt was a nice crisp, solid shift.

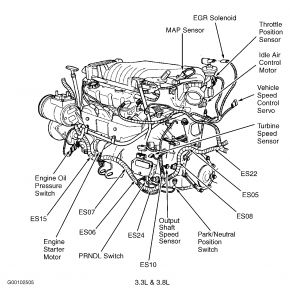

The problem was you never got that two or three-year notice that wear was taking place. The computer continued to update the shift schedules, ... Until the day came when it couldn't update any further to overcome the severe wear. That is when the first engine runaway occurred. That slippage is detected by comparing the input speed sensor's readings to the output sensor's readings, and multiplying by the gear ratio. When the two readings don't agree, a fault code for "gear ratio error" is set, and the computer puts it in second gear so the vehicle can be driven slowly to a repair shop without needing a tow truck. If there was no limp mode, too many people would continue to beat the vehicle and force it to move. That slippage would overheat the fluid, then do extensive damage to the rotating drums, resulting in an even more expensive repair.

A lot of people think replacing the speed sensors will solve gear ratio fault codes, but in fact, those codes are detected by the readings from two properly-working sensors. Replacing the messengers doesn't fix the message. If a sensor circuit has a problem, that will be detected as an electrical fault, and an entirely different fault code will be set. It will still result in the system going into limp mode, but for an entirely different reason.

The key is in reading the fault codes so you know what is causing the problem. Each code will point to an electrical problem or a mechanical problem. Neither of those is going to be solved by adding a can of "mechanic-in-a-can". If the fiber clutch plates are worn down, no chemical is going to put that material back. With older transmissions, if you never hit wide-open-throttle for many years, varnish can build up in part of the throttle valve bore, then, when you DO finally hit WOT, that spring-loaded valve can stick and cause real late up-shifts, and harsh, early down-shifts. Chemical additives can dissolve that varnish and restore normal shifting.

With Chrysler's computer-controlled transmissions, every shift valve always travels fully from one extreme to the other, so there is no chance for varnish to build up in a bore and cause a valve to stick. Shift harshness is adjusted by pulsing various valves fully-on, then fully-off, repeatedly, very quickly. That "modulates" the shift quality, and is called "pulse-width modulation", (PWM). That is the light ratcheting, or buzzing noise you hear when shifting into gear or when approaching a stop.

So the chemical additives won't fix worn clutch plates or remove debris in a bore causing a valve to stick. That only leaves the rubber lip seals on the clutch drums. Those flex very little so even if they become hardened from age, they aren't likely to crack and break apart. If they wear down, they can't seal properly. If a clutch pack is near the end of its life, a little leakage past a lip seal could be just enough to cause enough slippage to send the system into limp mode. A can of additive might overcome that leakage for a while, but that is not a permanent fix.

You can get an idea of how much life is left in the clutch packs by reading the "clutch volume index", (CVI), on a scanner. I use Chrysler's DRB3 for all of my vehicles, but I suspect this can be done with the more expensive aftermarket scanners too. You'll get a set of four numbers corresponding to the four clutch packs. A transmission specialist can tell from those numbers if it's getting time to need a rebuild.

The last thing to consider is the lock-up clutch in the torque converter. That is another Chrysler innovation to improve fuel mileage, going back to the mid '70s. To improve comfort, that clutch is also pulse-width modulated when it engages at its lower speeds, typically around 35 - 40 mph. The correct transmission fluid must be used to provide the desired friction characteristics. Using the wrong fluid often causes a hard chatter or shudder during engagement, and that may continue as long as that minimum speed is maintained. Solid lock-up occurs at higher speeds, so the shudder isn't felt then. I've never heard of anyone solving that shudder by adding a can of additives, but that doesn't mean it can't happen. Normally the only fix for that shudder is to replace the fluid, and the filter as long as you're in there.

Tuesday, March 14th, 2017 AT 5:13 PM