TEST TC-35A: NO VEHICLE SPEED SENSOR SIGNAL

NOTE: For connector terminal identification, see CONNECTOR

IDENTIFICATION . For wiring diagram, refer to WIRING DIAGRAMS .

WARNING: Keep hands and feet clear of rotating wheels.

Raise and support vehicle under lower control arms, allowing drive wheels to spin free. Start

engine. Using scan tool, read Vehicle Speed Sensor (VSS). Put transmission in any forward

gear. If scan tool displays more than zero MPH, go to next step. If scan tool does not display

more than zero MPH, go to step 5).

1.

Condition to set trouble code is not present at this time. NO VEHICLE SPEED SENSOR

SIGNAL DTC sets if there is no signal from Vehicle Speed Sensor (VSS) for more than 11

seconds (without electronically controlled transmission) or no VSS signal is present from

Transmission Control Module (TCM) for more than 11 seconds (equipped with electronically

controlled transmission). If vehicle is NOT equipped with an electronically controlled

automatic transmission, go to next step. If vehicle is equipped with an electronically controlled

automatic transmission, possible causes are: open or shorted signal circuit, speedometer pinion

factor not programmed, output speed sensor circuit problem, failed Powertrain Control Module

(PCM) or failed TCM. Go to step 4).

2.

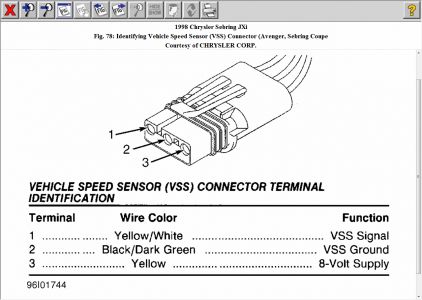

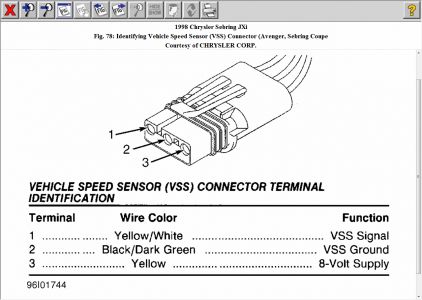

Possible causes are: open or shorted signal circuit, speedometer pinion damaged, open 8-volt

supply circuit, open sensor ground circuit, failed VSS, failed Powertrain Control Module

(PCM), faulty connections or wiring. Go to next step.

3.

Inspect all related wiring and connectors and repair as necessary. If no problems were found

with wiring and connectors, see INACTIVE TROUBLE CODE CONDITION under SELFDIAGNOSTIC

SYSTEM. Test is complete. Perform TEST VSS-VER . If related wiring and

connectors were repaired, Perform TEST VSS-VER .

4.

If vehicle is equipped with an electronically controlled automatic transmission, go to next step.

If vehicle is not equipped with an electronically controlled automatic transmission, go to TEST

TC-35B.

5.

Using scan tool, read transmission trouble codes. If transmission Diagnostic Trouble Codes

(DTCs) 50-58 are present or pinion factor is not programmed, repair transmission as required.

See appropriate article in AUTOMATIC TRANSMISSION Section. If transmission Diagnostic

Trouble Codes (DTCs) 50-58 are not present or pinion factor is programmed, go to next step.

6.

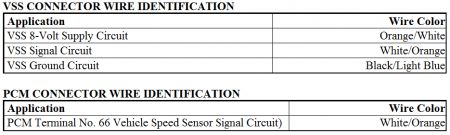

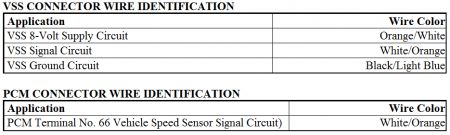

Turn ignition off. Disconnect Transmission Control Module (TCM) connector. Connect one

end of a jumper wire to TCM connector terminal No. 58. See TCM CONNECTOR WIRE

IDENTIFICATION table. Turn ignition on. Using scan tool, read VSS signal. While

observing scan tool display, tap other end of jumper wire to ground. If scan tool does not

display more than zero MPH, go to next step. If scan tool displays more than zero MPH, repair

transmission as required. See appropriate article in AUTOMATIC TRANSMISSION Section.

7.

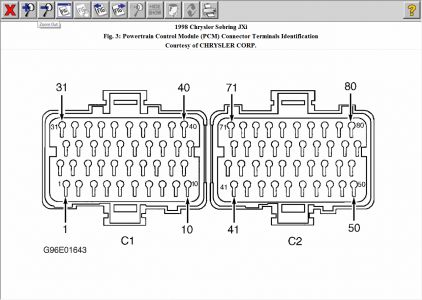

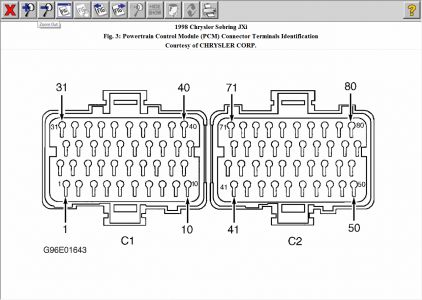

Turn ignition off. Disconnect PCM connector. Using an ohmmeter, check resistance of VSS

signal circuit between PCM connector terminal No. 66 and TCM connector terminal No. 58.

See TCM CONNECTOR WIRE IDENTIFICATION table. If resistance is less than 5 ohms,

go to next step. If resistance is 5 ohms or more, repair open VSS signal circuit. Perform TEST

VSS-VER .

8.

CRUISE CONTROL SYSTEMS - EXCEPT COUPE -1998 Chrysler Sebring JXi Page 1 of 2

4/23/2010

Using an ohmmeter, check resistance of VSS signal circuit between TCM connector terminal

No. 58 and ground. If resistance is less than 5 ohms, repair short to ground on VSS signal

circuit. Perform TEST VSS-VER . If resistance is 5 ohms or more, replace PCM. Perform

TEST VSS-VER .

9.

TCM CONNECTOR WIRE IDENTIFICATION

Application Wire Color

TCM Terminal No. 58 Vehicle Speed Sensor Signal Circuit) White/Orange

CRUISE CONTROL SYSTEMS - EXCEPT COUPE -1998 Chrysler Sebring JXi Page 2 of 2

4/23/2010

Friday, April 23rd, 2010 AT 4:14 PM