Hello

There are two different engines for that, a V6-2.7L VIN R and a V6-3.2L VIN J. I am going to use the 2.7L

Why did you change the plugs and coils? Was this doing this prior to this? If it wasn't then it has to be something with this. I am going to assume this.

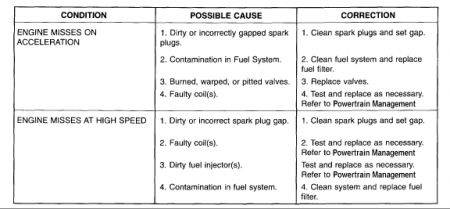

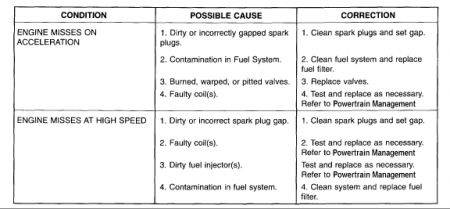

The codes state all are misfiring. I have attached the troubleshooting for this and as you see they all speak of faulty coils. Also, plugs and plug gap. Again assuming things were fine before.

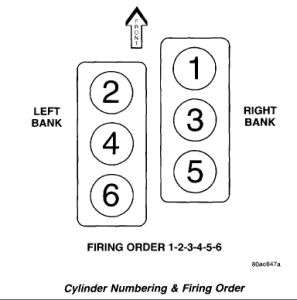

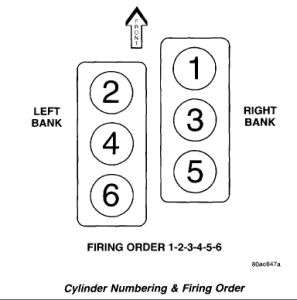

I have attached the proper firing order to ensure all on are the right way. I have attached the plug type and gap.

SPARK PLUGS-PLATINUM

DESCRIPTION

All engines use platinum resistor spark plugs. They have resistance values of 6,000 to 20,000 ohms when checked with at least a 1000 volt tester. For spark plug identification and specifications, Refer to the Specifications.

Do not use an ohmmeter to check the resistance of the spark plugs. This will give an inaccurate reading .

The spark plugs are double platinum and have a recommended service life of 100,000 miles for normal driving conditions per schedule A. The spark plugs have a recommended service life of 75,000 miles for severe driving conditions.

A thin platinum pad is welded to both or center electrode end(s) as shown. Extreme care must be used to prevent spark plug cross threading, mis-gaping and ceramic insulator damage during plug removal and installation.

CAUTION : Cleaning of the platinum plug may damage the platinum tip.

My suggestion is remove and ensure you have the correct plug for this model. Some plugs just don't work well in some cars thus, use the OEM specific. Make sure they are torque correctly and coils installed security and correctly.

Electrode Gap 1.21-1.47 mm (0.048-0.058 in) Torque 17.6 Nm (13 ft lb) Tighten Coil Screws 6.2 Nm (55 in lb) Plug Type RE10PMC5

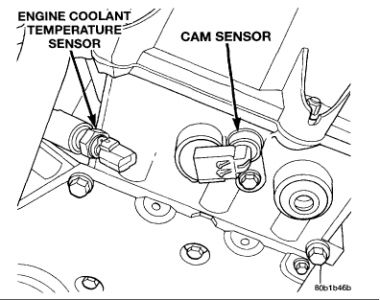

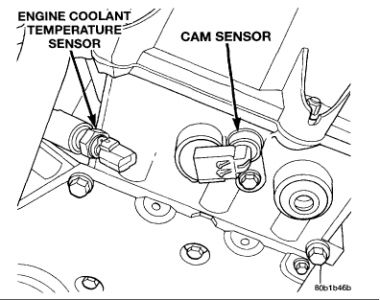

It may be your camshaft position sensor. The camshaft position sensor provides cylinder identification to the Powertrain Control Module (PCM). The sensor generates pulses as groups of notches on the camshaft sprocket pass underneath it. The PCM keeps track of crankshaft rotation and identifies each cylinder by the pulses generated by the notches on the camshaft sprocket.

When metal aligns with the sensor, voltage goes low (less than 0.3 volts ). When a notch aligns with the sensor, voltage spikes high (5.0 volts ). As a group of notches pass under the sensor, the voltage switches from low (metal) to high (notch) then back to low. The number of notches determine the amount of pulses. If available, an oscilloscope can display the square wave patterns of each timing events.

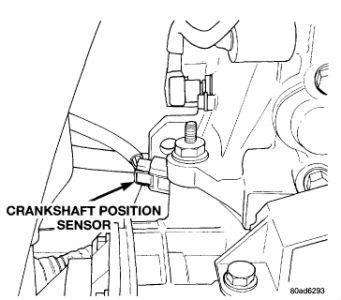

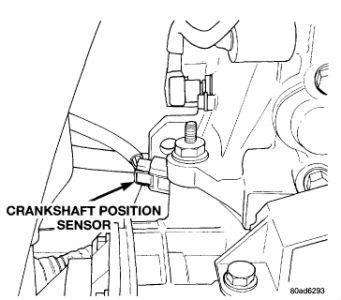

The crankshaft sensor is located on the passengers side of the transmission housing,. above the differential housing. The bottom of the sensor is positioned next to the drive plate.

The crankshaft position sensor detects slots cut into the transmission driveplate extension. There are 3 sets of slots. Each set contains 4 or 5 slots, for a total of 13 slots. Basic timing is set by the position of the last slot in each group. Once the Powertrain Control Module (PCM) senses the last slot, it determines crankshaft position (which piston will next be at TDC) from the camshaft position sensor input. The 4 pulses generated by the crankshaft position sensor represent the 690, 490, 290, and 90 BTDC marks. It may take the PCM one engine revolution to determine crankshaft position.

The PCM uses crankshaft position reference to determine injector sequence and ignition timing. Once the PCM determines crankshaft position, it begins energizing the injectors in sequence

I hope this helps. Again, my suggestion is to first ensure the correct plug, gap, proper installation of coils. Once installed, take a spray bottle of water and with it running spray over the wires. If it freaks out you have sparks jumping and it is bad. . ...new or not.

Then check the camshaft sensor and then the crankshaft sensor.

SPONSORED LINKS

Tuesday, October 28th, 2008 AT 8:20 PM