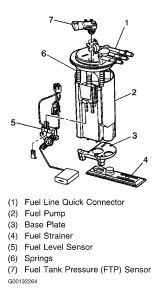

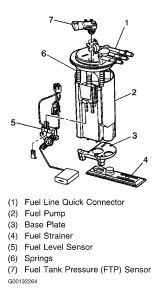

FUEL SENDER ASSEMBLY

Removal

Release fuel system pressure. See FUEL SYSTEM PRESSURE RELEASE . Remove the fuel tank. See FUEL TANK . Clean all of the fuel pipe connections, all of the hose connections, and all of the areas surrounding the connections before disconnecting the connections in order to avoid possible contamination of the fuel system.

Disconnect the fuel sender quick-connect fittings. See FUEL LINE DISCONNECT FITTINGS . Disconnect the fuel sender electrical connector. Disconnect the fuel tank pressure sensor electrical connector. See Fig. 22 . Using Fuel Sender Lock Ring Tool (J-39348), remove the fuel sender lock ring.

CAUTION:DO NOT handle the fuel sender assembly by the fuel pipes. The amount of leverage generated by handling the fuel pipes could damage the joints.

Remove the fuel sender assembly and seal from the fuel tank. Discard the fuel sender assembly seal. Clean and inspect the fuel sender sealing surfaces.

Installation

Position the NEW fuel sender seal on the fuel tank. DO NOT fold over or twist the fuel pump strainer when installing the fuel sender assembly, as this will restrict fuel flow. Also, assure that the fuel pump strainer does not block full travel of float arm.

Install the fuel sender assembly and the fuel sender lock ring using the fuel sender lock nut wrench. Connect the quick-connect fittings at the fuel sender. Connect the fuel sender electrical connector. Connect the fuel tank pressure sensor electrical connector. Install the fuel tank. See FUEL TANK .

Add fuel to the fuel tank. Install the fuel tank filler pipe cap. Connect the negative battery cable. Perform the following procedure in order to inspect for leaks: Turn ON the ignition, with the engine OFF for 2 seconds. Turn OFF the ignition for 10 seconds. Turn ON the ignition, with the engine OFF. Inspect for fuel leaks.

Saturday, November 9th, 2019 AT 2:16 PM

(Merged)