This condition exists when the engine has been rotated with the distributor removed.

Install a new o-ring on the distributor housing.

Rotate the crankshaft to position the number one cylinder on the TDC of its compression stroke. This may be determined by inserting a rag into the number one spark plug hole and slowly turn the engine crankshaft. When the timing mark on the crankshaft pulley aligns with the 0 ° mark on the timing scale and the rag is blown out by the compression, the number one piston is at top-dead-center (TDC).

If you are unsure when TDC is reached, remove the valve cover and watch the rocker arms for the number one cylinder. If the valves move as the crankshaft timing marker approaches the scale, the number one cylinder is on its exhaust stroke. If the valves remain closed as the timing mark approaches the scale, then the number one cylinder is approaching TDC of the compression stroke.

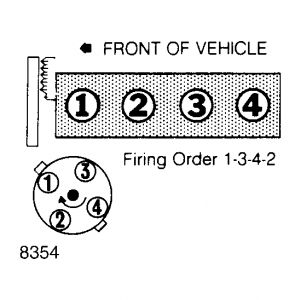

Turn the rotor so that it will point to the number one terminal of the distributor cap.

Install the distributor into the engine block. It may be necessary to turn the rotor, a little in either direction, in order to engage the gears.

Tap the starter a few times to ensure that the oil pump shaft is mated to the distributor shaft.

Bring the engine to number one TDC again and check to see that the rotor is indeed pointing toward the number one terminal of the cap.

With the respective marks aligned, install the hold-down clamp and bolt finger-tight.

SPONSORED LINKS

Friday, January 29th, 2010 AT 12:03 AM