Okay, where did the 16 code you gave me come from?

If they went by the code number, very rarely does a code identify a failed part, just a failed system. Diagnostics need to be done to verify the failure before throwing any parts to it.

I posted below a description and flow chart for you.

Roy

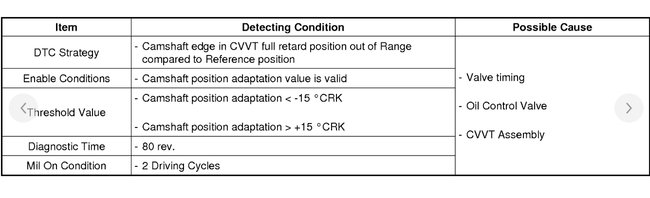

P0335 Crankshaft Position Sensor 'A' Circuit

Inspection/Repair - Component Inspection

Component Inspection

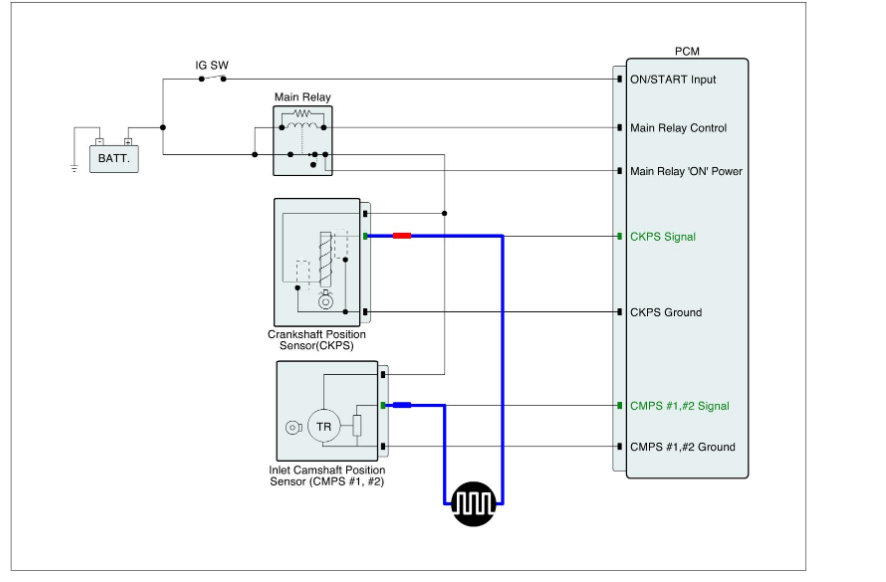

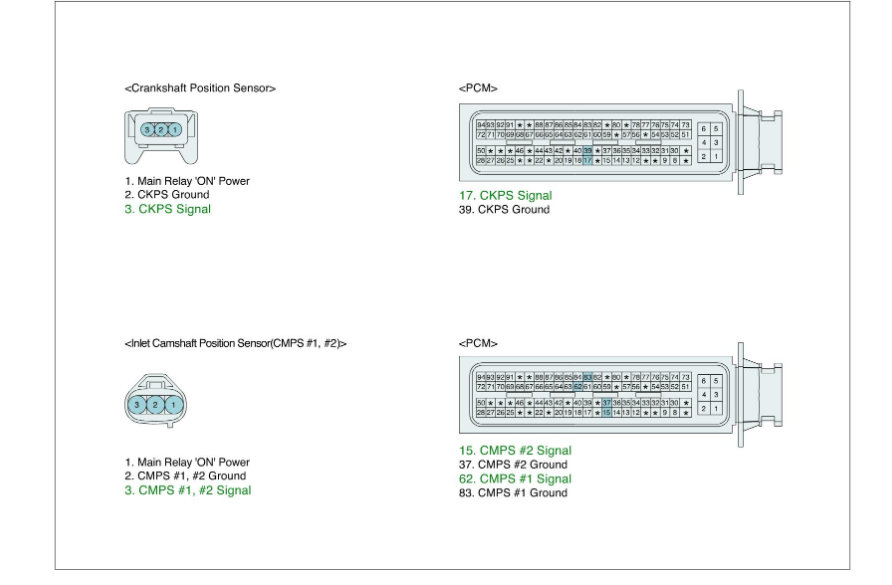

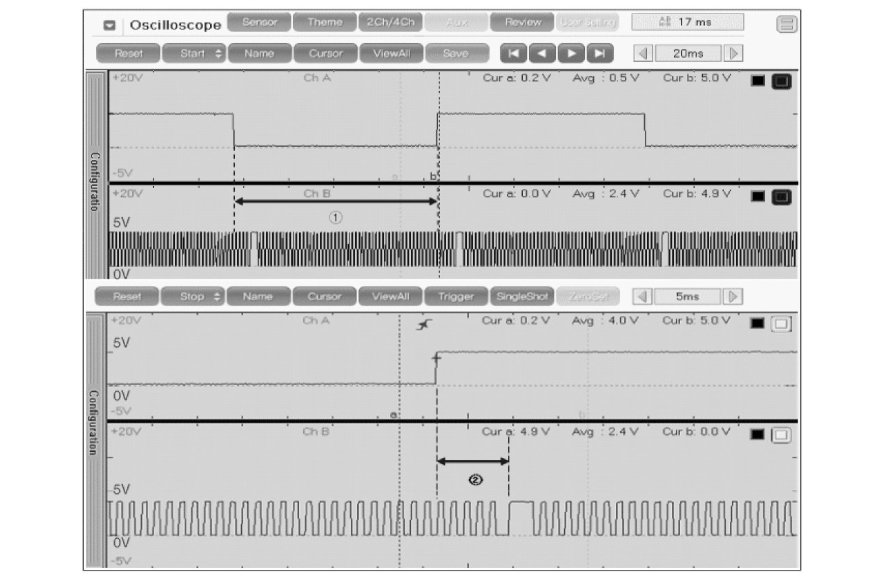

1. Set up an oscilloscope as follows :

(1)Channel A (+): Signal terminal of the CMPS #1 (back probe), (-): ground

(2)Channel B (+): Signal terminal of the CKPS (back probe), (-): ground

2. Start the engine and check for signal waveform compared with reference waveform as below.

ImageOpen In New TabZoom/Print

1 There are 60 signals of CKPS (Including missing tooth) during the semi-cycle of CMPS #1.

2 There are 3 - 5 signals of CKPS between the switching point of CMPS #1 and the missing tooth of CKPS.

ImageOpen In New TabZoom/Print

imageOpen In New TabZoom/Print

3. Is the signal waveform normal?

ImageOpen In New TabZoom/Print

Images (Click to make bigger)

SPONSORED LINKS

Friday, January 3rd, 2020 AT 3:09 PM