Hi and thanks for using 2CarPros.

If it is bogging down, make sure there are no obstructions in the air filter box, air inlet tube, or throttle body. Also, I would suggest confirming the fuel pump pressure to the engine. If it is weak, this can happen. Even though the pump was replaced, I would check.

Here is a link that shows in general how to check fuel pressure:

https://www.2carpros.com/articles/how-to-check-fuel-system-pressure-and-regulator

Also, here is a link that shows common causes of low power/bogging down. It covers many things. Read through it and see if anything helps.

https://www.2carpros.com/articles/engine-has-low-power-output

Here are the directions specific to your vehicle for testing fuel pressure. All attached pictures correlate with these directions.

____________________

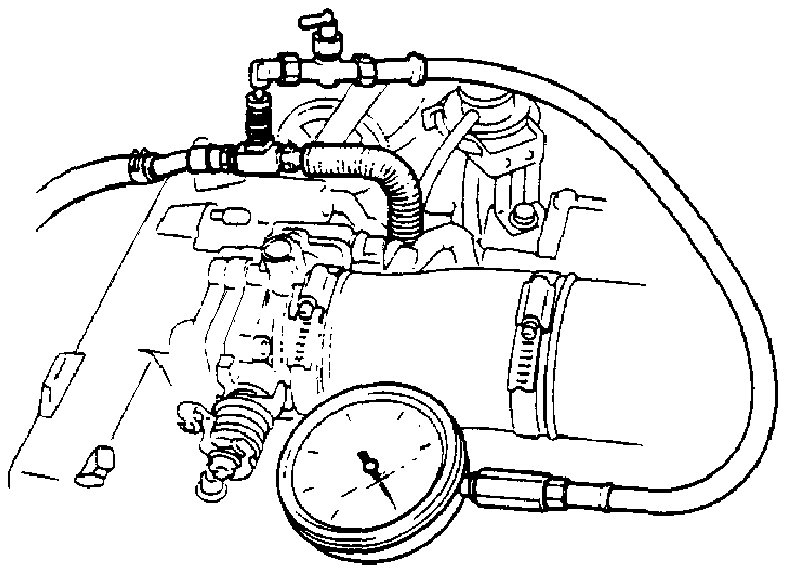

Connecting Fuel Pressure Gage

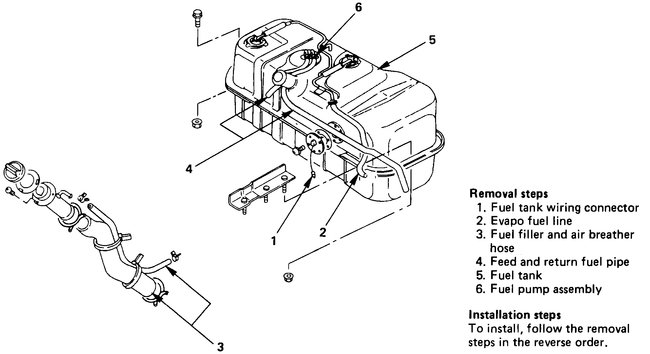

1. Relieve fuel system pressure.

A. Remove fuel pump fuse from fuse block in instrument panel.

B. Crank engine until it stalls and then for an additional 3 seconds.

C. Disconnect negative (-) battery cable.

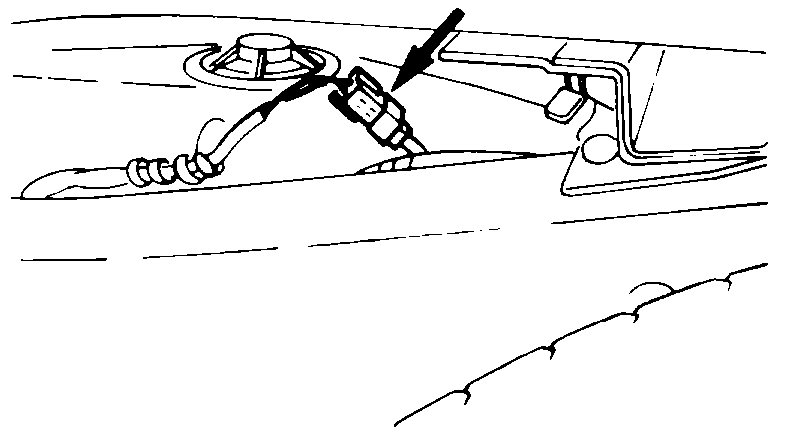

2. Connect a fuel pressure gage.

Fuel Pressure Gauge : J-35957-1

Fuel Rail Access Fitting : J-35957-2

Note:

- When pulling out the fuel hose, cover up the joint with a rag to prevent gasoline from spraying. Once fuel pressure gage is connected, reconnect negative (-) battery cable and reinstall fuel pump fuse into fuse block. Before removing fuel pressure gage, relieve fuel system pressure.

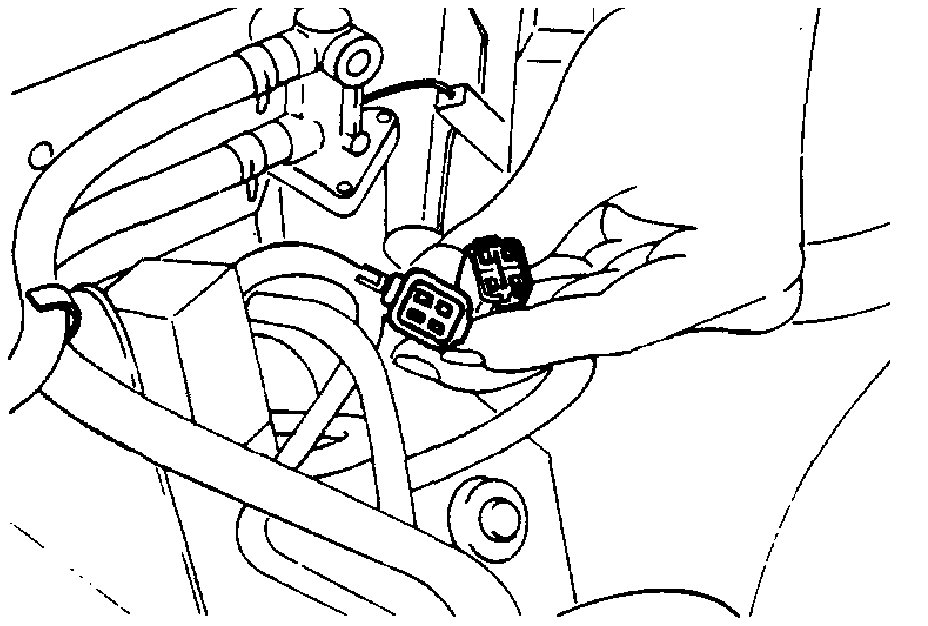

2. Disconnect the Vacuum Switching Valve (VSV) harness at connector.

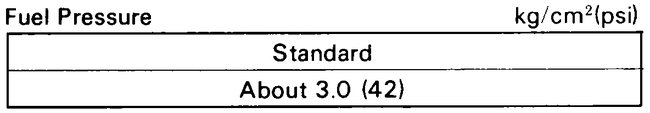

Measurement

Start the engine and measure fuel pressures at idling.

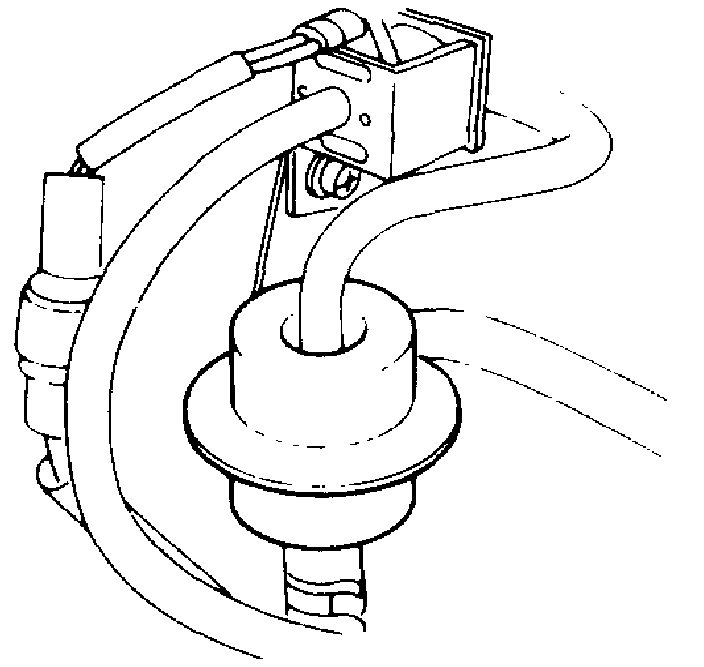

1. Disconnect the vacuum hose from the pressure regulator and plug it.

Fuel Pressure: About 300 kPa (42 PSI)

2. Reconnect the vacuum hose to the pressure regulator.

Fuel Pressure: About 250 kPa (35 PSI)

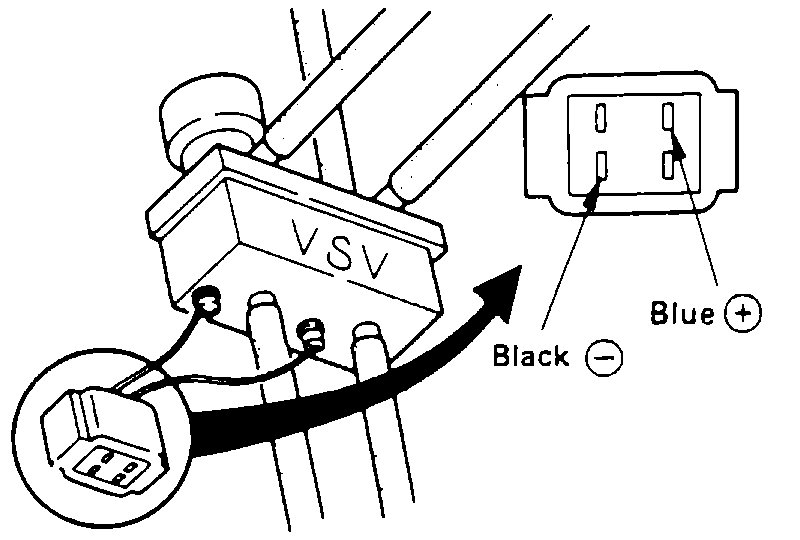

3. Apply battery voltage to the VSV connector.

Fuel Pressure: About 300 kPa (42 PSI)

4. Disconnect the vacuum hose from the fuel pressure control valve and plug it. Stop engine to check for fuel leakage and make sure that fuel pressure remains above 250 kPa (35 psi) for 4 min. after engine is turned off.

Note: The following method can be used to operate the fuel pump without running the engine.

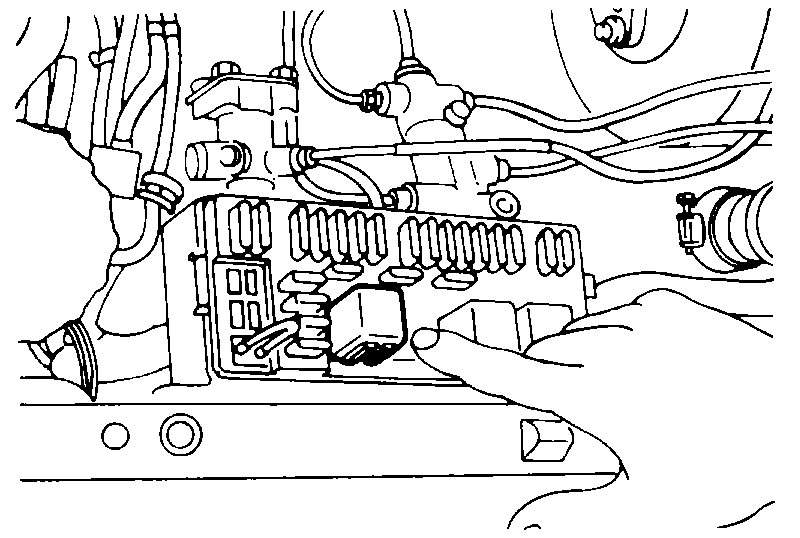

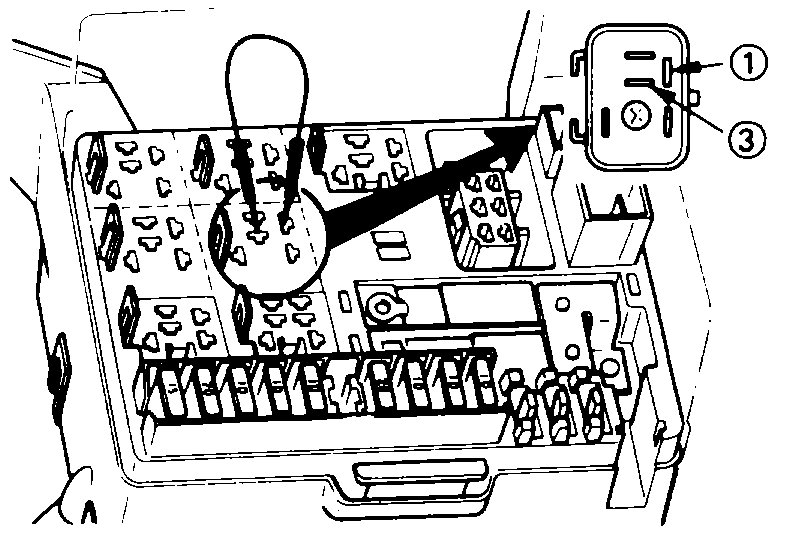

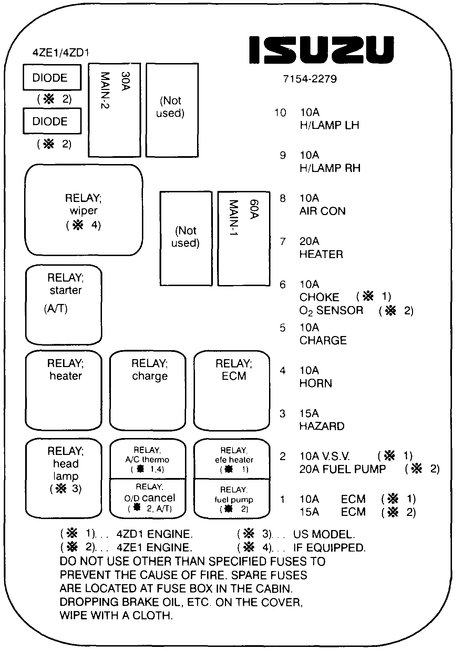

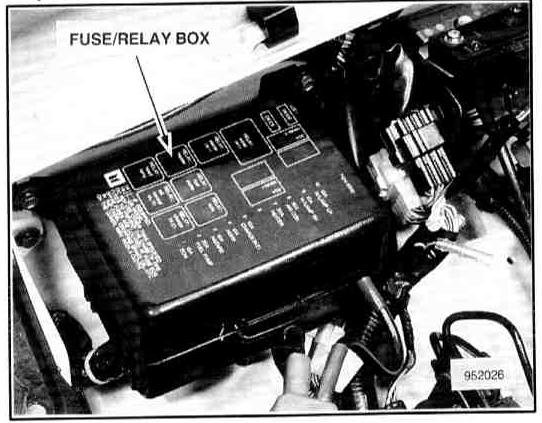

1. Remove the fuel pump relay from the fuse and relay box.

2. Connect a fused jumper between terminals (1) (1.25BY) and (3) (1.25BL) of the connector.

Inspection

When Fuel Pressure Does Not Reach Standard Level

Check fuel pressure with battery voltage applied directly to the fuel pump using fused jumper wires.

1. If fuel pressure reaches normal level:

- Check fuel pump circuit and correct as necessary.

- Fuel pump relay may be defective.

2. If fuel pressure remains unchanged:

- Restrictions in hose on intake side of fuel pump, Clean (Restrictions in intake hose may cause abnormal vibrations of the hose).

- Fuel pressure control valve defective, replace.

- Fuel pump malfunctioning, replace.

________________________________

Let me know if this helps or if you have other questions.

Take care,

Joe

Images (Click to make bigger)

Thursday, November 29th, 2018 AT 6:57 PM