Yes, it's standard procedure to replace the receiver / drier anytime the system is opened, but many mechanics try to reduce your cost by not doing that. The result is you think they did poor quality work, and you're angry with them if your vehicle is the one out of a hundred that develops another problem. To avoid that some mechanics have to avoid being conscientious to your wallet and they just replace everything that might cause a problem later.

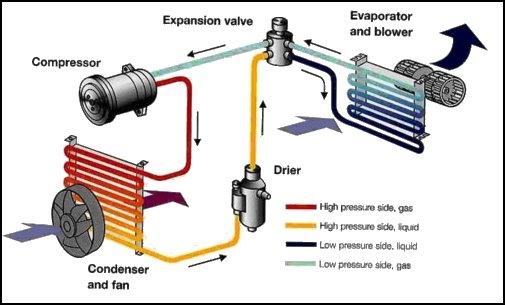

If the drier disintegrated as they said, it did that a while ago and the problem would have been there as soon as they replaced the compressor. The material would plug the "H-valve" with its tiny orifice, not the hoses.

You also have to look at why the compressor was replaced. The electric clutch causes a lot more trouble than the compressor itself. That would not require a new drier. If the compressor was coming apart inside there could be metal chips circulating in the system. Those would be trapped in the filter in the drier and could plug it. The cooling occurs at the point of a controlled and variable restriction which is that H-valve, but if there's some other restriction in the system, cooling will take place there. If the filter in the drier is plugged you will find frost forming on the hose leaving it.

The main reason the drier is replaced is it has a desiccant that removes moisture from the refrigerant. It can hold about ten droplets of water. One droplet is way too much in the system. It will freeze at the orifice where it gets real cold. That will stop the flow of refrigerant until it warms up, melts, and circulates back around again. That will cause intermittent cooling. We get that moisture out by pumping the system into a huge vacuum for a half hour before we put the refrigerant in. Under vacuum water boils at 77 degrees and can be sucked out as a vapor.

Given the recent repairs, I'm more inclined to believe a connection is leaking and the new refrigerant leaked out while the van was sitting in the parking lot waiting to be picked up. Pressure tests will verify that. Mechanics have electronic leak detectors to find those leaks but they don't always show up right away. A leak can be so small that natural air flow in the building blows the leaking refrigerant away, and the leak won't show up.

I wouldn't agree to having any more parts replaced until the system is properly diagnosed and the pressures are tested. If the system is still under full pressure, be sure the compressor is running. You'll see the clutch cycle on and off once or twice per minute. (Some run continuously). If the compressor doesn't cycle on or stay on, the system is low on charge and a safety cut-out switch is preventing it from running. That would point to a leak. The problem with leaks is there are often more than one but a lot of mechanics stop looking after they find the first one. Condensers in front of the radiator often corrode through, and hoses commonly leak next to the metal crimped-on fittings. The clue is you will see oil residue around the leak.

SPONSORED LINKS

Monday, April 29th, 2013 AT 12:43 PM