Possibly. I can share the common cause of this, but you're working on a much newer model. I don't know if GM has made changes in this regard.

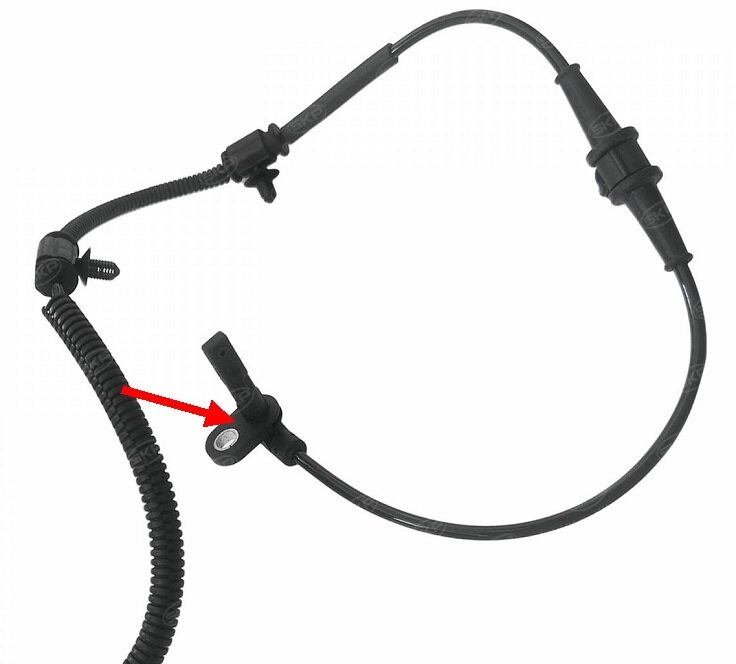

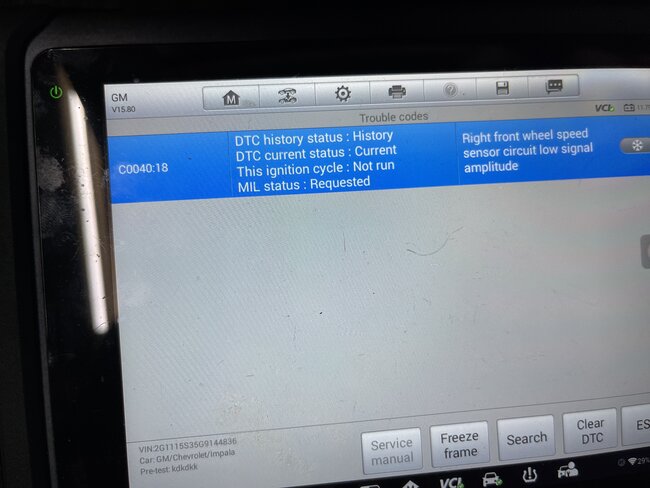

Back as far as the mid '90s, GM has built their front wheel speed sensors onto the backs of the front wheel bearing assemblies. They develop just barely enough signal voltage for the computer to be able to read. With a little play that develops in the bearings, which is normal, the inner tone wheel, a stamped steel ring, can move away from the sensor just enough for the signal strength to become too weak to be read by the computer. This is where you'll see the 0 mph road speed. You'll get a diagnostic fault code for a missing signal. That is very different from a fault code related to the electrical integrity of the circuit, meaning a cut wire or corroded connector terminal. A break is detected right away, then the yellow "ABS" warning light will go through its six-second self-test, turn off, then turn back on right away. With the missing signal fault code, the warning light won't turn on until the vehicle starts to move faster than 9 - 15 mph.

This problem was extremely common and could happen to a wheel bearing in as little as 15,000 miles, including to the replacement assemblies. The dealers' scrap metal bins were full of them. Funny thing is, those bearings would work perfectly fine in a car that didn't have anti-lock brakes. You could pop the speed sensor off before installing it, but you didn't have to. Even funnier, when you buy the new bearing, compare prices for one with the sensor and one without. Very often, the one with the sensor is a lot less expensive. I suspect that's because they sell so many more of them, the large quantity gets them a better price.

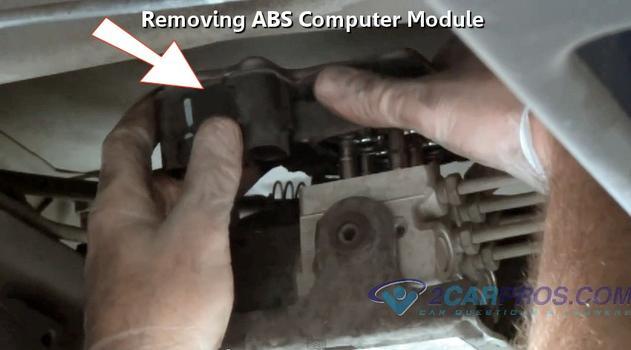

The next problem had to do with how the ABS Computer sets fault codes. In the earlier versions, only one code could be set at a time, at least as far as some problems. Once the missing signal developed, the fault code was set, the warning light turned on, and the computer stopped looking at the other sensors' readings. It could still detect a broken wire, (electrical problem), but it stopped looking at the other three road speeds, (mechanical problem). Since the play in the wheel bearings was so common, there was a real good chance it would happen to the other front one before the first one got taken care of. This was a much bigger problem for owners who ignored the first one for months before deciding to get it repaired. This was also frustrating for mechanics because all they had to go on was the one original fault code. They provided a repair estimate based on that, not realizing the second problem had developed. Once the new bearing was installed and the first fault code erased, the second bearing problem got detected on the next drive cycle. That could be the mechanic on a test-drive or the owner leaving the shop. The owner incorrectly assumed the car wasn't diagnosed correctly or wasn't repaired correctly. The mechanic is frustrated because he has an angry customer to work with, and he has to start all over with the diagnosis.

To my knowledge, this sensor problem didn't involve the rear wheels even though they used the same design.

When you drove around the driveway, you didn't hit 9 mph, so road speeds weren't involved yet. Below that speed, ABS isn't needed or beneficial. Also, since signal strength is reduced at lower speeds, all systems stop responding to prevent "false activation. That's another common GM problem on trucks, also due to weak signals, but the fix doesn't require replacing the sensors, just cleaning them.

Did you erase the first fault code? If you didn't, that can keep the warning light turning on. Next, see what comes up for the next fault code. Let me know what you find.

Saturday, September 30th, 2023 AT 6:20 PM