Smith.P. Sean,

Pleas read this post and let me understand myself better.

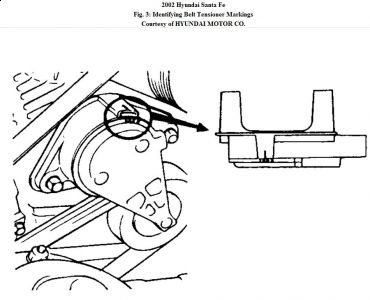

" The illustration posted earlier is no help in identifying how to release the tension "

To me this is confrontaional.

He should have been more tactful.

He should have said that there are two different designs and the diagram did not show the way it is done.

From diagrams we some times do not get the picture corretly so we need to provide extra explanation which is in the post as listed above.

During the course of the post I had already provided additional infornmation.

We work at our spare time to help others and deserve more respect than that. We are not correct all the time and are open to suggestions but the work load at times shortens the fuse.

Tuesday, February 19th, 2019 AT 8:13 PM

(Merged)