Hello Bob

Okay. . ..some info for you. . .. . .. . .. . ...

Let's not rule out the simple. . .. . .. . ..so please check the plug wire resistance.

A bad crank sensor will cause this, a bad ASD, automatic shut down relay. . .. . ..etc. . ..

CRANKSHAFT POSITION SENSOR

1. Disconnect crankshaft position sensor. Connect ohmmeter across sensor terminal No. 2 (Black/Light Blue wire) and terminal No. 1 (Gray/Black wire).

2. Ohmmeter should indicate an open circuit. Replace sensor if reading is not as specified. Also see appropriate crankshaft position sensor tests in TESTS W/CODES - 2.5L article in the ENGINE PERFORMANCE section.

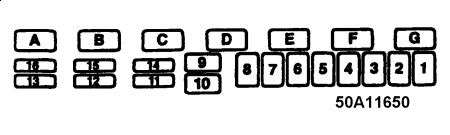

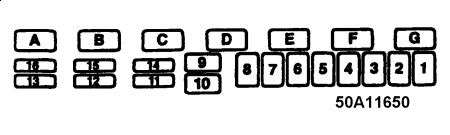

Okay. . ..the odd thing is they don't show a relay panel for 1995. . ...only 1991. . ..they may be the same. In this it state that the ASD relay is "D". I would swap it with another.

Spark Plug & Coil Wire Resistance

Resistance should be 250-1000 ohms per inch.

Do the below test. . ..you will probably only be able to get to step 6 since you don't have a scan tool. But we can see what the other steps show.

1. Attempt to crank engine. If engine will not crank, go to TEST NS-9A . If engine will crank, turn ignition off. Disconnect any one spark plug cable at spark plug. Insert an insulated screwdriver in spark plug cable terminal. Hold screwdriver within 1/4" of ground.

NOTE: When checking for spark, consider one or 2 sparks as a no-spark condition.

2. Crank engine for 10 seconds and watch for ignition spark. If a good spark occurs, go to TEST NS-2A . If a good spark does not occur, turn ignition off. Disconnect coil secondary cable from distributor. Hold coil cable within 1/4" of a good ground. Crank engine for 10 seconds and watch for ignition spark. If there is not a good spark, go to next step. If good spark occurs, repair or replace distributor cap, rotor or spark plug cables as necessary.

3. Turn ignition off. Remove coil cable from coil. Using an external ohmmeter, check resistance of coil cable. Resistance should be 250-1000 ohms per inch. If resistance is more than 15,000 ohms, replace coil cable. If resistance is less than 15,000 ohms, go to next step.

4. Turn ignition off. Remove distributor cap and crank engine. If distributor rotor turns, go to next step. If distributor rotor does not turn, repair distributor drive system as necessary.

5. Install distributor cap and coil cable. Disconnect ignition coil connector and ensure connector is clean and not damaged. If ignition coil connector terminals are okay, go to next step.

6. Turn ignition on. Using scan tool, run ASD fuel system actuation test. While actuating fuel system, put scan tool in voltmeter mode. Check voltage in ASD relay output circuit at coil connector terminal No. 1 (Dark Green/Orange wire). If voltage is more than 10 volts, go to next step. If voltage is less than 10 volts, repair open in ASD relay output circuit.

7. Using scan tool in voltmeter mode, check voltage in ignition coil driver circuit at coil connector terminal No. 2 (Black/Gray wire on Cherokee, Gray wire on Wrangler). If voltage is more than 10 volts, replace ignition coil. If voltage is less than 10 volts, go to next step.

8. Turn ignition off. Disconnect PCM 60-pin connector and ensure connector is clean and not damaged. Using scan tool in ohmmeter mode, check resistance in ignition coil driver circuit at PCM 60-pin connector terminal No. 19 (Black/Gray wire on Cherokee, Gray wire on Wrangler). If resistance is more than 5 ohms, go to next step. If resistance is less than 5 ohms, repair short to ground in ignition coil driver circuit.

9. Using an external ohmmeter, check resistance in ignition coil driver circuit between ignition coil connector terminal No. 2 (Black/Gray wire on Cherokee, Gray wire on Wrangler) and PCM connector terminal No. 19. If resistance is more than 5 ohms, repair open in ignition coil driver circuit between ignition coil connector and PCM 60-pin connector. If resistance is less than 5 ohms, replace PCM.

Since you have a 1995 some can use a scan tool and some not. I am going to go with not first. Try reading codes by doing the below. Then let me know what the code is.

MIL Diagnostic Mode

1. Start engine (if possible). Move transmission shift lever through all positions, ending in Park. Turn A/C switch on and then off (if equipped).

2. Turn engine off. Without starting engine again, turn ignition on, off, on, off and on within 3 seconds. Record 2-digit DTCs as displayed by flashing MIL.

3. For example, DTC 23 is displayed as flash, flash, 4-second pause, flash, flash, flash. After a slightly longer pause, other codes stored are displayed in numerical order. When MIL begins to flash DTCs, it cannot be stopped. Start over if count is lost. Code 55 indicates end of fault code display.

4. Refer to DIAGNOSTIC TROUBLE CODES/MESSAGES to translate trouble code number to a scan tool fault message. Once trouble area is identified, refer to TEST TC-1A in TESTS W/CODES article in this section. DTCs indicate results of a failure, but do not identify failed component(s) directly. Use scan tool fault messages to find appropriate test.

5. As an example, a 2.5L engine starts and runs but has a driveability problem. MIL indicates DTC 14. Refer to DIAGNOSTIC TROUBLE CODES/MESSAGES to translate trouble code number to scan tool fault message. When scan tool fault message is obtained, refer to appropriate test number in TESTS W/CODES article. To clear DTCs, see CLEARING DIAGNOSTIC TROUBLE CODES .

Okay. . .. . .. . ...let me know what you find out. . .. . .. . .

Saturday, September 26th, 2020 AT 12:35 PM

(Merged)