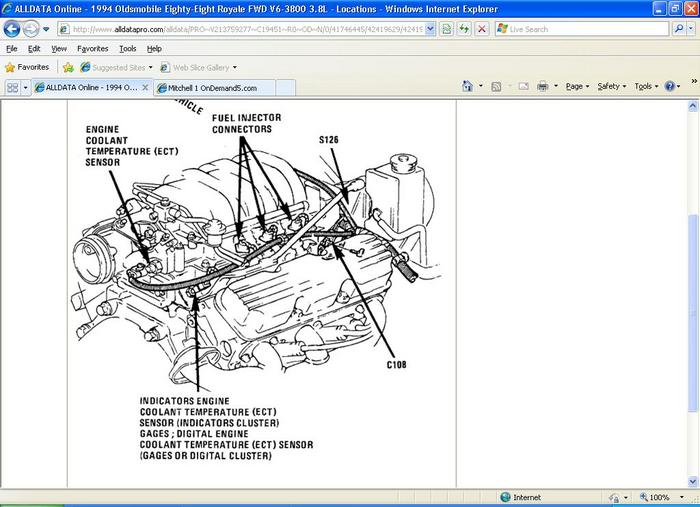

I would agree you have a bad coolant temp sensor or the wire going from the computer to the sensor or the connector itself. There are two sensors one for the gauge and one the computer.I posted a trouble tree for the code's which includes how you can test the sensor with a multimeter. Also see below the code description I posted.I also posted a wire diagram and which sensor is which and where there located. Let me know what you find.

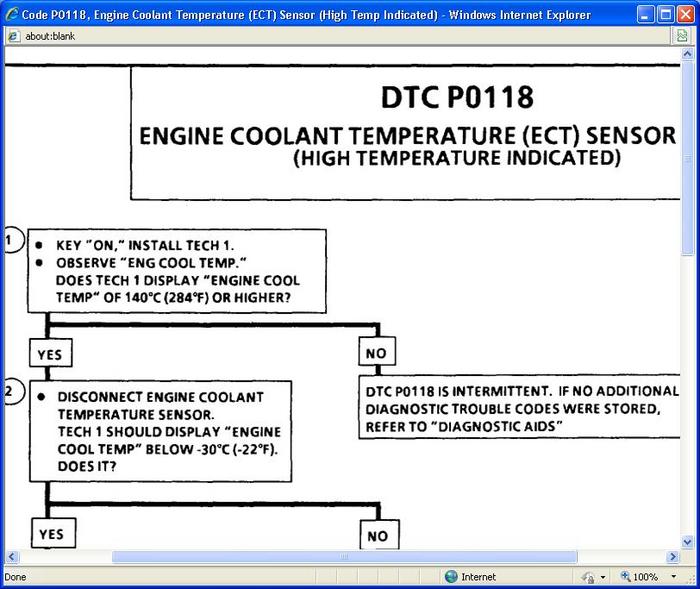

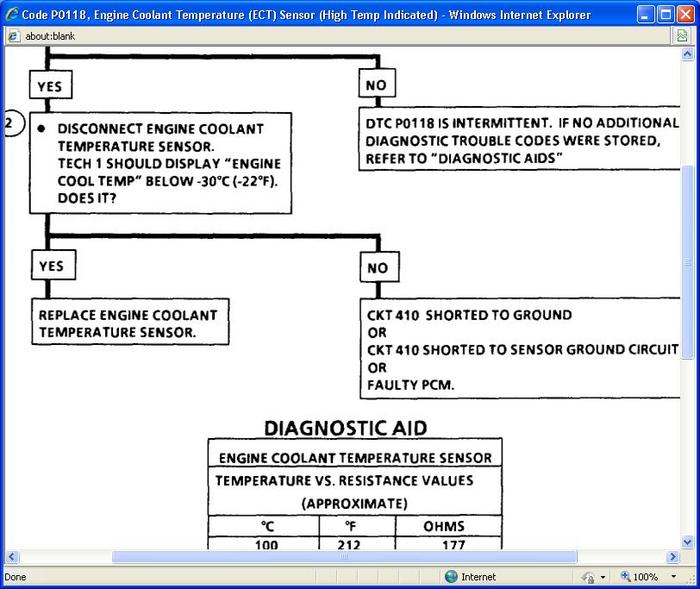

Code P0118, Engine Coolant Temperature (ECT) Sensor (High Temp Indicated)

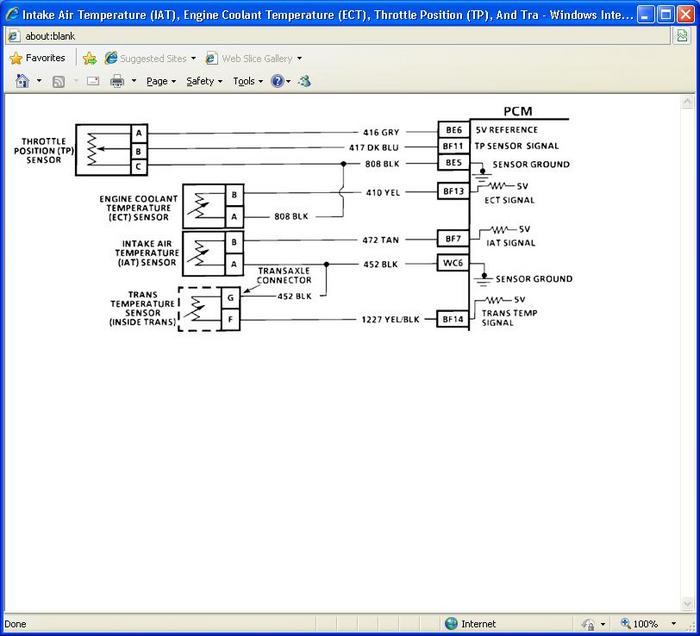

Intake Air Temperature (IAT), Engine Coolant Temperature (ECT), Throttle Position (TP), And Trans Temperature Sensors Wiring Schematic

CIRCUIT DESCRIPTION

The Engine Coolant Temperature (ECT) sensor uses a thermistor to vary the signal voltage from the PCM. The PCM applies a voltage on CKT 410 to the sensor. When the engine is cold the sensor (thermistor) resistance is high; therefore, the PCM will see high signal voltage. As the engine warms, the sensor resistance becomes less and the voltage drops. At normal engine operating temperature (85°C to 95°C), the ECT signal will measure about 1.5 to 2.0 volts.

DTC P0118 WILL SET WHEN:

Engine run time is greater than 15 seconds.

Signal voltage indicates engine coolant temperature above 140°C (284°F) for.4 second.

ACTION TAKEN (PCM will default to):

With a current DTC P0118 set, the PCM will turn the high speed cooling fans "ON" and use a default engine coolant temperature value based on run time. The default value will rise to a maximum value of 90°C (194°F). The PCM will illuminate the MIL (Service Engine Soon).

TEST DESCRIPTION

Number(s) below refer to circled number(s) on the diagnostic chart.

Determines if conditions necessary to set DTC P0118 exist.

This test will determine if CKT 410 is shorted to ground which will cause the conditions for DTC PO118.

DIAGNOSTIC AIDS

Tech 1 displays engine coolant temperature in degrees. After engine is started, the temperature should rise steadily to about 90°C (194°F) then stabilize when thermostat opens.

An intermittent may be caused by rubbed through wire insulation.

Check for:

CKT 410 for a short to ground.

Intermittent test - With Tech 1, monitor engine coolant temperature while moving related connectors and wiring harness. If the failure is induced, the "engine coolant temperature" display will change. This may help to isolate the location of the malfunction.

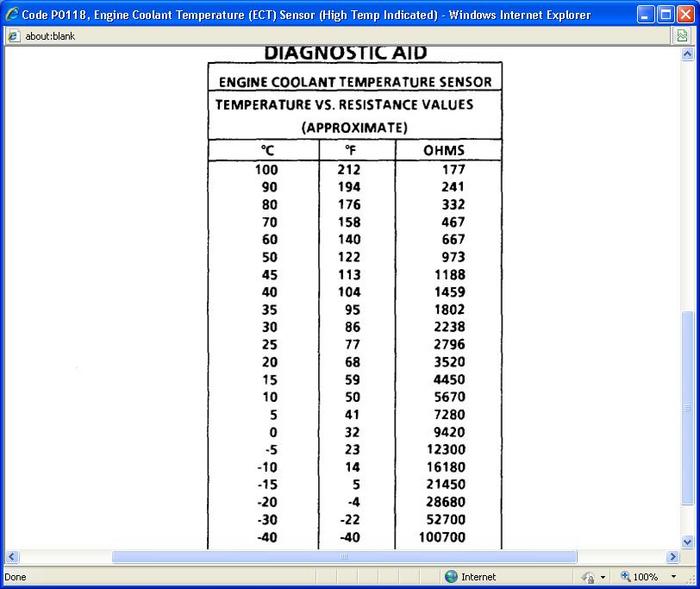

Shifted sensor - The "Temperature To Resistance Value" scale may be used to test the engine coolant temperature sensor at various temperature levels to evaluate the possibility of a "shifted" (mis-scaled) sensor, which may result in driveability complaints.

Images (Click to make bigger)

Monday, April 11th, 2011 AT 8:51 PM