Code 624c = EPC circuit failure.

CKT TEST TG - ELECT TRANS CONTINUOUS MEM DIAG TROUBLE CODES

Diagnostic Aids

Perform this test only when directed by QUICK TEST. To prevent replacing good components, be aware the following non-EEC areas may be at fault:

� Transmission fluid level.

� Engine/transmission fluid temperature.

� Ambient temperature.

� Faulty wiring harness connectors.

This test is intended to diagnose:

� Wiring harness circuits CCS, SS1, SS2, SS3, EPC, TCC, TFT, and MLP.

� Powertrain Control Module (PCM)

NOTE:

Procedure begins with step 90). No test procedures have been omitted.

90)Perform Drive Cycle Test Ensure all components are connected. Ensure transmission fluid is correct level. Warm engine to normal operating temperature. Perform KOEO and CONTINUOUS MEMORY CODE SELF-TEST. Clear all codes. Perform appropriate DRIVE CYCLE TEST.

Drive Cycle Test (AX4S)

With transmission gear selector in Overdrive position, moderately accelerate vehicle to 50 MPH for at least 15 seconds. Transmission should be in 4th gear. While holding speed steady, lightly apply and release brake for about 5 seconds. Stop and park vehicle for a minimum of 20 seconds with transmission gear selector in Drive position. Repeat procedure 5 times. After completing drive cycle test, perform KOEO and CONTINUOUS MEMORY CODE SELF-TEST. If Code 111 is present, fault cannot be duplicated at this time. If Code 624, 634 or 651 is present, go to step 91).

91)Code 624, 634 Or 651. Code 624 and 651 indicate Electronic Pressure Control (EPC) failure. Code 634 indicates that Manual Lever Position (MLP) sensor is out of calibration. Possible causes for these faults are:

� Faulty EPC solenoid.

� Faulty MLP sensor.

� Circuit open or grounded.

� Damaged PCM connector pins.

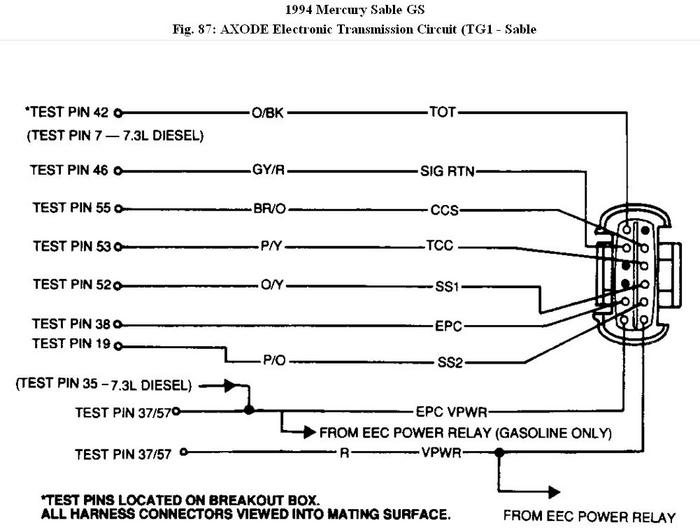

Turn ignition off. Disconnect 60-pin PCM connector. Inspect connector for damaged pins, corrosion and loose wires. Repair as necessary. Install EEC-IV Breakout Box (T83L-50-EEC-IV). Connect PCM to breakout box. To test EPC solenoid, connect DVOM to EPC test pin and EPC VPWR test pin at breakout box. To test MLP sensor, connect DVOM to MLP test pin and test pin No. 46 at breakout box. For EPC solenoid and MLP sensor, turn ignition on. Voltage for EPC should be less than 10 volts. Voltage for MLP should be less than 5 volts. Shake and bend EPC/MLP wiring harness. Lightly tap on components to simulate road shock. Voltage should remain stable. If voltage changes or exceeds specification, fault in circuit is indicated. If fault is indicated, isolate and repair as necessary. Clear continuous memory codes, and repeat QUICK TEST. If no faults are found, problem cannot be located at this time.

92)Check Circuit Harness & Connectors. Enter CONTINUOUS MONITOR MODE. Shake and bend EEC wiring harness while observing analog VOM or scan tool. Lightly tap on components to simulate road shock. If VOM indicator has erratic movement or scan tool beep, fault is indicated.

If fault is indicated, isolate and repair as necessary. Clear continuous memory codes, and repeat QUICK TEST. If no faults are found, problem cannot be located at this time.

Image (Click to make bigger)

Friday, November 19th, 2010 AT 3:28 PM