Common Misconception: When an engine misfires, the cylinder runs lean, not rich, this is because the air to fuel ratio favors air by 14x. Therefore, an engine must be running properly without cylinder misfires to avoid lean mixture codes. Optimum air to fuel mixture (14 to 1) is called stoichiometric, which means: chemically balanced. The engine fuel management system is controlled by the computer and various sensors which feedback data. After repairs are completed, clear the trouble codes and allow the computer monitors to reset by driving between 20 and 40 miles to confirm correct system functionality.

Best Practices

- Check all vacuum hoses when replacing a single failed hose.

- Check connecting hoses to such items as a breather tube or EVAP system

Let's Jump In!

Once a

check engine or service engine soon light has determined a lean engine code

has materialized, a repair procedure inspection is needed. Explanation: A lean code

is enabled when the computer has detected enrichment adjustments have maxed out,

with no results, this inability triggers the lean code.

Un-metered air which enters the intake system of the engine can cause a lean

mixture code to be triggered, inspect all vacuum lines for cracks or dilapidation.

Check the integrity of vacuum hoses at each end of the hose.

The intake system utilizes gaskets which seal various components, if these gaskets

fail a vacuum leak will

result, causing the code failure. Use carburetor cleaner to help locate any potential

leaks by spraying around gasket surfaces and observe a rise in engine idle speed

if a leak exists.

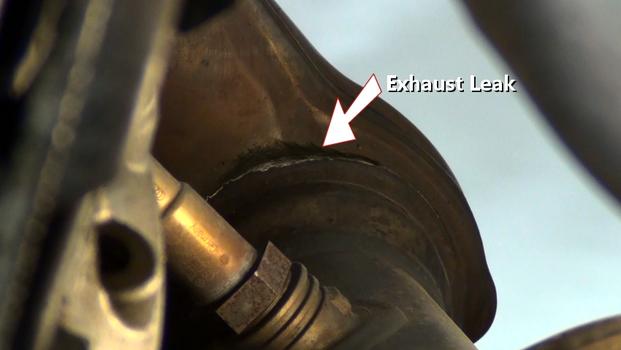

An exhaust leak will allow fresh air to enter the system on the negative pressure

side of an exhaust event, this will cause an

oxygen sensor to

produce a lean reading. An exhaust system manages both pressure and vacuum cycles

while an engine runs. To inspect for an exhaust leak, have a helper start the engine

and hold the idle at about 1500 rpm, listen for additional exhaust noises coming

from the system including manifolds

and head pipes. Also, look for black soot at any point in the system as this

can indicate an exhaust leak.

After miles of driving, the mass air flow sensor's filament or hot wire, can

become contaminated due air impurities which create false readings. Using sensor

safe carburetor cleaner to clean this filament can sometimes remove these deposits

allowing the sensor to obtain a correct reading.

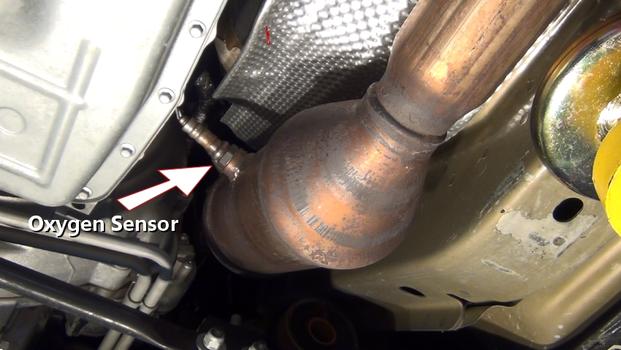

Testing the exhaust system

oxygen sensors can

help determine the functionality of the sensor. If the sensing element fails, feedback

information will be incorrect causing a lean mixture code.

When an engine misfires an almost clean charge of oxygen is released into the

exhaust system. This will cause the exhaust system to test lean as tested by the

O2 sensors, this can sometimes be fixed by a

tune up.

An air intake boot transfers engine air from the mass air flow sensor to the

throttle actuator. If the boot

fails, it can cause a false reading from the mass air flow sensor producing the

code.

Questions?

Our certified technicians are ready to answer lean exhaust questions for free. We hope you saved money and learned from this guide. We are creating a full set of car repair guides. Please subscribe to our 2CarPros YouTube channel and check back often for new videos which are uploaded regularly.