A camshaft is a cylindrical rod that is situated in the cylinder block or head which has oblong lobes or cams which push intake and exhaust valves open, all internal combustion engines have at least one camshaft, even hybrid cars. There are two popular styles of camshaft systems which are called overhead cam (OHC), and in block camshaft configurations. An overhead camshaft set up has the ability to offer two camshafts (DOHC) which is able to accompany twice as many valves for both intake and exhaust.

Because the combustion process is not perfect the opening of the exhaust valve and intake valve will intersect slightly. While one is closing the other is opening which is called valve overlap. Performance camshafts have increased valve lift, duration and overlap causing the exhaust gases mix with the intake charge of the cylinder which is why engine that have these camshafts have a rough idle.

1. Overhead Camshafts

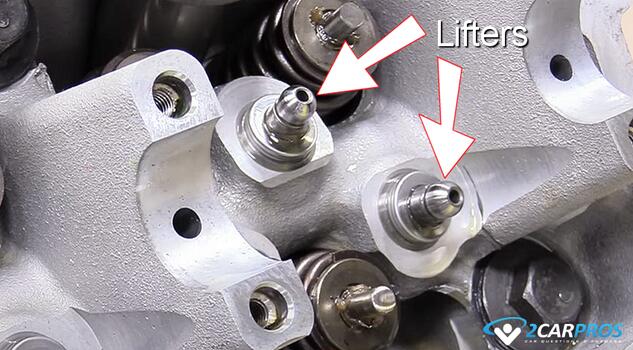

By far the most popular design is the over head camshaft because of its simplicity. Overhead camshaft designs include a lifter that is located in the cylinder head and is used to automatically adjust the valve lash (clearance). This lifter provides the adjustment between the camshaft and valve which allows the valve to fully close without excess clearance. The lifter galley oil passage is designed into the cylinder head to supply oil pressure provided by the engine's oil pump via the block's internal oil galleys which is used to lubricate the lifter as well as help it control valve lash (clearance).

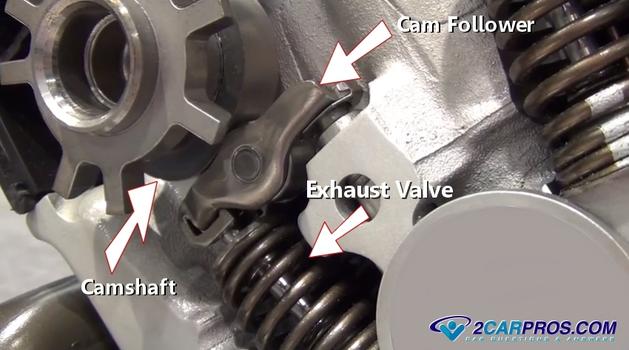

The picture below shows the roller which is situated in the middle of the rocker arm providing a more efficient way if transferring the camshaft's lift to the rocker with little friction. It also allows a more aggressive camshaft lobe profile which helps engine performance.

Here we show an overhead cam set up with the cylinder head and block cutaway, the lifters are directly over the valve spring with four valves per cylinder, two intake and two exhaust. On four valve set ups, the valves are slightly smaller in size but may allow more air flow than one larger valve.

As the camshaft rotates the lobe which protrudes from the centerline forces the cam follower downward which in turn opens the valve. The rocker is equipped with a needle bearing roller to reduce friction and help the engine's performance. This style of rocker arm is also known as a cam follower.

2. Camshaft in Block

In some engine designs the camshaft is located inside the engine block. Because the camshaft is further away from the intake and exhaust valves a different configuration of the rocker arm and lifter is used. The lifter now rides along the camshaft with the lobe cut at a slight angle at the top of the lobe which help spin the lifter slightly to help stop wear.

A long steel pushrod is used between the lifter and rocker arm to work the valve. This design is traditionally less efficient than its overhead counterpart due to the added weight of the additional component which requires a valve spring with more tension to close the valve. In this style of camshaft set up several different lifters are used, the traditional hydraulic, roller, mushroom and solid, (must be manually adjusted).

Solid lifters are used mostly in racing applications where higher engine rpm for long periods of time can damage normal hydraulic lifters. The picture below shows the camshaft inside the block (bottom).

In this configuration the lifter rides inside a lifter bore which is located in the engine block itself. Roller lifters are exactly as the name implies, they are designed with a roller wheel and needle bearings that ride along the camshaft which reduces drag. A lifter can also be called a tappet, this picture shows the lifter being removed from the top side of the engine block.

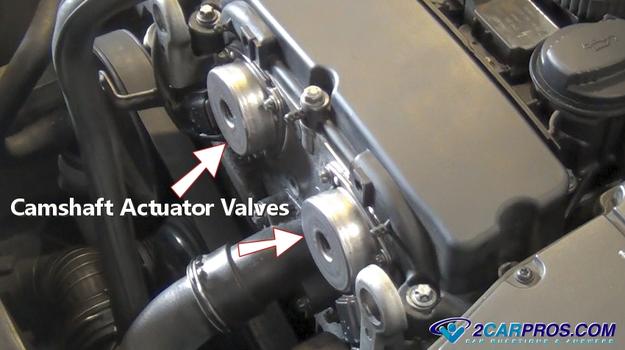

3. Variable Valve Timing Camshafts

Modern engines often use variable valve timing (VVT) systems to adjust the camshaft's position relative to the crankshaft. This adjustment improves engine efficiency, power, and emissions by optimizing valve timing for different operating conditions. More information: Variable Camshaft Timing

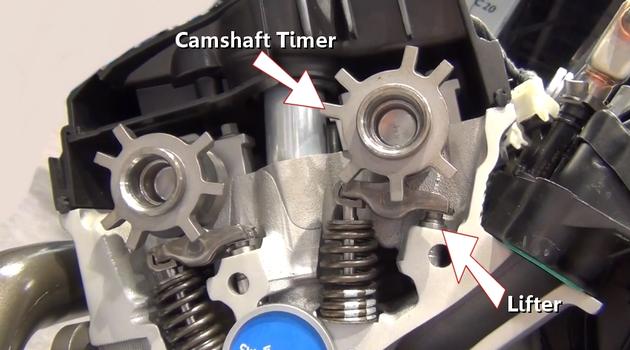

4. Camshaft Position Sensor and Timer

A camshaft features a timer that is used with the camshaft angle sensor which sends feed back information to the car's computer to process and make adjustment in the engine's operating program. This is what a typical timer looks like:

The camshaft position sensor can be located at the front or rear of the camshaft in most cases. These are simple two wire sensors, here is what they look like in the image below.

5. Camshaft to Crankshaft Relationship

The camshaft turns at a rate of 1 to 2, in other words the crankshaft of the engine turns twice for every one turn of the camshaft. The camshaft is connected to the crankshaft by a timing chain or timing belt.

6. Performance Camshafts

The camshaft is responsible for converting rotational motion into linear motion and can be designed in such a way that will affect the engine performance characteristics and emission outputs. The distance the valve opens downward in the cylinder head is called lift while the amount of time the valve is open is called duration. This increases engine top end horse power due to the increased air flow.

7. What Goes Wrong?

- The number one reason a camshaft will fail is dirty oil, due to the lack of oil changes. This will cause the camshaft lobes to wear down causing an engine misfire and low power output.

- Lack of oil pressure or when the is low on oil, which will cause clicking or clattering sounds. As the rocker arm is forced away from the camshaft, the oil valve inside the lifter closes which traps the oil inside the lifter making it solid while opening the valve.

Watch the Video!

Please watch this video of the job being done to glean additional helpful information.

Credits

This guide knowledge base was created by the 2CarPros Team, and by Ken Lavacot: Automobile repair shop owner and certified master automobile technician of over 30 years. If you have question or need help please ask one of our experts we are happy to help. Please visit our 2CarPros YouTube Channel for additional car repairs.