Hi and thanks for using 2carpros.com

It sounds like the fuel pump failed. Here is a link that shows in general how to check for fuel pressure. However, your vehicle has a throttle body and not injection, so you will have to open the fuel system and insert a T in it so pressure can be tested.

https://www.2carpros.com/articles/how-to-check-fuel-system-pressure-and-regulator

Here are the directions for replacing the pump. All attached pictures correlate with these directions. Note: The fuel tank needs removed to access the pump. Often times, the strap bolts are rusted and break. As a result, and this is how I do theses, there are 8 bolts that hold the bed on to the frame. I found it is easier to remove the bolts, disconnect the rear tail lights and remove the bed or safely prop the driver's side up so I can access the pump.

_______

FUEL PUMP/FUEL GAUGE SENDING UNIT REPLACEMENT

REMOVAL:

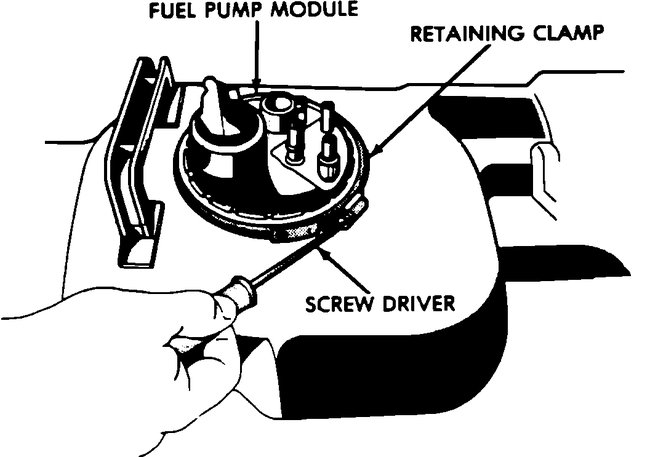

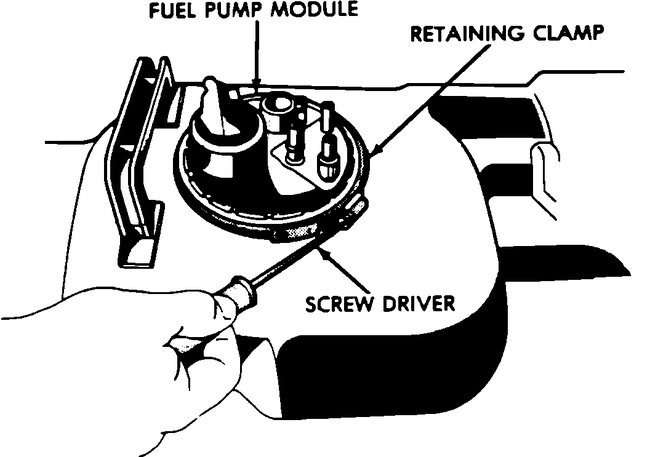

Fuel Pump Module Removal/Installation

1. Fuel system pressure must be released prior to service.

2. Fuel tank must be removed prior to fuel pump service.

3. While holding the fuel pump module down, remove the retaining clamp. After the clamp is removed release the fuel pump module and it will spring up from the fuel tank.

4. Remove the fuel pump module from the fuel tank.

DISASSEMBLY

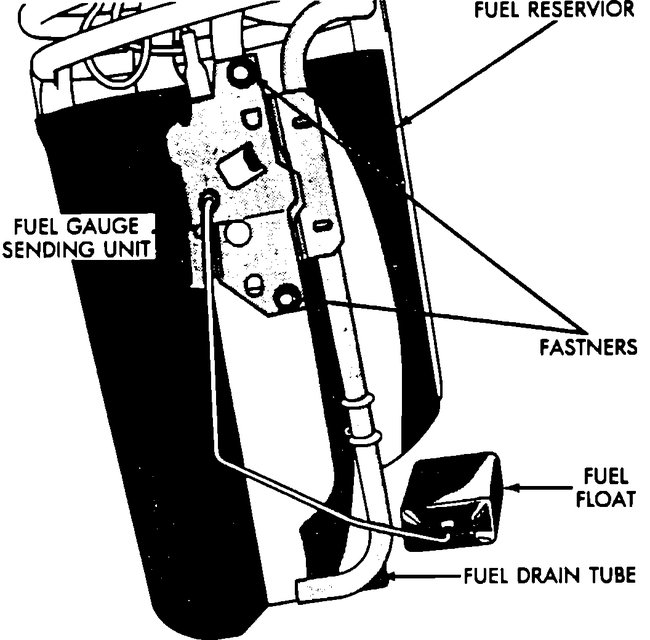

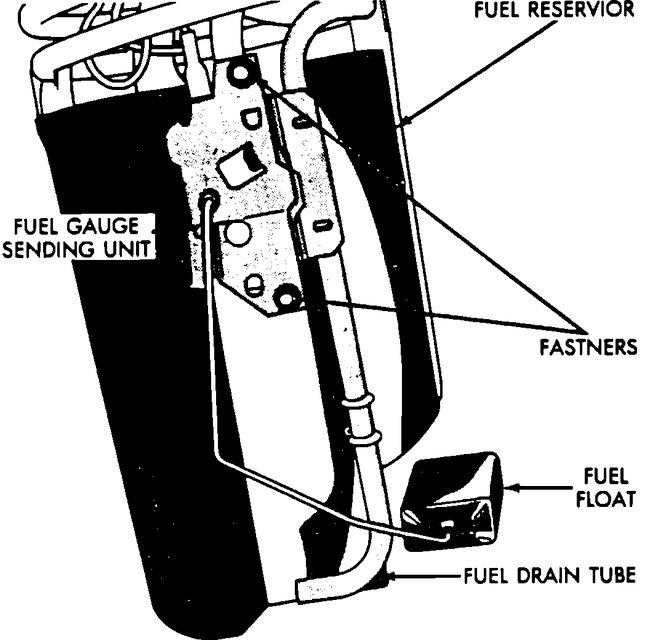

Fuel Gauge Sending Unit Service

1. Remove sending unit attaching screws from mounting bracket located on the side of the fuel pump reservoir.

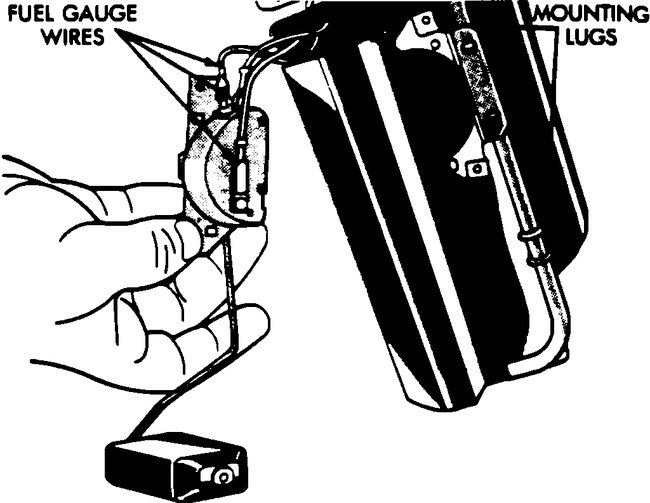

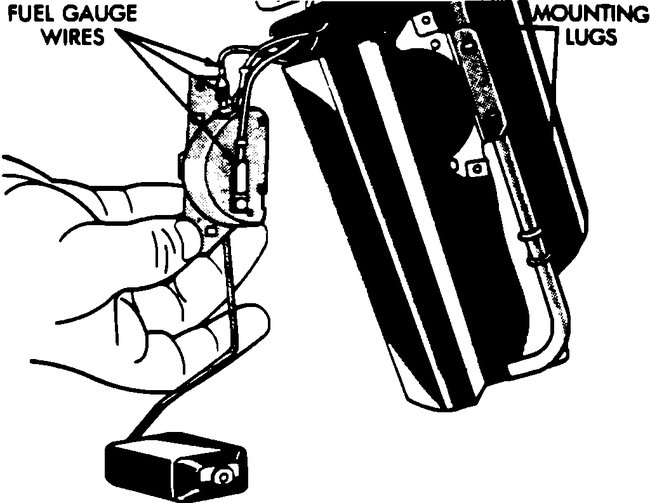

Fuel Gauge Sending Unit Wiring Terminals

2. Disconnect electrical connections from sending unit, and remove sending unit.

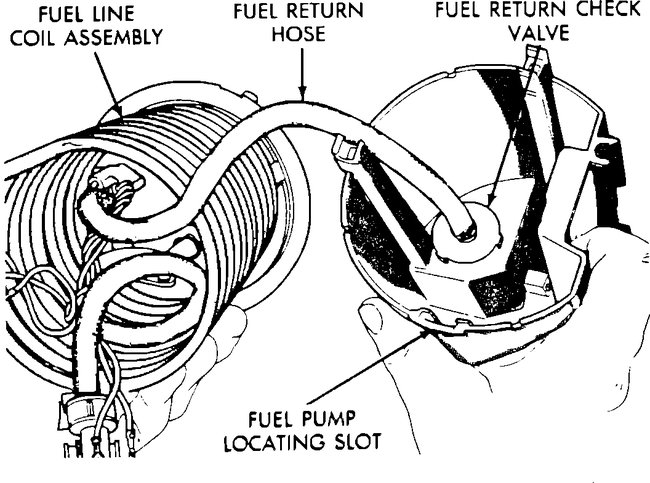

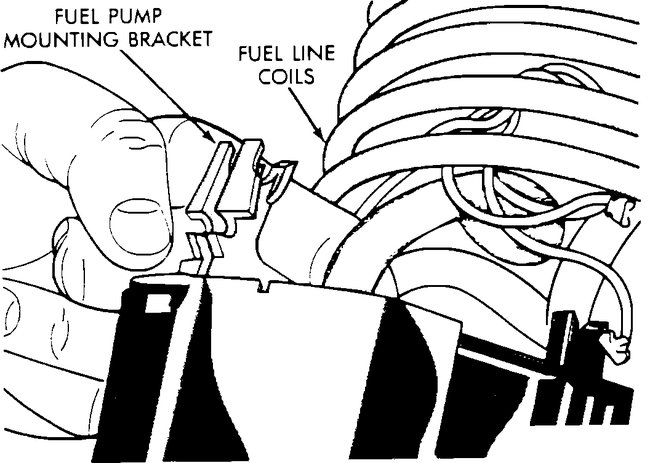

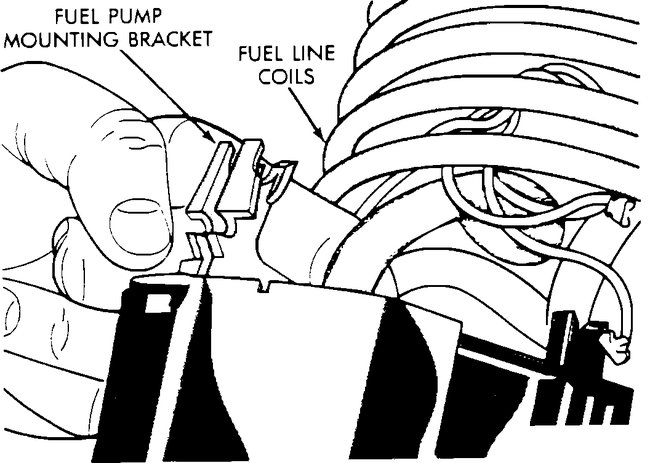

Removing Fuel Line Coil From Reservoir

Fuel Pump And Reservoir Assembly

3. Remove drain tube from the side of the fuel reservoir. Be careful not to let the fuel return line and check valve come detached from the inside of the reservoir.

Fuel Pump Mount Bracket

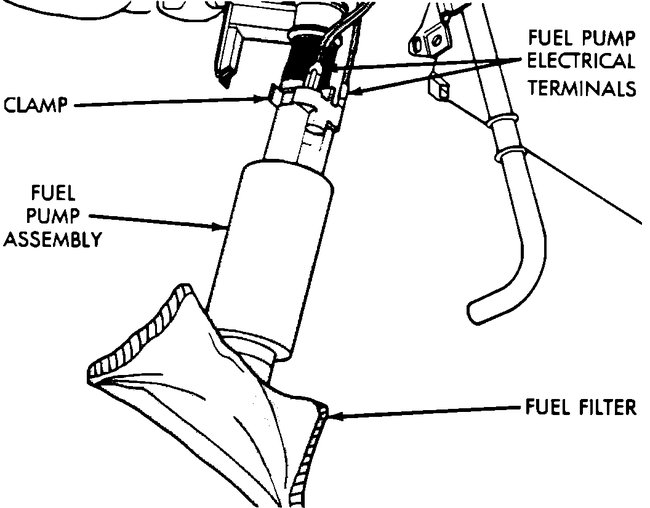

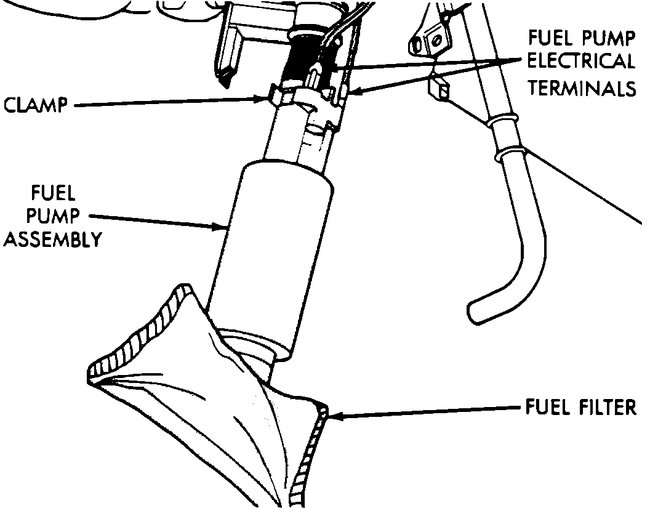

Fuel Pump Removal/Installation

4. Remove the fuel pump assembly by pressing on the mounting bracket with your thumb and forefinger. Press with both thumbs toward the center of the fuel reservoir.

Servicing In-Tank Fuel Filter

5. Remove pump mounting bracket and rubber collar from hose and retain for assembly. Cut the hose clamp from the supply hose and discard. Remove pump/strainer assembly from hose.

Servicing In-Tank Fuel Filter

6. If fuel pump is functioning properly but fuel strainer is defective, use a broad blade screwdriver and "walk" around the strainer mounting ferrule to remove it from the fuel pump. Be careful not to damage the fuel pump inlet. If fuel pump is defective, replace both the pump and filter.

ASSEMBLY

1. Press new strainer onto pump (new pumps come with a new strainer).

2. Install new clamp to attach the fuel pump to the supply hose. Use tool # C-4124, or equivalent, to crimp clamp.

Servicing In-Tank Fuel Filter

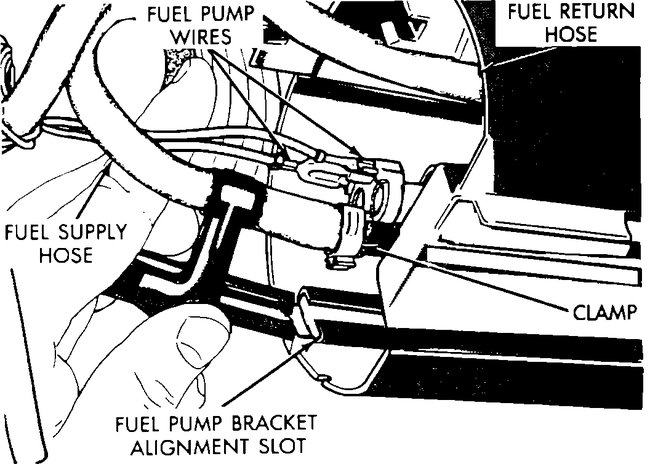

3. Reposition pump mounting bracket and rubber collar on the fuel supply hose between the bulge in the hose and the fuel pump.

4. Install the fuel pump inside the fuel reservoir so that the fuel strainer aligns with the cavity in the reservoir.

Fuel Pump Mount Bracket

5. Snap fuel pump bracket into the reservoir.

6. Install the reservoir so that the drain tube aligns with the mounting lugs on the reservoir.

7. Snap the lower-most fuel coil into mounting lugs in the top of the reservoir.

8. Snap the drain tube into the lugs on the bottom of the reservoir.

Fuel Gauge Sending Unit Wiring Terminals

9. Connect the electrical wires to the fuel gauge sending unit.

10. Align the index hole on the reservoir with the index tab of the new sending unit mounting bracket.

Fuel Gauge Sending Unit Service

11. Attach sending unit to mounting bracket and tighten the mounting screws.

INSTALLATION

1. Wipe seal area of tank clean, and install a new O-ring seal on pump.

Fuel Pump Module Retaining Bracket

2. Align fuel pump module with fuel pump mounting bracket (in the bottom of the fuel tank).

Fuel Pump Module Removal/Installation

3. Push fuel pump module into the retaining bracket and hold with one hand while tightening the clamp with the other hand. Tighten the clamp to 40 lb-in (4.5 Nm)

4. Install fuel tank assembly.

5. Perform fuel system pressure test to check for leaks.

Let me know what you find or if you have other questions.

Take care,

Joe

Images (Click to make bigger)

Thursday, January 3rd, 2019 AT 5:22 PM