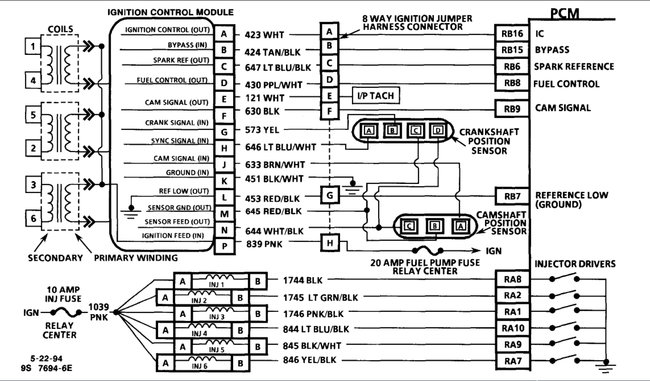

You would need a scan tool that will communicate with the system to see if you have a crank signal to the ECM.

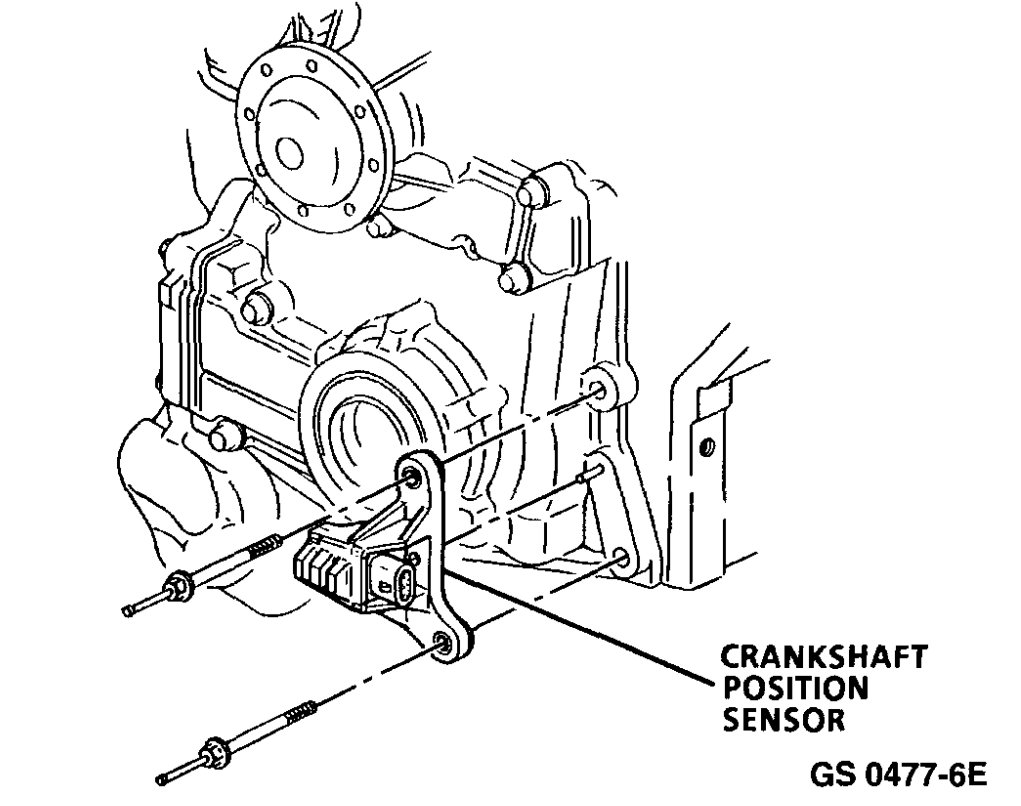

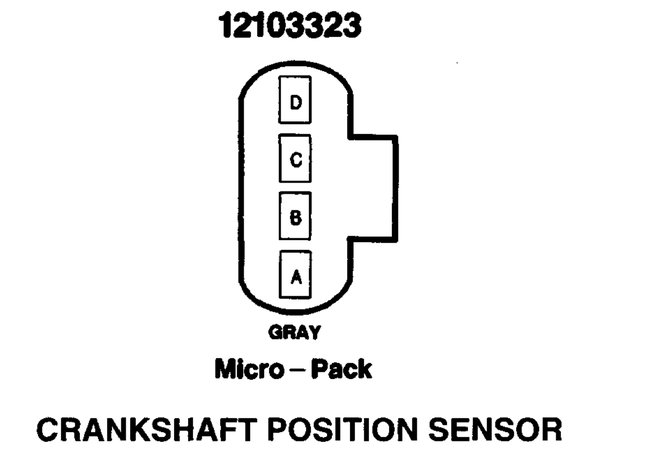

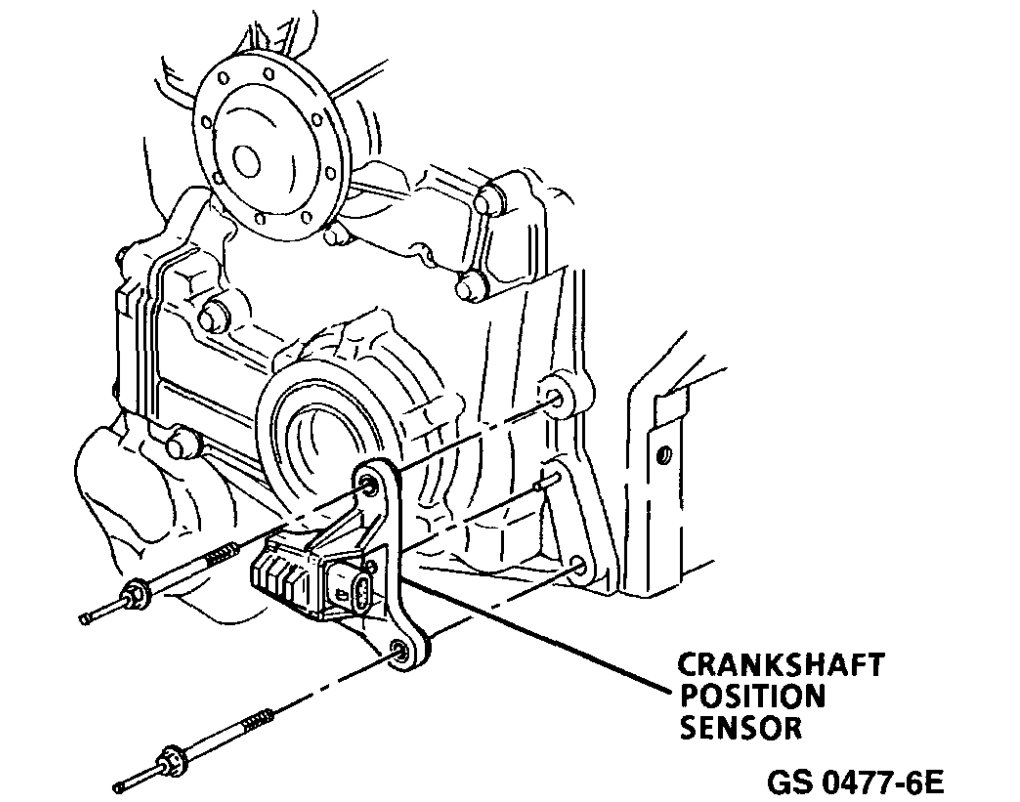

I attached the diagram of the sensor as well as the location and a picture for you.

https://www.2carpros.com/articles/how-to-check-wiring

Roy

REMOVE OR DISCONNECT

1. Negative battery cable.

2. Serpentine belts from crankshaft pulley.

3. Raise vehicle.

4. Right front tire and wheel assembly.

5. Right inner fender access cover.

6. Using 28 mm socket, remove crankshaft harmonic balancer retaining bolt.

7. Crankshaft harmonic balancer using special tool (J 38197).

8. Crankshaft position sensor shield.

9. Sensor electrical connector.

10. Sensor from block face.

INSTALL OR CONNECT

1. Crankshaft position sensor to block.

2. Bolts to hold sensor to block face.

Tighten to 20-40 Nm (14-28 lb. ft).

3. Crankshaft position sensor shield.

4. Electrical Connector.

5. Balancer on crankshaft.

6. Apply thread sealer to threads of crankshaft balancer bolt.

Tighten bolt to 150 Nm + 76° (110 lb ft + 76°).

7. Inner fender shield.

8. Tire and wheel assembly.

Tighten lug nuts to 140 Nm (104 lb. ft).

9. Lower vehicle.

10. Serpentine belt.

11. Negative battery cable.

Images (Click to make bigger)

Monday, March 15th, 2021 AT 2:50 AM