Oops; I overlooked your first reply. I can't find any reference to a 320i. Is your car a rear-wheel-drive model? If it is, I would expect to see "caster" listed and adjustable.

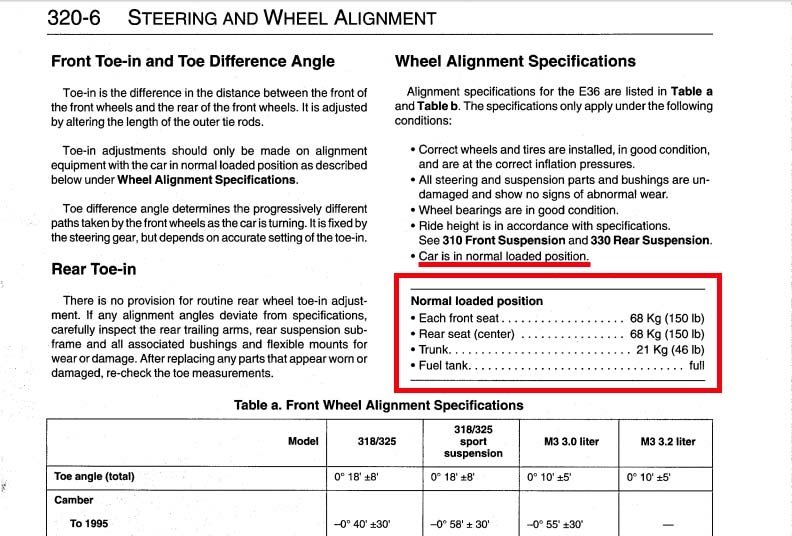

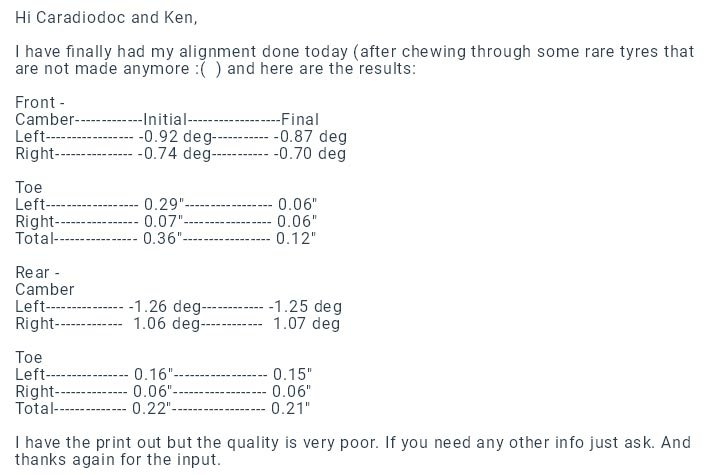

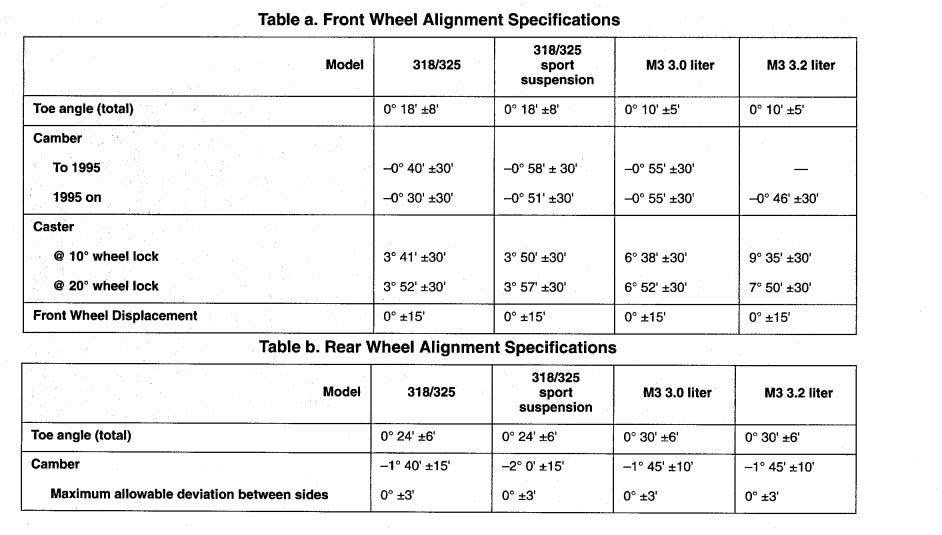

The negative camber readings mean both front wheels are tipped in on top, quite a bit. The tires will be running on the inner edges when driving straight ahead. This is one of those compromises I mentioned a while ago. When you corner at high speed, one corner of the car will be pushed down, and the resulting changes in the geometric relationship of the suspension parts is expected to move the top of that wheel outward. With more normal camber settings, that would cause the tire to be tipped out on top and running on the outer edge. By starting with the negative camber, that change during high-speed cornering will put the tire closer to straight up and down, so more tread contacts the road surface. This is where you get the better cornering ability but you lose the tire wear when driving straight ahead. Ford is famous for a similar compromise between tire wear and comfort. On some of their front-wheel-drive cars, a pair of tires will only last 15,000 miles if you're lucky, but those cars are much more comfortable than similar competitors' models. You won't know about the tire wear problem when test-driving and comparing models when deciding which one to purchase, but you will notice the difference in comfort.

It is possible no change was made to the front camber adjustments. The few hundredths of a degree difference in the "Before" and "After" readings would be extremely difficult to adjust in. That's like trying to use an ax to split a hair. What is more likely is the springs settled a little from the car being tugged and poked. A little speck of dirt in the turntables could bind one of the marbles it rolls on, then by just touching the door handle, that plate could move a tiny fraction of an inch and let that wheel settle to a different position. Even opening the driver's door a couple of inches will change those camber readings that few hundredths of a degree. These projectors are extremely sensitive. Where we could measure to the eighth of a degree with the old mechanical equipment, and that was good enough for those cars, the computers let us get down to the hundredth of a degree, which has the potential to be too nit-picky. Your mechanic has his computer set up to read two places after the decimal point, like I did. That gets you much more precision, but just breathing on the car can change the readings that much.

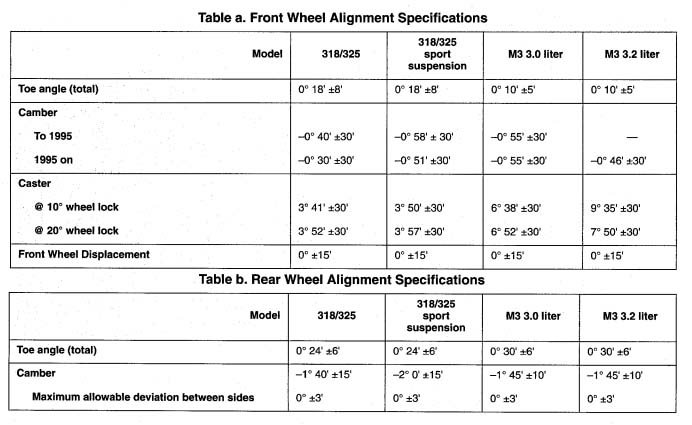

Rear camber is also very high negative. I cringe when I see tires tipped in that much, but until I know what the factory specs are, I'll wait with comments about tire wear issues.

The first of the last adjustments is rear toe. Front toe is done last because we need to match the wheels' direction if steering to the that of the rear wheels, and first, the rear wheels have to be adjusted as close as possible to perfectly parallel to the car. Only the "total toe" on one axle affects tire wear on those two tires. Both wheels can be badly misadjusted, but if they're both off the same direction, the total of their two readings can still be good and provide good tire wear. This would be an example of where the rear is steering off to one side, but if we adjust the front wheels to be parallel to those rear wheels, the steering wheel will still be straight. A lot of cars today have threaded links for adjusting rear toe. Those let us dial them in to the perfect adjustment. When both rear toe values are identical, as a pair, they do not steer the rear of the car off-center to either side. That would be 0.00 degrees "thrust angle". On older models, particularly Chrysler and GM front-wheel-drive models, rear toe was adjusted by unbolting the wheel bearing and sticking in a tapered shim to turn that bearing a little. There could be a dozen different shim thicknesses to pick from, but we had to pick the one that got it the closest to perfect as possible. Those usually offered us a choice of "better than it was", "even closer to perfect", "still better", or "too much". It was very rare to hit both rear toe settings perfect, but it was only the "total toe" that had to be close enough to prevent tire wear.

It looks like your rear toe also didn't need to be adjusted. If 0.21" is in specs for total toe, I also would leave it alone. That's close to a quarter inch, which in my mind is a lot, but I'll come back to that later. Being a positive number, it means the fronts of the wheels are a little closer together than the rears of the wheels. Toe-in is specified when road forces are expected to pull the wheels back a little while driving and braking. Toe-out is rarely specified for the rear. When it is, it is usually because it is expected to compensate for some change that takes place during hard acceleration or some other condition that is frequently encountered. One of those conditions could be the geometric changes the suspension parts go through under various driving conditions.

Your two rear individual toe readings are not equal, but their difference is much too little to discuss. The left rear wheel is turned toward the center of the car by 0.10 degrees more than the right one. If everything else was not a variable, that difference might equate to your steering wheel being turned to the right by half an inch. Over all, the rear axle is steering that end of the car off to the right just a fuzz. That would make the car turn slightly to the left, and you compensate for that by turning the steering wheel slightly to the right. Once you do that, all four wheels are parallel to each other.

Once rear total toe is close enough, the very last step is to adjust front toe to make total toe perfect for best tire wear, and to match each wheel to the rear wheels so the steering wheel will be straight. If steering parts were replaced, we may need to rough-in some of these adjustment first before we let the computer take the "Before" readings, but unlike your hand tools you started out using, when we adjust front left toe, even though that projector is turning with the wheel, it doesn't affect the rear toe reading, even though the rear projector is using the front one for a reference. Much older mechanical alignment equipment used mirrors and light beams, so if you adjusted the wheel with a mirror, the other wheel's reflected beam incorrectly showed a change had been made too. There was a lot of manual calculations we had to make with that equipment. That isn't an issue with the computerized equipment. So, regardless if anything was changed related to rear toe, it's the front toe that needed some attention. All of the toe readings can also be displayed in degrees, but you have it shown in decimal inches. That is also how I set up my computers. The 0.12" total toe you ended up with on the front is perfect for a lot of car models, especially rear-wheel-drive models. That is very close to 1/8th inch, wheels are closer together at their fronts than at their backs. Both front wheels are steering very slightly toward the center of the car. Road forces and braking forces will tug the tires and wheels back a little, making them perfectly parallel to each other while driving.

You started with 0.36" total toe on the front, most of that on the left wheel. That's three times what you should have. To visualize how that affects tire wear, it helps to exaggerate it for clarity. Imagine if those two wheels were turned toward the center of the car more, and more, and more, until they're turned almost 90 degrees and are trying to roll straight toward each other. With even just a little incorrect toe, we refer to the tire's "leading edge". In our exaggerated example, now it's easy to see the outer edge of the tread is the leading edge. It is the part that comes down the road first.

Now visualize a pencil being held straight up with its eraser sitting on the table or desk top. Push down on the pencil, then drag it sideways across the table. The leading edge will fold under, tear off eraser crumbs, and the trailing edge will lift up off the table. No wear will take place to the trailing edge. The same thing happens to the tire. For each block of rubber on the tread, the leading edge will scrub off, and the trailing edge will lift up off the road surface, so little wear will take place on that part. You can feel that wear when you lightly rub your hand over those blocks of rubber. One way your fingers will glide over those ramps of rubber, and the other way your fingers will catch on the sharp edges. Based on that observation, you can tell the car owner which way the total toe adjustment is off, and you know what to expect to find on the alignment computer. When that wear is bad enough, you can even see it when just standing next to the car. It is also possible to observe that wear by running your hands from side to side across the tread, but I need some time to figure out whether it's caused by excessive toe-in or toe-out.

Also be aware the excessive total toe on the front can cause steering wander and a very tiring car to to drive. The tires will be steering in different directions. By the way, they walk in toward each other or away from each other, until the blocks of rubber can't flex any more, then they snap back and start that all over. That is what causes that feather-edge pattern you feel when running your fingers over the tread. The car can only follow one of the tires. In the U.S, that is usually the right one since roads lean to the right so water will run off. By leaning that way, a little more of the car's weight will shift to the right tire, so it sticks to the road a little more than the left one. Now, when you cross an intersection, or hit a bump on the road, more vehicle weight might momentarily shift to the other tire, then the car wants to follow that one. You have to suddenly correct that change by steering the other way. That is what gives the appearance of steering wander.

Related to that is when driving in a cross-wind. Suppose you have excessive total toe-in like you started with, and both wheels are steering toward the center of the car. If a wind blows from left to right, it pushes on the car body which puts more weight on the right tire. That tire will steer the car to the left, against the wind. That will give a feeling of little reaction to driving in windy conditions. The opposite is much more irritating and miserable when you have excessive toe-out on the front. A wind blowing from left to right puts more weight on the right tire, which already wants to steer to the right. This is where the car over-reacts to a gust of wind. You'll be constantly fighting the steering to keep the car going straight.

Monday, August 10th, 2020 AT 7:21 PM