Monday, March 24th, 2025 AT 9:26 AM

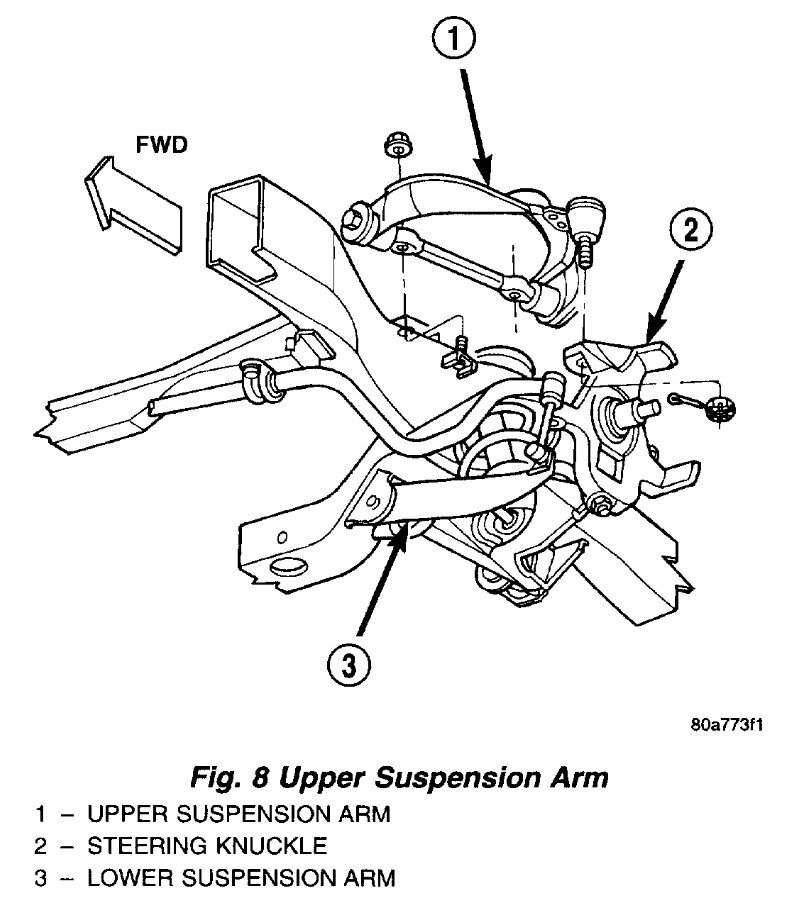

I've managed to get out the old bushings w a 3-jaw puller (I changed it to a 2 jaw see pic) then a big C clamp on 2nd one. I pressed in the new one with C clamp on one side but can't get 2nd one in with that middle bar. My tool is closed at the other end of c clamp. What technique can I use or tool to press in the 2nd one? That middle bar sure blocks a lot!