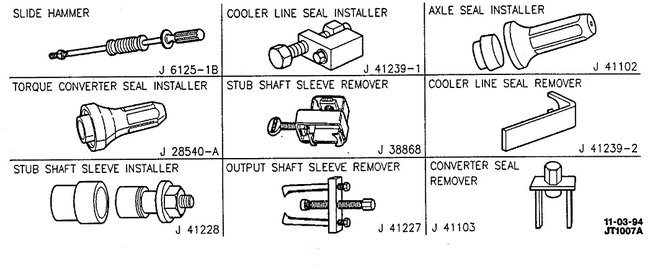

Yes, it can be replaced in-car, but that is not going to solve the noise. The tool you need is number is J 41227 shown in the middle of the bottom row in this drawing.

I've been fooled by this a few times, but the half shaft doesn't rotate nearly fast enough to cause a noise or vibration. The humming you're hearing is almost sure to be caused by one of the front wheel bearings. This is extremely common on any front-wheel-drive vehicle. The advantage to this bolt-on design used by GM is if you replace the wrong bearing, it doesn't get destroyed by removing it, so you can put the old one on the other side.

There's two ways to verify my suspicion. My preferred method was to raise the car on a hoist, run it in gear, then listen next to each bearing with a stethoscope. One will have a rumble that makes you think it's noisy, but then when you check the other one, it will be much louder, and obvious.

An alternate way to check for a noisy bearing is to raise that tire off the ground with the car in "neutral", reach over the tire and wrap your fingertips lightly around part of the coil spring, then slowly rotate the tire with your other hand. You'll feel the vibration in the coil spring. That's the vibration that sets up the hum you hear.

With Fords, most imports, and older Chrysler products that use a pressed-in wheel bearing, there was a common clue to determine which one was noisy. You absolutely can not go by where it sounds like the noise is coming from. You'll be wrong half of the time. With this design, most of those bearings are real inexpensive, but they have to be destroyed to remove them. That means if you replace the wrong one, you end up replacing both of them. The common clue to determining which is the noisy one is to drive around 35 mph, and turn slightly as in when changing lanes. If the noise gets louder when you turn left, it's the right bearing that's noisy. The noise gets louder when vehicle weight shifts onto that side. The noise usually also gets real quiet when you turn toward the noisy bearing.

This trick of turning slightly to identify the noisy bearing rarely works with the bolt-on style. Also, to be sure this adds to the frustration, the noise transmits through the body and can sound like it's coming from the opposite side it originated from. This is where you will definitely want to listen with a stethoscope or do the coil spring trick.

To add to the insult, a lot of GM cars with anti-lock brakes have the wheel speed sensor built into the wheel bearing. Those sensors develop an extremely weak signal to start with, then with a little normal wear, often in as little as 15,000 miles, the bearing has enough play to let the sensor move away from the tone ring, and the speed signal drops out. The dealers' scrap metal bins are full of those bearings. Many of those ABS Computers will only set one wheel speed sensor fault code at a time. If a customer waits for months to get the sloppy bearing replaced, there's plenty of time for this to happen to the other front bearing, but there won't be a diagnostic fault code to tell us about that. You only know about the first sensor problem. When that bearing is replaced and you go out for a test-drive is when the computer sees the second problem and sets another fault code. Customers are frustrated because they think you didn't diagnose the problem correctly. Mechanics are frustrated because they had no way of knowing about the second problem until after the first one was fixed.

Another thing to be aware of is these bearings are usually available with or without the wheel speed sensor. It's the same bearing, but you'll usually find the one with the sensor costs less than the one without the sensor. I think that's because the one with the sensor is more common so they buy them in bulk at a better price. If your car has antilock brakes, you have to buy a bearing with the built-in wheel speed sensor. If you don't have anti-lock brakes, still look at the prices of both. You can install the one with the sensor if it's less expensive. There's just nothing to plug the sensor into.

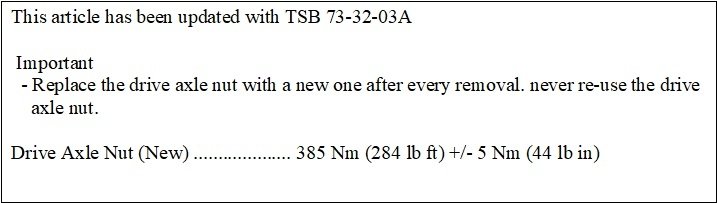

Also be aware that with all types of these wheel bearings, they will instantly become noisy if any vehicle weight is placed on them when the axle nut is not tightened to specs. That even occurs when there's no engine or transmission in the car and you push it across the shop. The new bearing nut must be tightened with a click-type torque wrench before the car is set onto the tires. The most common torque spec is 180 foot-pounds, but a few imports call for considerably less. Some GM vehicles specify a lot more. This is a perfect example, as shown in the second drawing. This is a "torque-to-yield" nut, meaning the threads peel a little when it is tightened. Those nuts are supposed to be replaced after they've been loosened for any service. Most new wheel bearings come with a new nut when they're required. Also note the really high torque spec for your car. They list 284 foot-pounds which is more than most large trucks call for.

Images (Click to make bigger)

SPONSORED LINKS

Saturday, July 24th, 2021 AT 1:04 PM