Hi,

This can be the result of a few different things. First, it could simply be low on transmission fluid. Second, there could be a partial blockage in the system reducing line pressure. Third, the clutch plates could be worn and simply slipping.

_______________________

First, check the transmission fluid and its condition.

Here are the directions for checking fluid and condition. The attached pic correlates with the directions. The problem you may have is there is no dipstick. You need to have a specific one. Often times, parts stores sell them.

______________________

2007 Chrysler 300 V6-2.7L VIN R

Check Oil Level

Vehicle Maintenance Fluids Fluid - A/T Service and Repair Procedures 42RLE Automatic Transmission Check Oil Level

CHECK OIL LEVEL

CHECK OIL LEVEL

1. Verify that the vehicle is parked on a level surface.

2. Remove the dipstick tube cap.

WARNING: Risk of accident from vehicle starting off by itself when engine running. Risk of injury from contusions and burns if you insert your hands into the engine when it is started or when it is running. Secure vehicle to prevent it from moving off by itself. Wear properly fastened and close-fitting work clothes. Do not touch hot or rotating parts.

3. Actuate the service brake. Start engine and let it run at idle speed in selector lever position "P".

4. Shift through the transmission modes several times with the vehicle stationary and the engine idling

5. Warm up the transmission, wait at least 2 minutes and check the oil level with the engine running. Push the Oil Dipstick 9336 into transmission fill tube until the dipstick tip contacts the oil pan and pull out again, read off oil level, repeat if necessary.

NOTE: The dipstick will protrude from the fill tube when installed.

pic 1

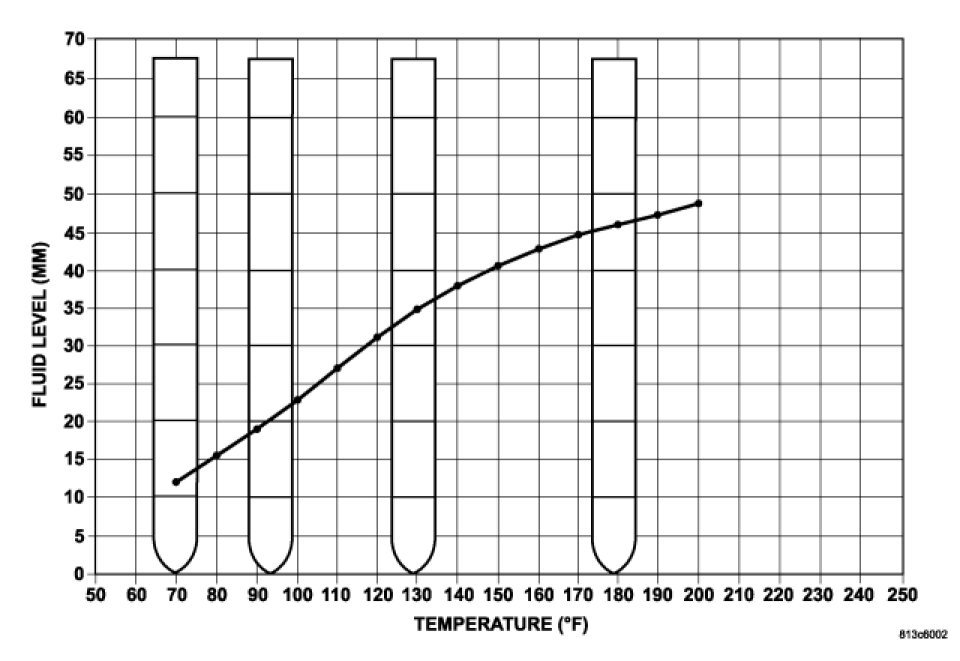

42RLE Fluid Temperature Chart

6. Check transmission oil temperature using the appropriate scan tool.

7. The transmission Oil Dipstick 9336 has indicator marks every 10 mm. Determine the height of the oil level on the dipstick and using the height, the transmission temperature, and the Transmission Fluid Graph, determine if the transmission oil level is correct.

8. Add or remove oil as necessary and recheck the oil level.

9. Once the oil level is correct, install the dipstick tube cap.

_______________________________

Next, if there is a line pressure issue, the check engine light should be on when the engine is running. So, if the clutches are bad or there is a pressure issue, we need to scan the computer for codes. The vehicle is new enough that I suggest scanning the CAN bus system. CAN stands for controller area network. Basically, the modules and computers are tied together via a few wires. Here is a video showing how it is done.

https://youtu.be/InIlnsjOVFA

_______________________________

I wish I had an easy answer, but so many things have changed. Simply checking the fluid has turned into requiring special tooling.

Regardless, let me know if any of this helps. Also, feel free to ask any questions you may have.

Take care,

Joe

Image (Click to make bigger)

SPONSORED LINKS

Saturday, November 14th, 2020 AT 6:47 PM