Hi and thanks for using 2CarPros. Com.

A knock sensor will not prevent the vehicle from moving. First, check to make sure the transmission fluid is clean and full. Next, clutches do not go bad all at once. You will notice the transmission slipping first. This can continue for a long time before the vehicle will no longer move.

Since this seems to have happened all at once, check to confirm you do not have a broken CV joint or axle. A broken axle on one side of the vehicle will prevent it from moving.

Next, Even if the transmission is full, I would first recommend removing the transmission pan and replacing the transmission filter. I have had individuals who were sure a transmission was bad very happy when I told them it was a plugged filter. If it is dirty enough, with the engine off, debris can settle to the bottom of the pan. At start up, the transmission may work for a short time and then fail as you described because the pump has picked up enough debris to lower the pressure enough to prevent gear engagement.

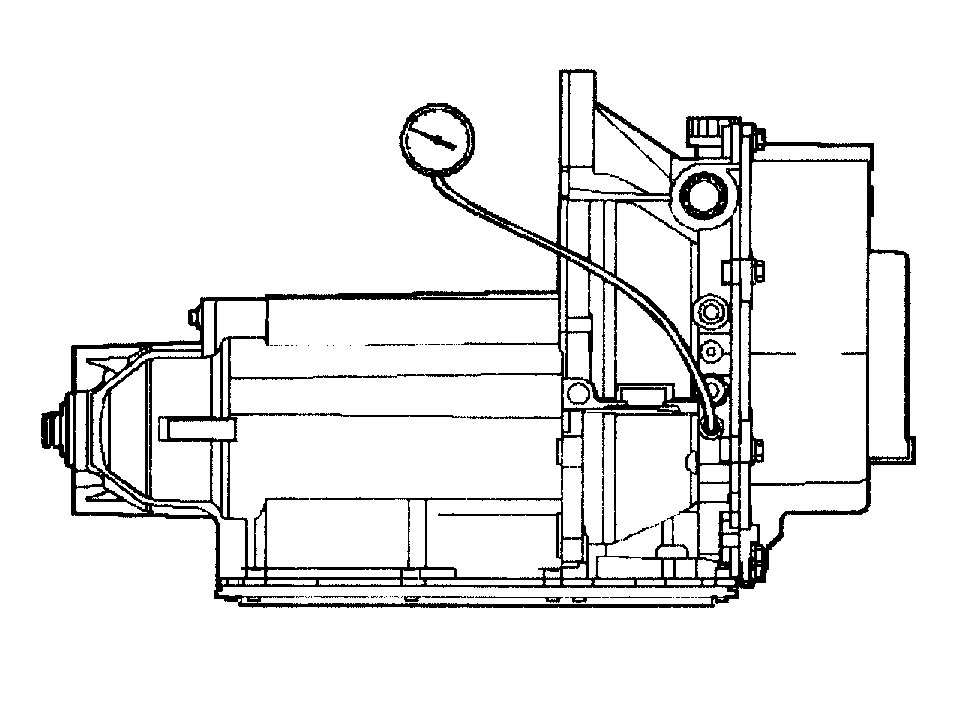

You may want to check and confirm the transmission line pressure is within the manufacturer's specs. Here are the directions for do it. The last picture correlates with these directions.

___________________

LINE PRESSURE CHECK PROCEDURE

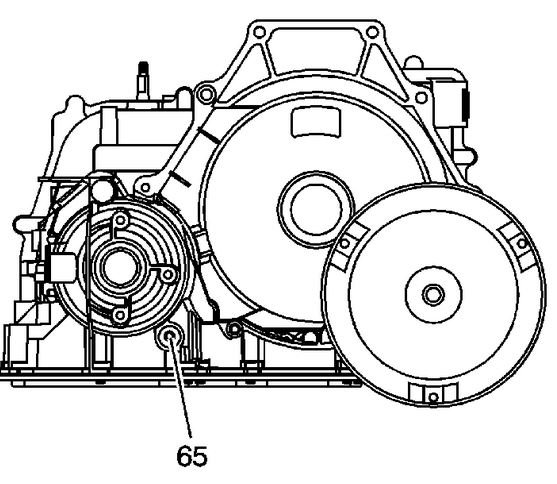

imageOpen In New TabZoom/Print

Line Pressure Check Procedure

Caution: Keep the brakes applied at all times in order to prevent unexpected vehicle motion. Personal injury may result if the vehicle moves unexpectedly.

Notice: The total test running time should not be longer than 2 minutes. Running the test longer than 2 minutes may damage the transaxle.

Line pressures are calibrated for two sets of gear ranges - DRIVE-PARK-NEUTRAL, and REVERSE. This allows the transaxle line pressure to be appropriate for different pressure needs in different gear ranges. Before performing a line pressure check, verify that the pressure control solenoid for the transaxle is receiving the correct electrical signal from the PCM.

Important: Some conditions may be intermittent, therefore this test should be performed at least 3 times.

1. Install the scan tool.

2. Start the engine and set the parking brake.

3. Check for diagnostic trouble codes, including the diagnostic code for a stored pressure control solenoid.

4. Repair the vehicle if necessary. Include the following areas:

Inspect the fluid level

Inspect the manual linkage at the transaxle

Install or connect the scan tool.

Install or connect the oil pressure gage at the line pressure tap.

5. Put the gear selector in PARK and set the parking brake.

6. Start the engine and allow the engine to warm up at idle.

7. Access the PCS Control test on the scan tool.

8. Increase DESIRED PCS in 0.1 amp increments. Read the corresponding line pressure on the pressure gage. Allow the pressure to stabilize for 5 seconds after each current charge.

Important: Before installing the line pressure plug, apply GM P/N 12345382 (Canadian P/N 10953489) to the thread of the line pressure plug.

9. Remove oil pressure gage and install line pressure plug.

If your pressure readings differ greatly from the line pressure table, refer to the Diagnosis Tables contained in this section.

The scan tool is only able to control the pressure control solenoid in PARK and NEUTRAL with the vehicle stopped. This protects the clutches from extremely high or low pressures in DRIVE or REVERSE ranges.

Refer to Line Pressure.

The pressures in the table assume a temperature of 70°C (158°F). The pressure will vary with a change in temperature.

_____________________________________

The directions for checking fluid provided are accurate. Make sure the engine is at operating temp, too, when checking. ATF expands as it heats. Checking cold will give a false reading.

Let me know if you have other questions or need help.

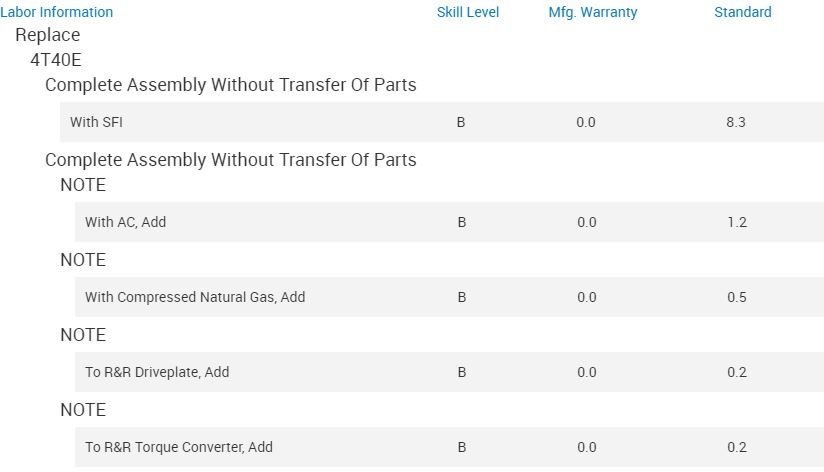

By the way, to help you determine an approximate cost for removal and replacement, I have attached pictures 2 and 3. Picture 2 shows the cost of parts. Note that the parts are original equipment and what one could expect to pay from a dealership.

The 3rd picture are labor indicators. Add up the number of hours based on your vehicle's equipment. Then, determine the shops hourly rate and multiply the two for labor cost.

This will get you in the ball park. However, if your transmission is rebuilt, it should be somewhat lower, but one doesn't know for sure what needs replaced internally until the tear down.

I hope this is helpful. Let us know if you have other questions or need help.

Take care,

Joe

Images (Click to make bigger)

Thursday, November 1st, 2018 AT 5:23 PM