DTC P0420: CATALYST SYSTEM EFFICIENCY BELOW THRESHOLD (BANK 1)

CIRCUIT DESCRIPTION

The ECM uses the air-fuel ratio (A/F) sensor and the heated oxygen sensor 2 to detect deterioration in the front catalyst.

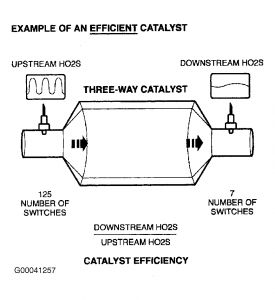

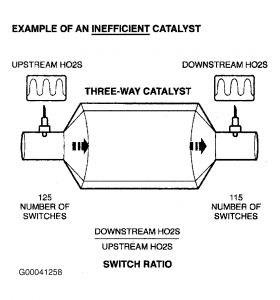

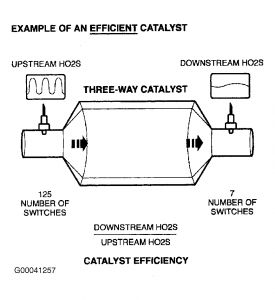

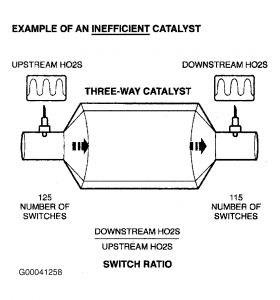

Fig. 92: Catalyst System Efficiency Theory

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

In order to detect deterioration in the front catalyst, the ECM calculates Oxygen Storage Capacity (OSC) in the catalyst based on voltage output of the heated oxygen sensor 2 while performing the "active air-fuel ratio control" instead of the conventional detecting method which uses the locus ratio.

The OSC is an indication value of the catalyst oxygen storage capacity and is used for representing how much the catalyst can store oxygen. When the vehicle is driving with a warm engine, the "active air-fuel ratio control" is performed for approximately 15 to 20 seconds. When it is performed, the air-fuel ratio is forcibly regulated to go LEAN or RICH by the ECM, and if a RICH and LEAN cycle of the heated oxygen sensor 2 is long, the OSC will become greater, and greater OSC basically capability of the catalyst are mutually related, the ECM judges if the catalyst has deteriorated based on the calculated OSC value.

If your mechanic can ead live data from the O2 sensors, have him look at the downstrem sensors for too much switching, when this happens, the converter is no good!

SPONSORED LINKS

Tuesday, August 12th, 2008 AT 4:31 PM