Hello

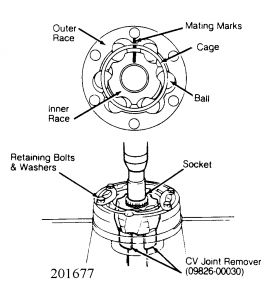

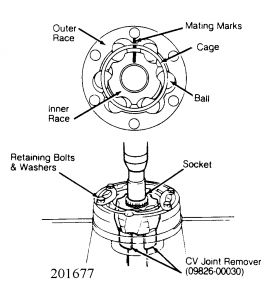

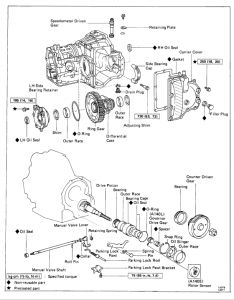

I will do the best I can to explain and if you still don't understand I will forward to another moderator. If we look at the first pic, the side gear shaft has a snap ring on the end of the shaft that helps hold it in to the transaxle. You need quite a bit of force to pull the side gear shaft out to over come the snap ring holding it in. Thus the use of the slide hammer. The ones I have seen stick out past the end of the axle. . .. . ..long. You may not have one or be able to get one. You might consider checking with a transmission shop and see if they would rent you one. I would imagine it bolts up to the shaft and the nuts that hold the left drive axle shaft to it then hold the slide hammer to it. A couple of good slides and out it should come.

In another section discussion seal replacement, I have attached that for you, as you see in step 5 you need a special tool, SST 09350-32010 or equivalent to drive out the side shaft. In step 7 you need a special tool to install the seal. When you get to step11, you use a different special tool to install.

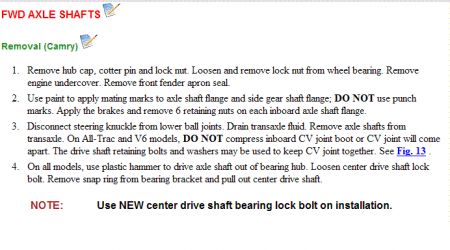

1. Remove dust cover and fender apron seal.

2. Drain out approximately 1 quart of transaxle fluid.

3. Remove left hand driveshaft as described under ``Speed Sensor, Replace.''

4. Remove speed sensor as described under ``Speed Sensor, Replace.''

5. Using tool SST 09350-32010 or equivalent, drive out side gear shaft.

6. Remove side bearing retainer.

7. Press oil seal out of retainer, and using tool SST 09359-32010 or equivalent, press in new seal to depth of .106 inch.

8. Coat lip of oil seal with suitable grease.

9. Clean bolt and case threads of side bearing retainer attaching bolts, coat threads of bolts with suitable sealer, and torque bolts to 14 ft. lbs.

10. Using tool SST 09520-32010 or equivalent, drive in side gear shaft until it contacts pinion shaft.

11. Install speed sensor as described under ``Speed Sensor, Replace.''

12. Install driveshaft as described under ``Speed Sensor, Replace.''

13. Fill transaxle with approximately 1 quart of transaxle fluid.

You may not have the special tools for this task.

If I understand the next part of your question about the gear being pressed on, I have attached a pic of that. As you see you can use a plastic hammer to drive that apart.

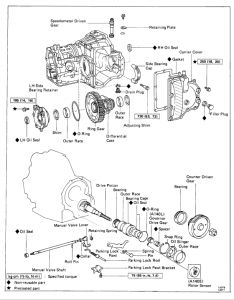

Your question about the covering at the side. If we are talking about the same thing, I have attached a pic, you are looking at the bearing retainer which gets you into the deferential area. If you remove this you will need to replace the O ring also.

When reading your reply I sense frustration. . .. . ...I would be. The problem with some areas, like transmissions, they require many different special tools and equipment. Many shops, much less home owners don't have them. Thus many shops contract some things out to specialized shops. The shop you take your car to replaces the front struts on the car. Afterwards, they send it over to the front end shop they work with to have the front end aligned. Once finished the car is returned and you pick it up at the original place. For me I remove the transmissions and drop them off to the shops and pick them up once repaired.

My concern for you, you appear to have the knowledge and skill to perform this task. It is the lack of the special tools and equipment to do it. Another concern is if this axle broke as you said, then seals should be replaced also. The other concern is why did it brake? Did the bolts shear, did the nuts loosen and it began to vibrate and wobble and the stress cause the others to shear? Did the transaxle on that side start to drag and the force of the forward movement of the tire connected to the axle shear the bolts? There may be more there that we can not see.

If these pics do not help you out, if you would like, let me know and I will have one of the other moderators review and assist if possible.

Mechanics are very frustrating at times. You are doing a great job. . .we will do what we can to assist.

Hope this helps

Monday, May 27th, 2019 AT 2:49 PM

(Merged)