This is a complex operation and not for the novice ??

Timing Drive Components-Windsor Engine

Special Tool(s)

Fig. 274: Identifying Special Tools

Courtesy of FORD MOTOR CO.

Materials

Fig. 275: Material Specifications

Courtesy of FORD MOTOR CO.

Removal

CAUTION:Since the engine is not free-wheeling, the timing procedures must be followed exactly or piston and valve damage can occur.

Remove the engine front cover. Refer to ENGINE FRONT COVER .

Remove the crankshaft sensor ring from the crankshaft.

Fig. 276: Removing Crankshaft Sensor Ring From Crankshaft

Courtesy of FORD MOTOR CO.

CAUTION:Unless otherwise instructed, at no time when the timing chains are removed and the cylinder heads are installed is the crankshaft or camshaft to be rotated. Severe piston and valve damage will occur.

Fig. 277: Positioning Crankshaft

Courtesy of FORD MOTOR CO.

Position the crankshaft with the keyway at the 12 o'clock position.

Install and fully tighten the special tools on both camshafts.

Fig. 278: Installing Fully Tighten Special Tools On Both Camshafts

Courtesy of FORD MOTOR CO.

Remove the timing chain tensioning system from both timing chains.

Remove the bolts.

Remove the timing chain tensioners.

Remove the timing chain tensioner arms.

Fig. 279: Removing Timing Chain Tensioning System From Both Timing Chains

Courtesy of FORD MOTOR CO.

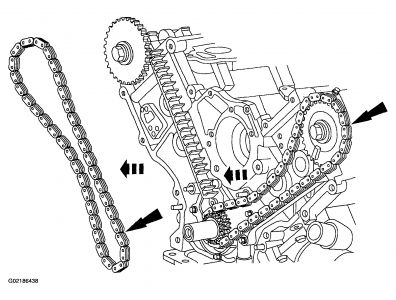

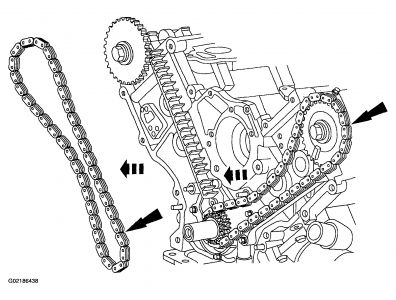

Fig. 280: Removing RH And LH Timing Chains And Crankshaft Sprocket

Courtesy of FORD MOTOR CO.

CAUTION:Unless otherwise instructed, at no time when the timing chains are removed and the cylinders heads are installed is the crankshaft or camshaft to be rotated. Severe piston and valve damage will occur.

Remove the RH and LH timing chains and the crankshaft sprocket.

Remove the RH timing chain from the camshaft sprocket.

Remove the RH timing chain and from the crankshaft sprocket.

Remove the LH timing chain from the camshaft sprocket.

Remove the LH timing chain and crankshaft sprocket.

Remove both timing chain guides.

Remove the bolts.

Remove both timing chain guides.

Fig. 281: Removing Timing Chain Guides

Courtesy of FORD MOTOR CO.

Installation

CAUTION:Timing chain procedures must be followed exactly or damage to valves and pistons will result.

Fig. 282: Compressing Tensioner Plunger, Using A Vise

Courtesy of FORD MOTOR CO.

Compress the tensioner plunger, using a vise.

Install a retaining clip on the tensioner to hold the plunger in during installation.

Fig. 283: Installing Retaining Clip On Tensioner To Hold Plunger In During Installation

Courtesy of FORD MOTOR CO.

Remove the tensioner from the vise.

If the copper links are not visible, mark two links on one end and one link on the other end, and use as timing marks.

Fig. 284: Identifying Timing Marks On Timing Chain

Courtesy of FORD MOTOR CO.

Fig. 285: Installing Timing Chain Guides

Courtesy of FORD MOTOR CO.

Install the timing chain guides.

CAUTION:Do not turn the engine over with the camshaft positioning tool or damage to the camshaft sprocket or the bolt can occur.

Fig. 286: Installing Camshaft Positioning Tool

Courtesy of FORD MOTOR CO.

Fig. 287: Positioning Camshaft

Courtesy of FORD MOTOR CO.

Install the Camshaft Positioning Tool.

NOTE:Slightly loosen the camshaft holding tools to allow slight camshaft movement.

Pre-position the camshafts.

Rotate the LH camshaft with the Camshaft Positioning Tool until the timing mark is approximately at 12 o'clock.

Rotate the RH camshaft with the Camshaft Positioning Tool until the timing mark is approximately at 11 o'clock.

Tighten the Camshaft Holding Tools to maintain camshaft pre-positioning.

CAUTION:Unless otherwise instructed, at no time when the timing chains are removed and the cylinder heads are installed is the crankshaft or camshaft to be rotated. Severe piston and valve damage will occur.

CAUTION:Rotate the crankshaft counterclockwise only. Do not rotate past position shown or severe piston and valve damage can occur.

NOTE:The number one cylinder is at top dead center (TDC) when the stud on the engine block fits into the slot in the handle of the special tool.

Fig. 288: Rotating Crankshaft Counterclockwise

Courtesy of FORD MOTOR CO.

Position the crankshaft so the number one cylinder is at TDC with the special tool.

Remove the Crankshaft Holding Tool.

Install the crankshaft sprocket, make sure the flange faces forward.

Fig. 289: Identifying Direction Of Flange For Installing Crankshaft Sprocket

Courtesy of FORD MOTOR CO.

Position the lower end of the LH (inner) timing chain on the crankshaft sprocket, aligning the timing mark on the outer flange of the crankshaft sprocket with the single copper (marked) link on the chain.

Fig. 290: Aligning Timing Mark On Outer Flange Of Crankshaft Sprocket With Single Copper (Marked) Link On Chain

Courtesy of FORD MOTOR CO.

NOTE:Make sure the upper half of the timing chain is below the tensioner arm dowel.

NOTE:If necessary, use the Camshaft Positioning Tool to adjust the camshaft sprocket slightly to obtain timing mark alignment.

Fig. 291: Positioning Timing Chain On Camshaft Sprocket With Camshaft Sprocket Timing Mark Positioned Between Copper (Marked) Chain Links

Courtesy of FORD MOTOR CO.

Position the timing chain on the camshaft sprocket with the camshaft sprocket timing mark positioned between the two copper (marked) chain links.

NOTE:The LH timing chain tensioner arm has a bump near the dowel hole, for identification.

Fig. 292: Identifying Tightening Torque Of LH Timing Chain Tensioner Bolts

Courtesy of FORD MOTOR CO.

Position the LH timing chain tensioner arm on the dowel pin and install the LH timing chain tensioner.

Remove the retaining clip from the LH timing chain tensioner.

Fig. 293: Removing Retaining Clip From LH Timing Chain Tensioner

Courtesy of FORD MOTOR CO.

NOTE:The lower half of the timing chain must be positioned above the tensioner arm dowel.

Fig. 294: Aligning Timing Mark On Sprocket With Single Copper (Marked) Link On Timing Chain

Courtesy of FORD MOTOR CO.

Position the lower end of the RH (outer) timing chain on the crankshaft sprocket, aligning the timing mark on the sprocket with the single copper (marked) link on the timing chain.

NOTE:If necessary, use the Camshaft Positioning Tool to adjust the camshaft sprocket slightly to obtain timing mark alignment.

Fig. 295: Identifying Position Of Camshaft Sprocket Timing Mark

Courtesy of FORD MOTOR CO.

Position the RH timing chain on the camshaft sprocket. Make sure the camshaft sprocket timing mark is positioned between the two copper (marked) chain links.

Position the RH timing chain tensioner arm on the dowel pin and install the RH timing chain tensioner.

Fig. 296: Identifying Tightening Torque Of RH Timing Chain Tensioner Bolts

Courtesy of FORD MOTOR CO.

Remove the retaining clip from the RH timing chain tensioner.

Fig. 297: Removing Retaining Clip From RH Timing Chain Tensioner

Courtesy of FORD MOTOR CO.

As a post-check, verify correct alignment of all timing marks.

Fig. 298: Verifying Correct Alignment Of Timing Marks

Courtesy of FORD MOTOR CO.

Remove the special tool.

Fig. 299: Removing Special Tool

Courtesy of FORD MOTOR CO.

Position the crankshaft sensor ring on the crankshaft.

Fig. 300: Positioning Crankshaft Sensor Ring On Crankshaft

Courtesy of FORD MOTOR CO.

Install the engine front cover. Refer to ENGINE FRONT COVER .

Saturday, August 22nd, 2020 AT 11:15 AM

(Merged)