My bad, I apologize, the 3.4 has a belt, here are the instructions on timing belts marks.

Install or Connect

Notice: Do not bend, kink, or pry on camshaft timing belt as damage may occur.

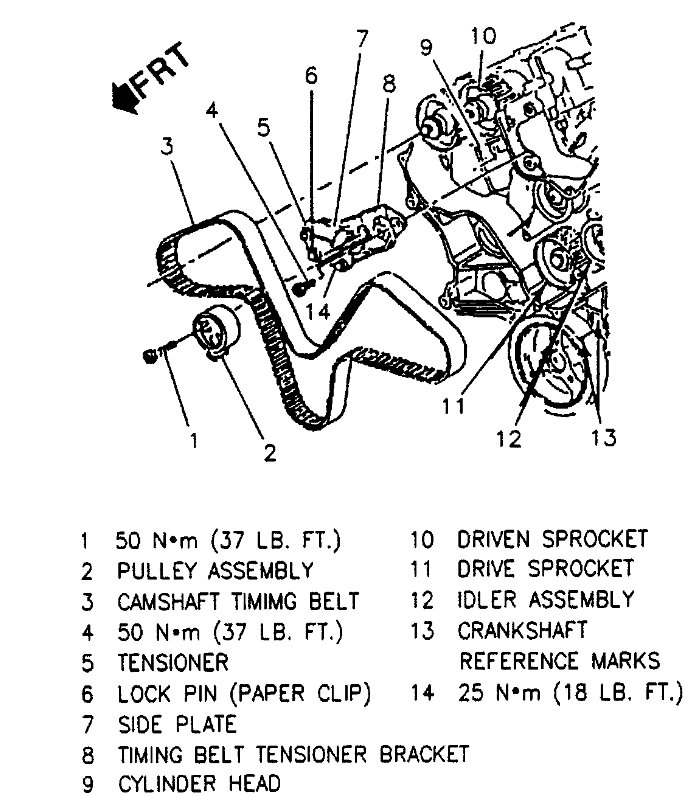

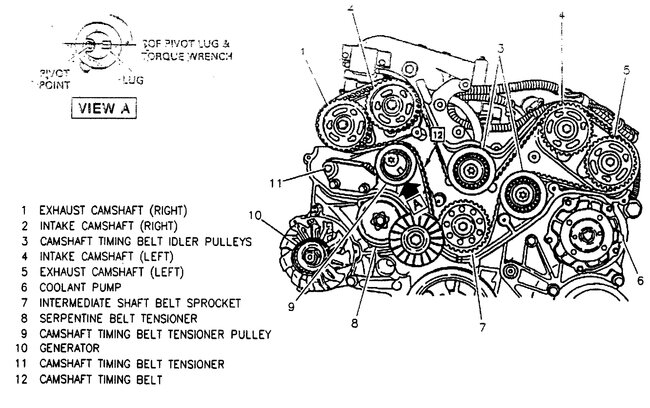

1. Camshaft timing belt by routing it around sprockets and idlers.

A. Start at intermediate camshaft sprocket and work counterclockwise when looking at front of engine.

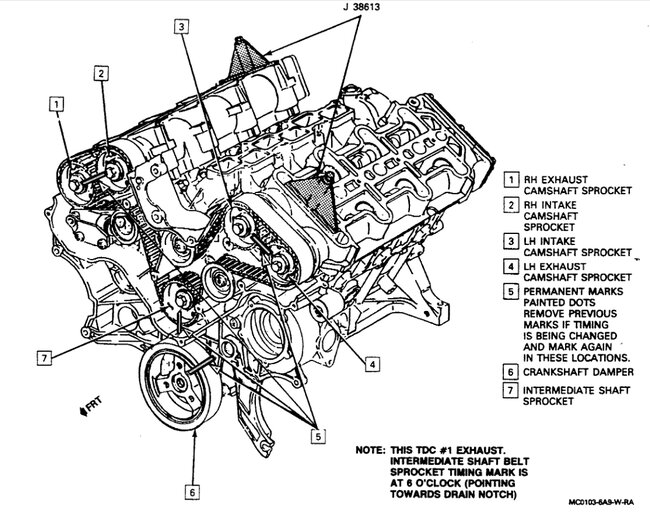

B. Make sure not to accumulate slack in belt as you work belt around sprockets.

2. Tensioner pulley.

A. Use a flat magnet, tape or cup plug to hold pivot tube in pulley.

B. Install the pulley and remove the flat magnet, tape, or cup plug.

C. Start tensioner pulley bolt. Tighten tensioner pulley bolt to 15 Nm (11 ft. Lbs.) Plus 40° using J36660, or tensioner pulley bolt to 50 Nm (37 ft. Lbs.).

3. Install tensioner bushing into side plate, if removed.

Inspect

- Bushing and appropriate holes to make sure they are clean, DO NOT LUBRICATE.

4. Loosen J38613-A to realign timing belt. Rotate rear camshaft using J38614 to set timing belt on cam sprocket. Tighten camshaft hold down tool while holding timing belt in place.

5. Timing belt tensioner.

Camshaft Timing Procedure (Belt Broken)

Tools Required

- J38616-A Camshaft timing clamps.

- J38614 Camshaft sprocket holding tool.

- J36660 Torque angle meter

1. Remove camshaft timing belt tensioner.

2. Remove tensioner pulley/arm assembly.

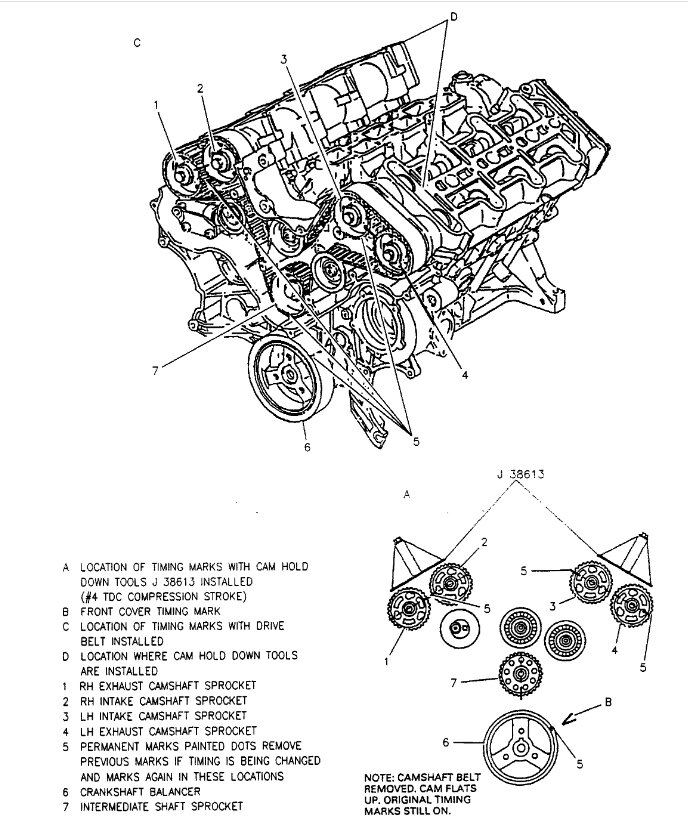

3. Set crankshaft timing mark TDC position on from cover.

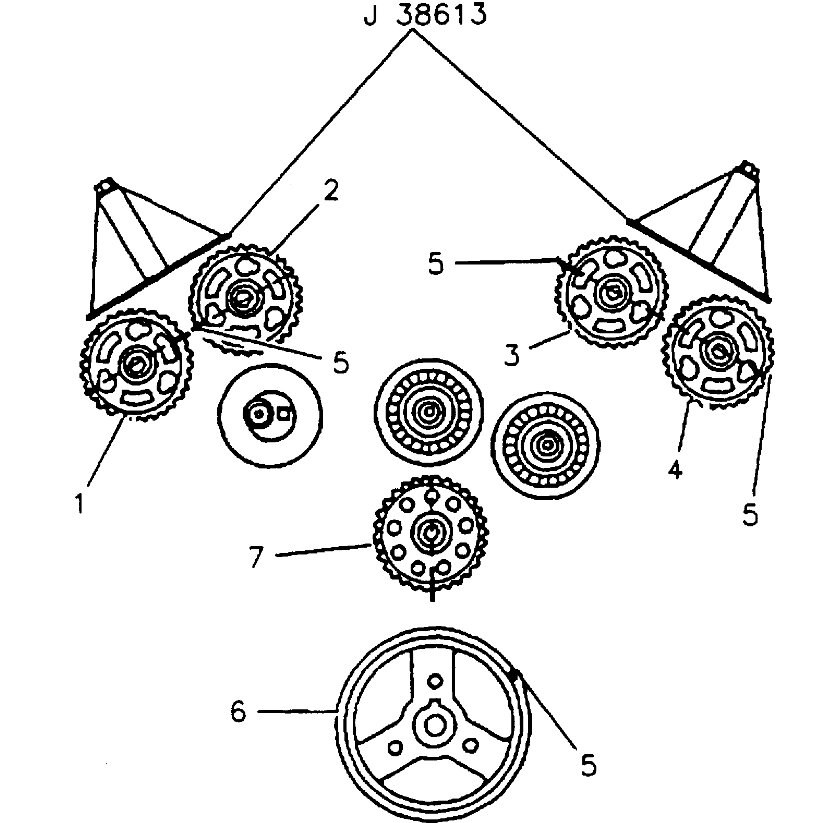

4. Install J38613-A timing belt clamps on both banks.

5. Scribe or use a paint pen to mark both camshaft sprockets inside centers, on both banks, only if original timing marks are not present.

6. Remove J38613-A timing clamp from left front bank, and rotate cam sprockets so that the timing marks are opposite of each other. Use a straight edge to verify that the timing marks are opposite of each other.

7. Install a soft jaw clamping device to the left front camshaft sprockets.

8. New camshaft timing belt by routing it around sprockets and idlers.

A. Start at intermediate camshaft sprockets and work counterclockwise when looking at front of engine.

B. Make sure not to accumulate slack in belt as you work around sprockets.

9. Tensioner pulley.

A. Use a flat magnet, tape, or cup plug to hold pivot tube in pulley.

B. Install the pulley and remove the flat magnet, tape, or cup plug.

C. Start tensioner pulley bolt. Tighten tensioner pulley bolt to 15 Nm (11 ft. Lbs.). Tighten tensioner pulley bolt to 50 Nm (37 ft. Lbs.).

10. Install tensioner bushing into side plate, if removed.

Inspect

Bushing and appropriate holes to make sure they are clean. DO NOT LUBRICATE.

11. Timing belt tensioner.

Check out the images (below). Let us know if you need anything else.

Images (Click to make bigger)

Sunday, March 31st, 2024 AT 6:40 PM