I have a good deal of experience with cars coming from a family of automotive mechanics. I do all my own auto work, so when she told us her vehicle was kicking out engine codes for bad timing chains, she could not afford to pay for this repair. I told her that I would do the job.

I've rebuilt engines before, and this project did not scare me at all.

We made the two-hour drive in the car to get it back to our place. The car acted a little weak on power but ran fine without issue. I was surprised that the car ran as well as it did.

I ordered the timing chain set. I did not order new Phasers because the car ran well and did not kick out any code for bad phasers. Nor did I order a new oil pump because there was no indication of low oil pressure and the pump appeared in good shape.

When I did the tear down and notices a lot of build up inside the valve covers. The PCV circuit has not been working. This was my first time working on a direct injection engine, so I had to do a bit of research on this problem. So, I cleaned up the intake manifold and cleaned up all the valves and guides inside the intake rails. There was a considerable amount of buildup. I cleaned up the PCV circuit and the valve covers before installing the new style gaskets.

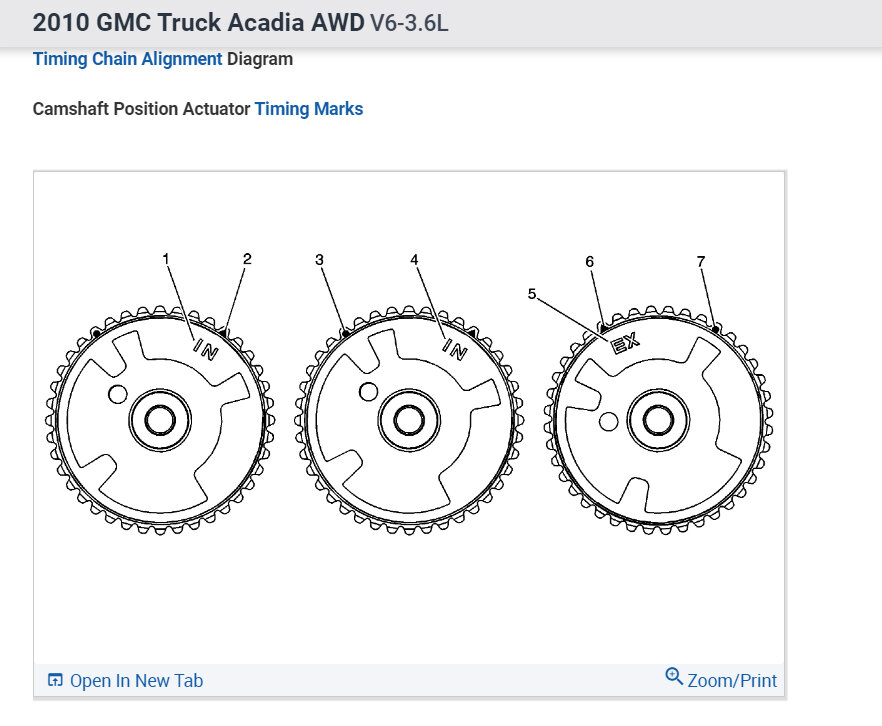

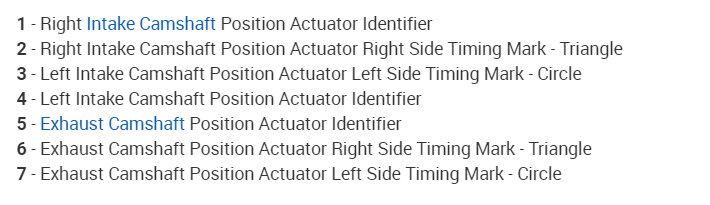

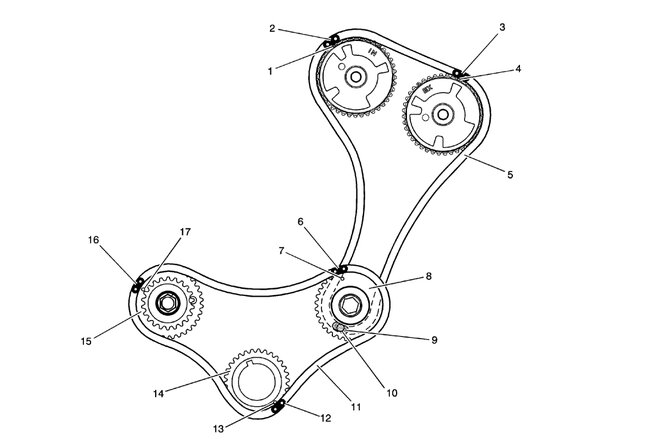

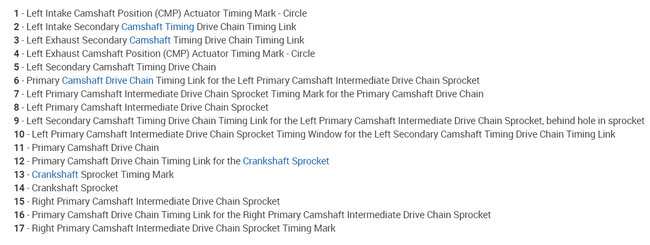

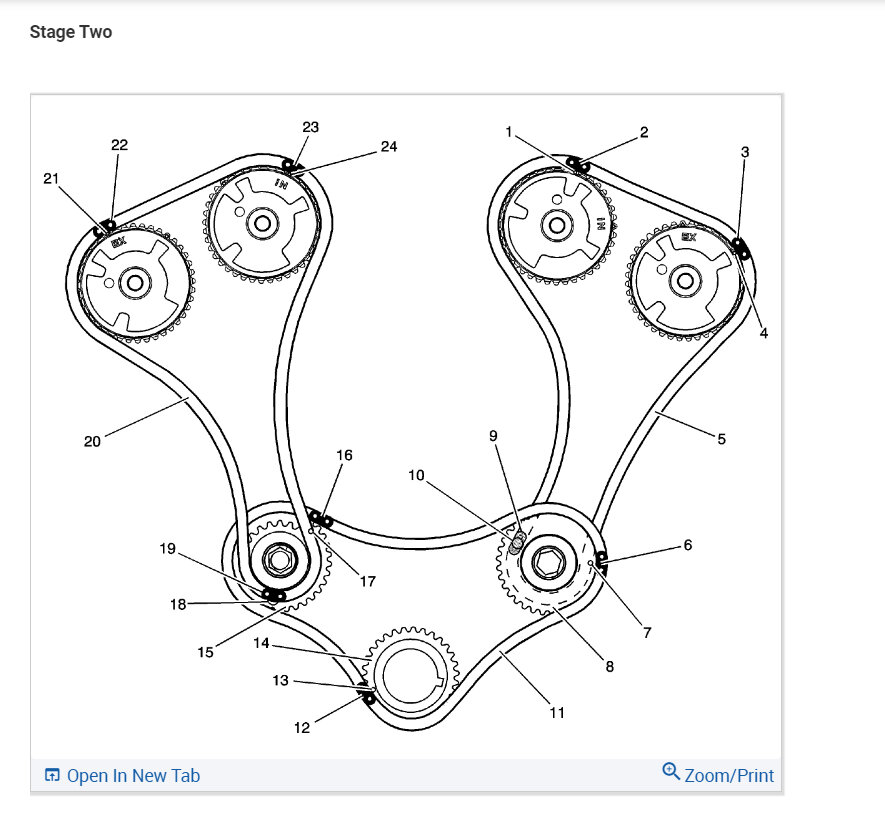

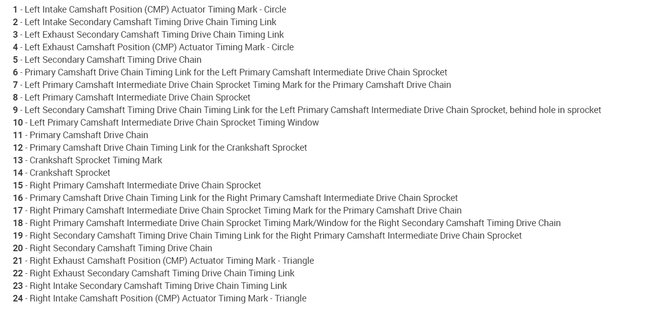

The timing chain installation went without any problems.

I followed a GM tutorial that I found online. The old chains were stretched a bit, but all the sprockets looked pretty good. The guides were worn down also. But nothing unusual otherwise. The kit included chains, guides and idler sprockets.

With what I have described, you would think that this was a slam dunk. This is where all the real problems began.

After getting everything back together, I began getting codes for a fuel pressure regulator. There is no fuel pressure regulator which leads me to the high-pressure fuel pump on the engine. A new pump didn't completely solve that problem. Now I began getting engine codes p0017 and p0019 along with misfires on 2, 4 and 6. Along with a fuel pressure code.

I added a can of Sea Foam to the crankcase and ran the engine for a while and then let it soak. I did this about four times. There was no improvement. I began looking at the wiring and found all these devices were powered by one circuit through a common relay. Switching that relay solved nothing. I tore open the wiring harness looking for a problem connected to that circuit. All six coils were connected together inside the harness. But nothing positive came from that work either.

Digging deeper, it now appeared that the cam phasers had now failed. The timing of this is bazaar. I've had the car now for six weeks and the frustration is indescribable.

So, I ordered a new set of cam phasers and four new cam sensors with four new cam solenoids and a new crank position sensor and a new fuel pressure sensor and then to top it all off. I installed a new $200 battery.

The only thing I have not replaced are the plugs and coils.

Remember, this car ran fine on the two-hour trip to get it to my house. None of this makes any sense.

The car now appeared to be repaired. My wife drove it to work and back with no issue. Later she ran a short errant and when she got back the car now had the same p0017 codes with misfires on 1 and 5.

My question of course is "how does a bad coil cause a pp0017? Even two bad coils should not cause this code.

A misfire should stand alone. It seems to me the misfires are a symptom not a cause. Earlier I had misfires on 2, 4 and 6 together. If I have this many bad coils, how is the engine even running? What is going on? I've read so many horror stories about this model vehicle, it's frightening. So many people have written posts about this same problem, but no one ever follows up to describe how it ended. From my experience, I believe they scrapped the car. This is insane. I worked for 40 years in the field of automation repair. Figuring these things out is my life's work. Nothing about this makes any sense. I've already replaced numerous parts that I knew were not the problem. All in an effort to simply eliminate the possibility.

My second question will sound stupid. Is there an issue with the dipstick on this vehicle? The oil level looks good on the dipstick. I put in five quarts. Do I need more? I've read a lot of comments about the oil level and keeping it topped off. Shouldn't the car run fine at any level as long as it shows oil on the dipstick?

Anyway, I'm running out of ideas and that just does not happen. I can't just keep throwing parts at this. I've got over $800.00 in parts already. Is it at all possible that I have an ECM failure?

I don't understand how this timing chain issue created this nightmare. Because I've heard this same story before from other owners. Some clarity would be appreciated.

Wednesday, September 28th, 2022 AT 9:46 PM