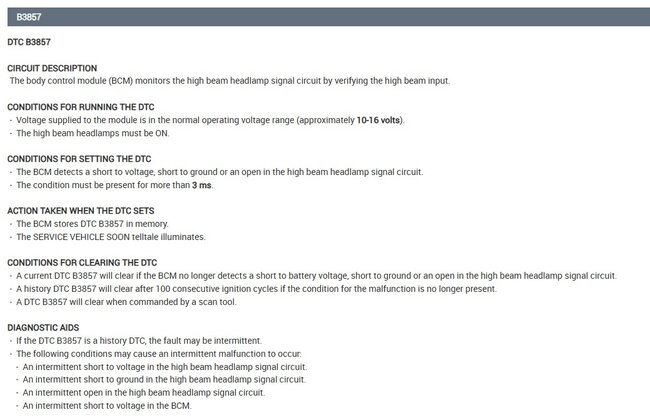

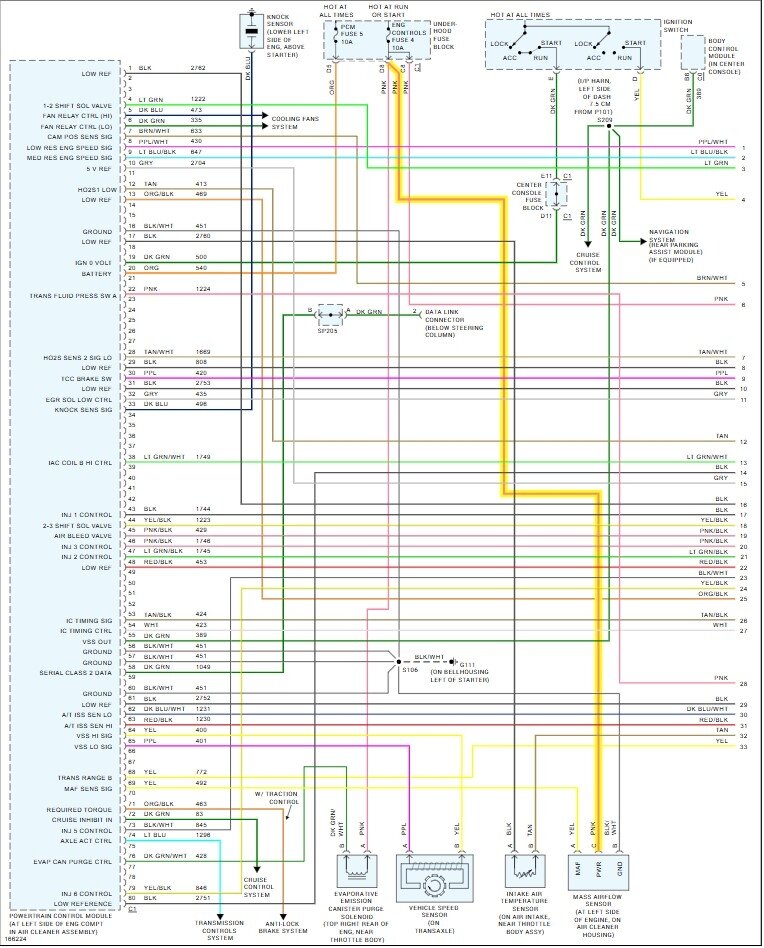

Okay, well I don't see any service info on a P0040, but the U1000 code is a network communications code, was that set in the engine computer (PCM)? Usually a module(s) will set this code when there is another module offline that the rest are not seeing, so they are pretty much telling on other modules that they are no longer able to see a specific module on the network, and this code will set. The p0449 is a Evap Vent valve control circuit code or valve issue. And the B codes are all related to the Body Control module and have to do with the headlamps, daytime running lights and fog lamp relay control.

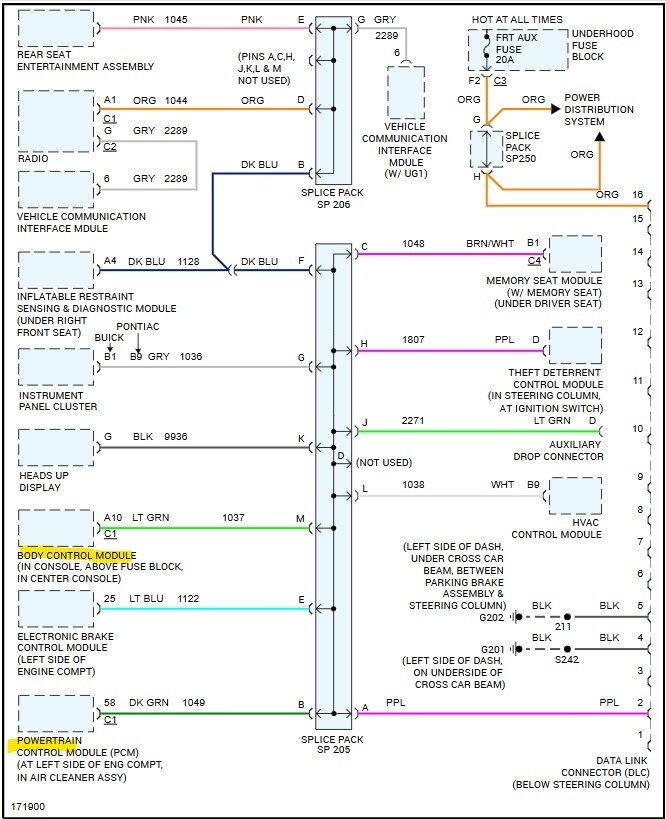

If the U1000 was set in the BCM, then we could suspect it is losing communications with possibly the engine computer (PCM) and that's causing your stalling issue, or the other way around. This network uses a "State of health" signal from each module and once that signal drops out, a U code will be set.

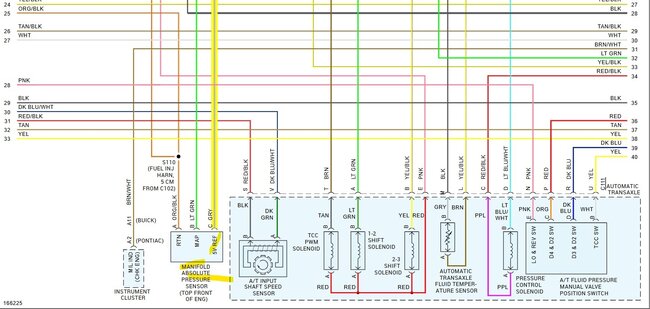

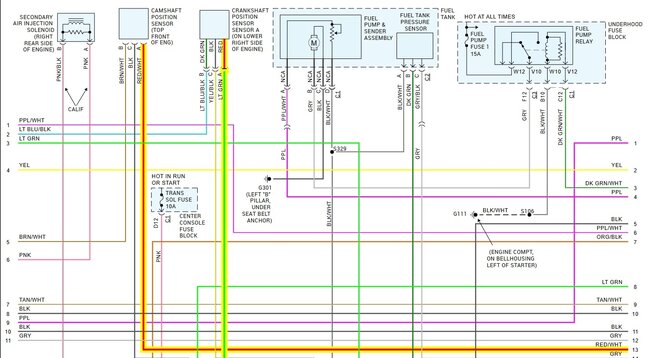

The 2nd diagram is about U communications codes. It sounds like you had the entire vehicle scanned for codes, I've added the B codes just so you have them (diagrams 3, 4, 5).

You should also notice if the Check Engine Light does not come on during Key On while the fault is occurring, if the check engine light does not come on, the PCM is down,

But you can approach this in a couple different ways, if you have your own scan tool that can try to communicate with the PCM during the fault, so after the stall out, and if you cannot communicate with it or read live data you'll know that the PCM is dropping out of the network for whatever reason, bad solder joint on the circuit board, or pin fitment issue in its connector, etc.

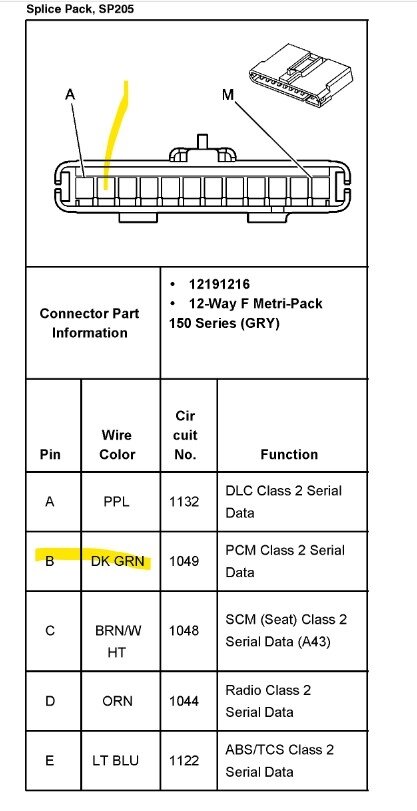

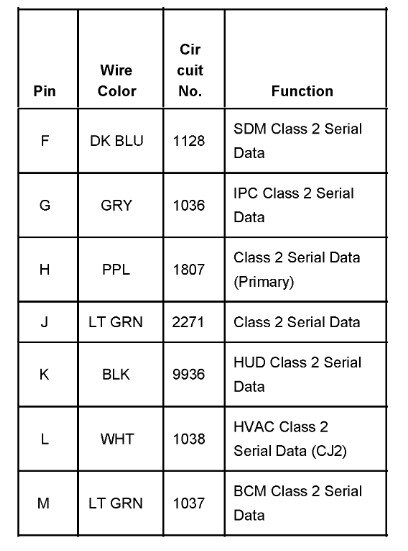

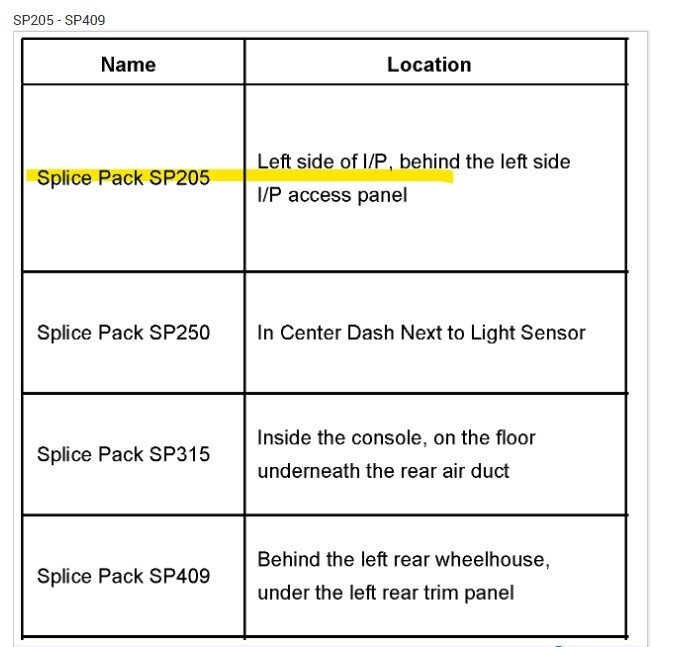

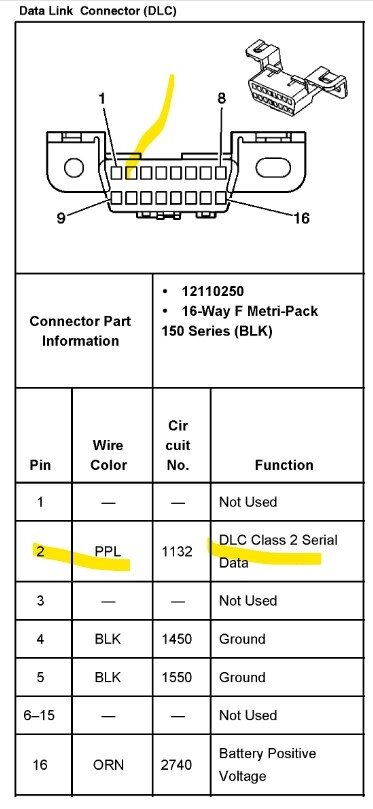

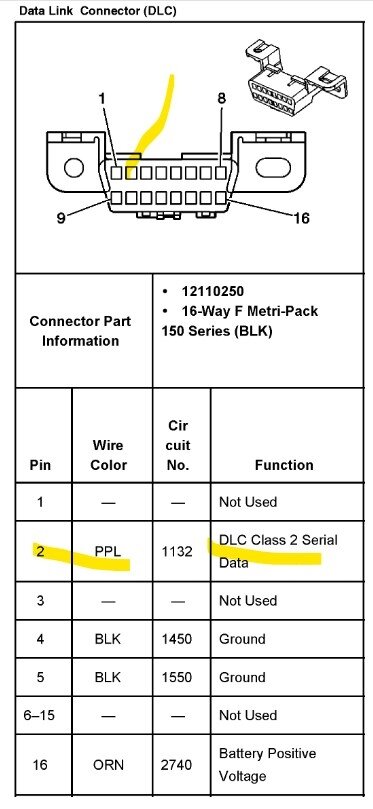

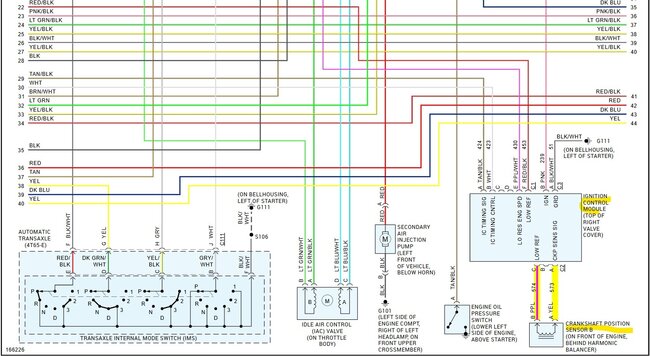

Or you can find the 2 Splice Packs SP206 and SP205, GM makes it really easy, all the modules meet up in the splice packs and are all connected by a comb that shorts them all together. Where you can de-pin a certain wire and check it for a voltage signal,

So, for example, on Splice pack 205, you'll want to check the Dark Green wire (label B -PCM) for a voltage signal,

This year it's stating a 9-14volt range, SP205 is down on the driver side lower dash, usually just to the left of the data link connector.

Diagrams 6, 7, 8, 9 are for the network, SP205 and its location, it's easier to first see if you can communicate with the PCM via a scan tool, unless the U1000 was setting in a different module, in some cases a bad module will pull down the entire network, either shorting it to ground or power.

Since you have a 10min or so window it's best to be set up ahead of time for testing, so when it stalls out you can quickly check for any voltage activity on the Dark Green wire (B) for the PCM.

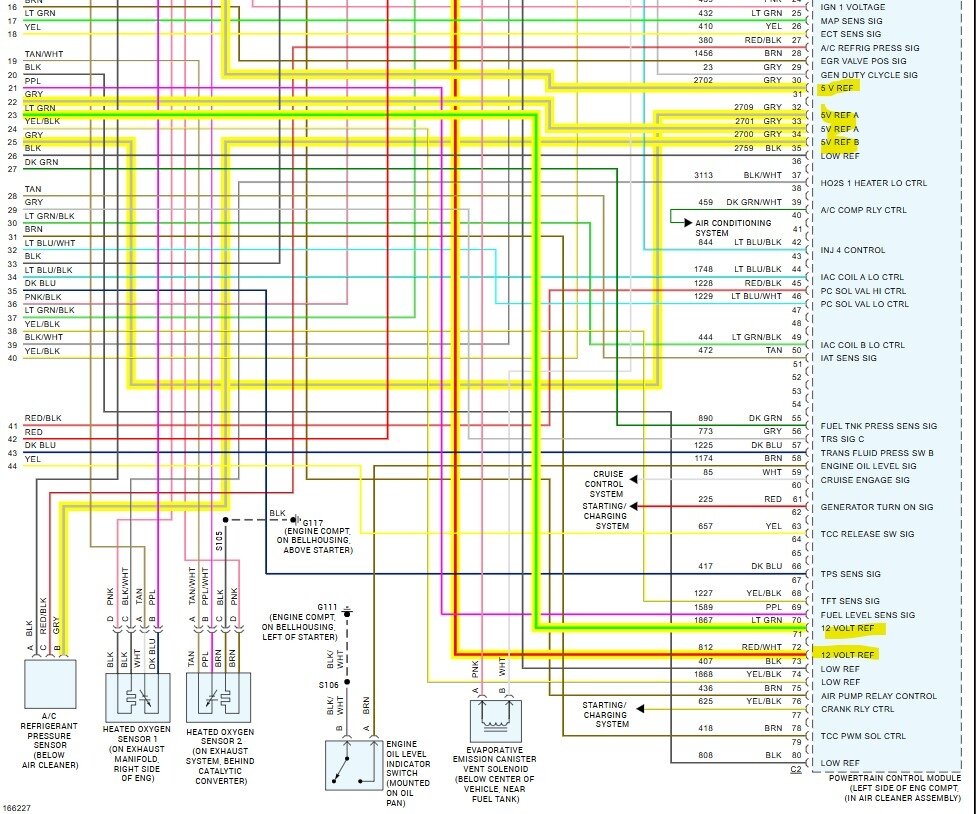

Next you need to determine why it's down, the PCM can go down if a 5volt reference is being shorted out in a sensor being pulled to ground, Any 3 wire sensor is going to use a 5volt ref, such as a throttle position sensor, MAP sensor, engine coolant temp sensor (2 wire) but should have 5v unplugged. It could also be losing power due to a bad ground or power.

I know this is a lot to take in, so if you have access to a capable scan tool that can scan other modules besides just the PCM (global OBD2). Then you could see which module is offline during the fault.

Images (Click to make bigger)

Saturday, June 1st, 2024 AT 2:31 PM