There is something else going on that you have not mentioned or have not noticed. You should not see the results of an inoperative self adjuster for a real long time, as in a year or two, or a good 20,000 to 50,000 miles. The only symptom by that time will be a brake pedal that is gradually going closer and closer to the floor.

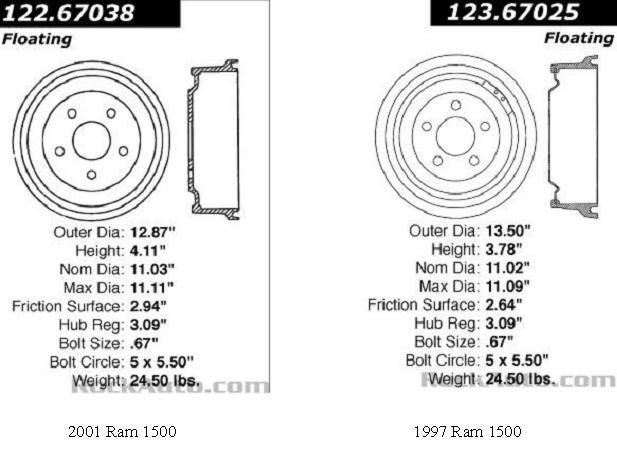

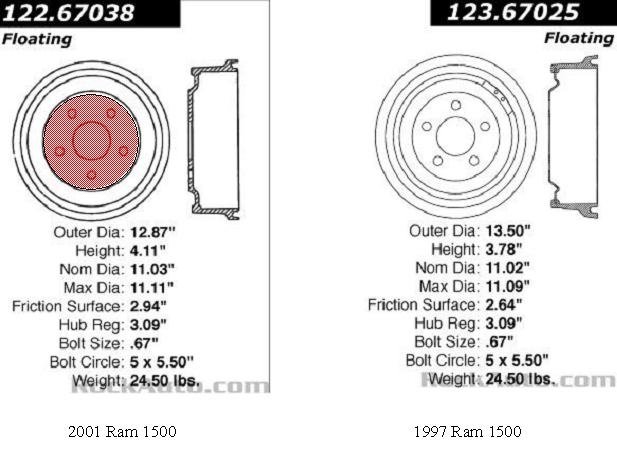

The drum you mentioned is not interchangeable on your truck. Unless specified differently by the manufacturer, the maximum a drum can be machined over-size from original is.060". That is only.030" of material removed all the way around, totaling a.060" larger diameter. Even at that, the diameter of new shoes will not match the diameter of the drum until they wear quite a bit. 1997 drums have a much different diameter, so the first thing is to get the correct drum on there before you go looking for other causes that may not exist.

Any chance you can post a photo of the brake shoes on that wheel? Without seeing it, I can only offer some suggestions of the common things I have run across and that I have caused myself. The first thing is to be sure the "leading shoe", the one toward the front of the truck, has the shorter lining, and the trailing shoe has the longer lining. The smaller front shoe simply grabs the rotating drum and tries to rotate with it. As it does, it pushes on the adjuster assembly, and that pushes the bottom of the rear shoe into the drum, to apply it. The piston in the wheel cylinder pushes the top of the rear shoe into the drum, also to apply it. (That is why it is called a "duo-servo" brake). The rear shoe does most of the stopping. That is why it needs to be a longer and/or thicker lining.

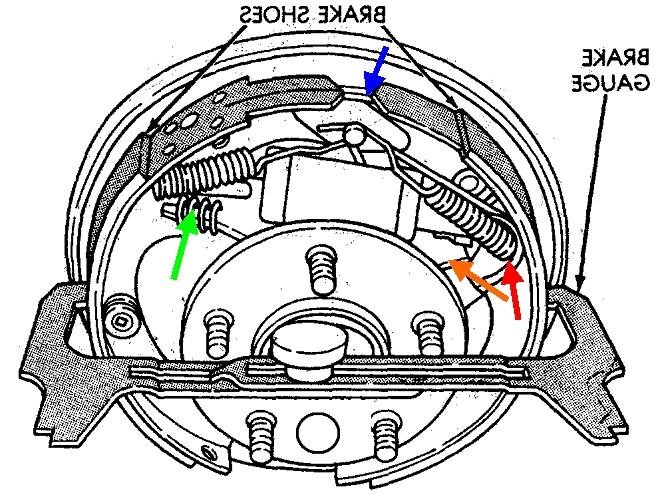

This next problem is a little harder to describe. Look at the quarter-round stamped metal guide the adjuster cable rides on. That is held in place by the hook on the rear shoe's return spring. It is easy to overlook that guide popping out and not sitting flush with the shoe. In the photo below, I added a nifty red arrow pointing to the formed tube that must be seated in the hole in the shoe. I have found it is impossible to slide that into place after the spring has been installed. You have to remove the spring, seat the guide, then reinstall the spring. Hold the guide in place with your thumb as you stretch the spring into place, otherwise it is likely to pop out again. If it does pop out, it will be pulled up and toward the axle shaft, making the distance too short for the cable. You will see the adjuster lever will be down too far, and even if it does move, it won't move far enough to advance the star wheel.

The next often-overlooked problem is a parking brake cable that is rusted in the partially-applied position. That alone will prevent the self adjuster system from doing its job. The first thing to look at is both brake shoe frames must be resting solidly against the anchor bolt on top of the backing plate. That is the blue arrow in the second drawing. I turned this drawing around so it is correct for the left rear brake. Those points are hard to see behind the springs and metal plate. Instead, push forward on the top of the rear shoe. If it moves, you will also see the front shoe move away from that anchor. That is proof the parking brake cable is not fully-released.

Even if both shoes are resting against the anchor bolt, look next at the parking brake strut bar between the two shoes. There needs to be 1/8" gap between that bar and the front shoe, (green arrow). Push forward on that bar with your thumb at the rear shoe, by the orange arrow. The bar should move easily against the pressure of the anti-rattle spring. If that is tight with no free play, it is because the sticking parking brake cable is holding the lever attached to the top of the rear shoe partially-applied, or pulled forward. The self adjuster will be ineffective if there is no free-play in that strut bar.

For drum brakes that seem to apply by themselves, or fail to release properly, there are six "lands" on the backing plate that must be inspected. Those are the raised surfaces the shoes ride on, (three for each shoe). High-temperature brake grease must be applied to those spots during routine brake service. When it is not used, grooves can form on those lands, then the shoe frames can catch on them. A shoe may not apply properly, but more commonly, it will get stuck and won't release. GM has had a real big problem with this since the 1970's. Chrysler uses a version of the same brake, but there are three bent-over tabs on both sides of each shoe to increase the wear surface and reduce this problem. Those tabs are not shown in this drawing. I found a better drawing. The three purple arrows in the third drawing show those lands on the trailing shoe.

One last thing I should mention is with the wrong drum, one thing we forget to consider is the "labyrinth" seal. The yellow arrow in the fourth photo is pointing to it. There is a lip formed on the outer circumference of the backing plate that fits into this groove around the drum. Its purpose is to reduce entry of dirt and water. With the wrong drum, the backing plate might rub on the drum in that area. I suspect you would have heard that, but it is worth mentioning for others who might be researching this problem. It is also common for rust to build up on the drum and cause a grinding sound, but that typically wears away rather quickly, and is soon forgotten.

Images (Click to make bigger)

Wednesday, March 31st, 2021 AT 10:28 AM