Hi,

As far as the tool you are using, I'm not familiar with it. Have you tried clearing the saved code to see if it can be deleted?

The noise has me a bit concerned. Have you checked suspension and steering components? I'm worried it could be a ball joint or one of the control arm bushings.

Here are directions for testing a ball joint. The attached pics correlate with the directions.

________________________________________

2002 Pontiac Grand Prix V6-3.8L SC VIN 1

Ball Joint Inspection

Vehicle Steering and Suspension Suspension Testing and Inspection Component Tests and General Diagnostics Ball Joint Inspection

BALL JOINT INSPECTION

Ball Joint Inspection

Tools Required

- J 8001 Dial Indicator

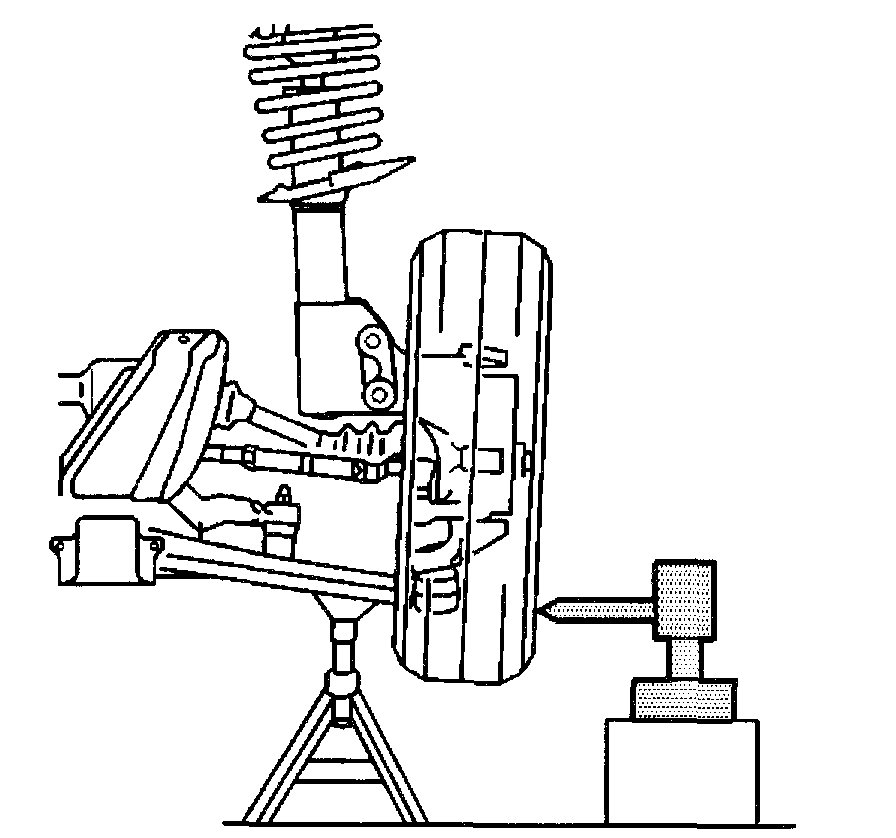

pic 1

Important:

The vehicle must rest on a level surface.

The vehicle must be stable. Do not rock the vehicle on the jack stands.

1. Raise and support the vehicle with safety stands. Refer to Vehicle Lifting.

2. Support the lower control arm with a jack stand, as far outboard as possible, near the lower ball joint.

3. Wipe the ball joint clean. Check the seals for cuts or tears.

Important: If a seal is cut or torn, replace the lower control arm.

4. Check the wheel bearings for looseness. If looseness in the wheel bearings is present, refer to Wheel Bearings Diagnosis.

5. Check the ball joint for horizontal looseness.

5.1. Position the J8001 against the lowest outboard point on the wheel rim.

5.2. Rock the wheel in and out while reading the dial indicator. This shows horizontal looseness in the lower ball joint.

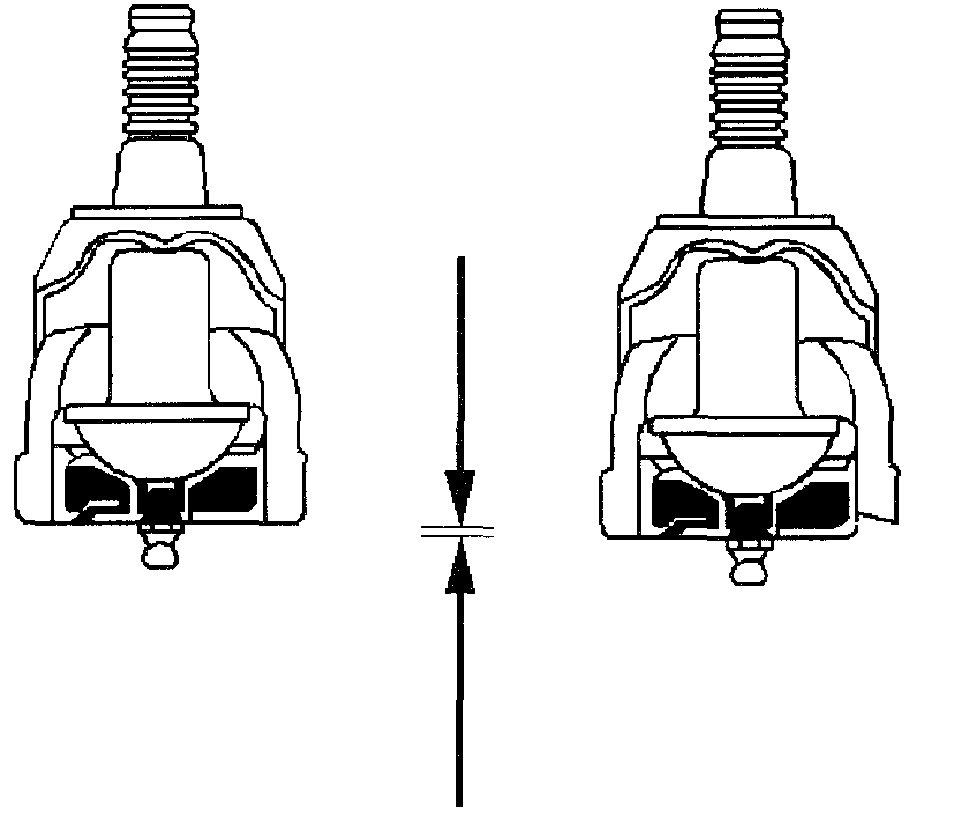

Pic 2

5.3. The dial indicator reading should be no more than 3.18 mm (0.125 inch). If the reading is too high, check the lower ball joint for vertical looseness.

6. Check the lower ball joint for wear and for vertical looseness using the following procedure:

6.1. Inspect by sight the lower ball joint for wear. The position of the housing into which the grease fitting is threaded indicates wear. This round housing projects 1.27 mm (0.050 inch) beyond the surface of the lower ball joint cover on a new ball joint. Under normal wear, the surface of the lower ball joint housing retreats inward very slowly.

6.2. First observe, then scrape a scale, a screwdriver, or a fingernail across the cover. If the round housing is flush with or inside of the cover surface, replace the lower control arm.

6.3. Pry between the lower control arm and the steering knuckle while reading the dial indicator. This shows vertical looseness in the ball joint. The lower ball joint is not preloaded and may show some looseness.

6.4. If the dial indicator reading is more than 3.18 mm (0.125 inch), replace the lower control arm.

______________________________

Make sure to check in all the steering components. I'm most worried if it is a ball joint, so check that. If you don't have the tools listed, simply place a jack under the lower control arm and safely lift that wheel. Put your hands at 12 and 6 o'clock and make sure there is no play.

______________________________

Joe

Images (Click to make bigger)

Sunday, July 19th, 2020 AT 3:21 PM