Hi Stuxnet97,

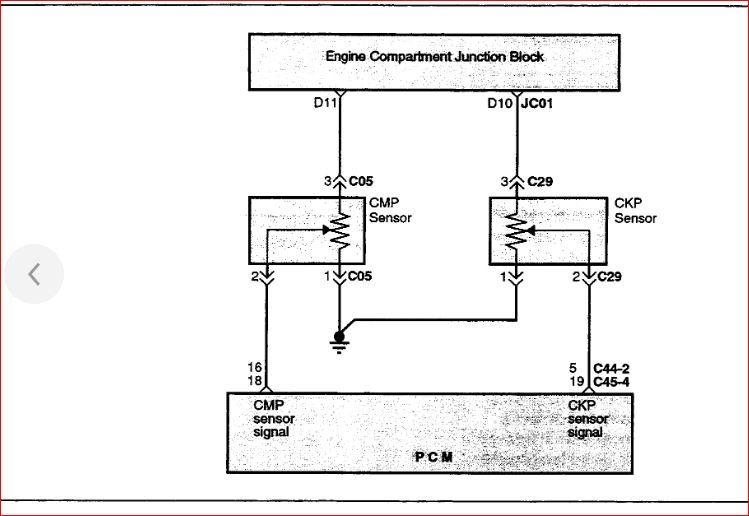

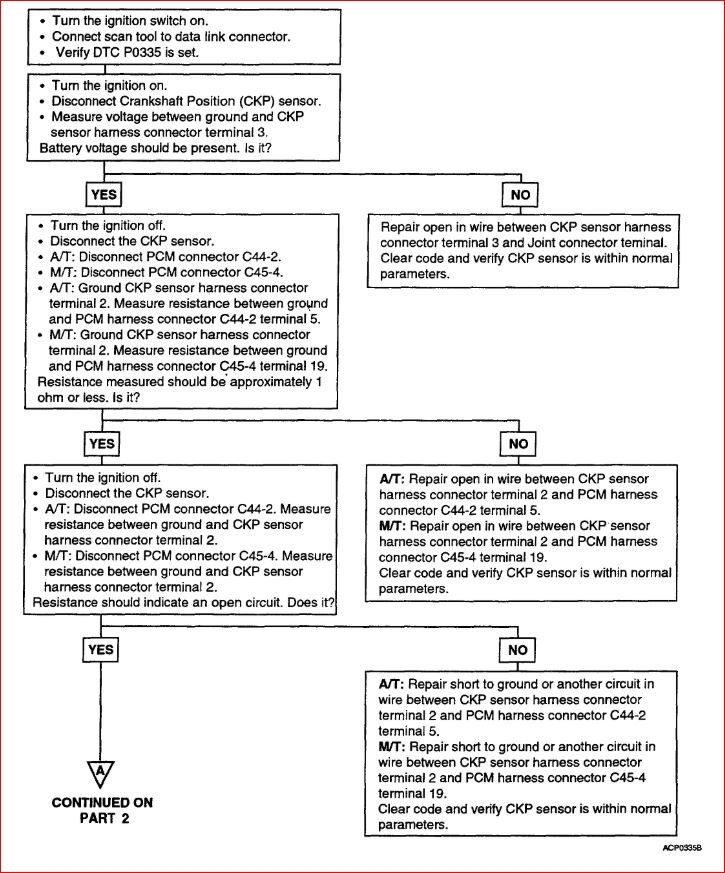

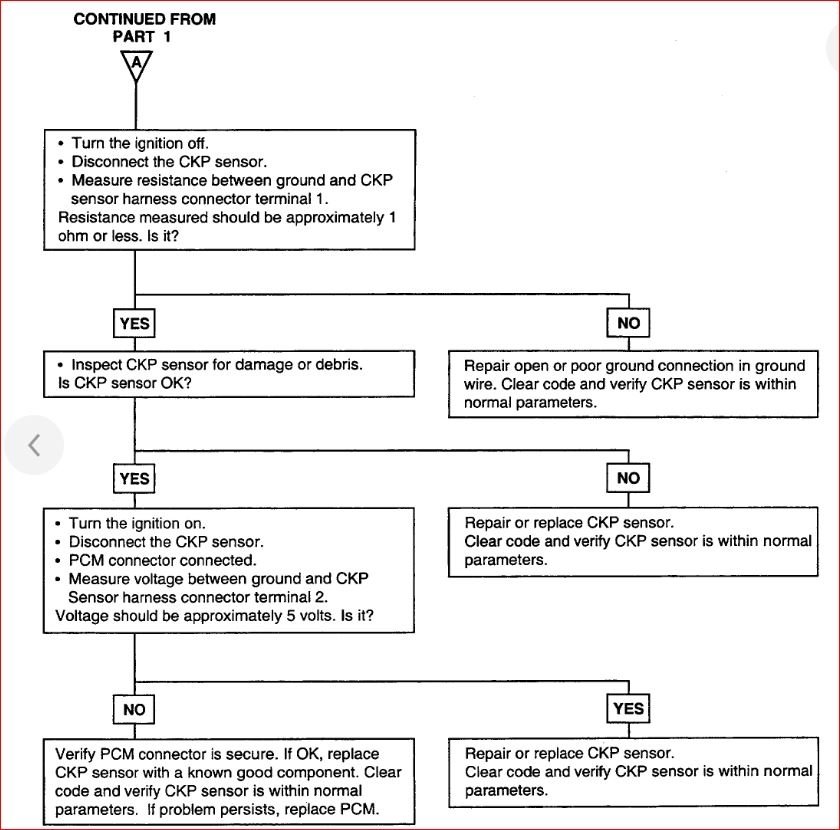

I attached the code description and diagram for this code. However, it appears you don't need that.

Assuming that the engine starts once you replace the sensor, there are a couple of things that would cause repeated failures. First, if there is excessive heat as you mentioned it will metal the sensor. I would suggest using an infrared temp meter to check the temp on the sensor and crank pulley while the engine is running. You mentioned that the first time you replaced the sensor that it was ruined and had to wait for it to cool down. Am I reading that correctly? If so, this is most likely your issue. You could have a bearing on the crankshaft going bad and it is getting excessively hot which translate that heat to the surrounding components including your sensor. This is why you need to measure the temp with the laser meter.

Second, is if there is metal or debris getting on the sensor. This will cause poor readings to the PCM and it will require replacement. Then when you replace it and it gets "dirty" it will fail again. You can tell this by comparing the sensor to the new one. See if it looks dirty and if so, you could try cleaning it with an electric parts cleaner. Don't spray it with brake clean as this has chlorine in it and can damage the sensor.

Lastly, if the crank wheel has an issue but this is least likely according to your symptoms. However, if the crank wheel has a crack in it, it will prevent a start but again, replacing just the sensor should not make a change.

https://www.2carpros.com/articles/how-to-use-an-infrared-temperature-meter

Let me know what you find and we can go from there. Thanks

Images (Click to make bigger)

Sunday, May 26th, 2019 AT 10:22 AM