Hi,

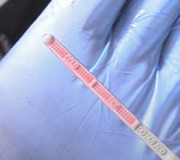

This code is specific to the TCC. Since it is the only code, I suspect either the actuator is bad or there is a bad o-ring at some point allowing pressure by bypass. The best advice I can give you is to check the TCC unit. I hope you understand that there are a few different things that can cause the code. I don't want you to replace parts just to find it didn't fix the problem. Testing does require special scanner. The solenoid in located in the transmission valve body. If you look at pic 1, I attached a flow chart for testing. Pic 2 shows the TCC solenoid.

_______________________________

Pic 3 is a schematic of the system related to the TCC. Here is info related to the code:

_______________________

NO TCC

When TCC is commanded On, the comparison of engine speed to turbine speed is monitored to assure TCC is On. When TCC is On the engine speed and turbine speed are equal. TCC is applied by grounding circuit 422.

DTC PARAMETERS

DTC 25 is set when the PCM has detected the following conditions for more than 7.5 seconds twice per ignition cycle.

Trans oil temperature above 20°C (68°F).

Gear selected is 2nd, 3rd, or 4th.

No engine or turbine speed codes or signal noise.

Engine speed is greater than 908 rpm.

Turbine speed is greater than 224 rpm.

TCC has been commanded on for more than five seconds and there has been no gear change.

Speed difference across torque converter is greater than 280 rpm.

TEST DESCRIPTION

Numbered steps below refer to numbered steps on chart.

1. Check for diagnostic trouble codes/information flags 21, 71, 72, 73, 74, 75, 76, 77, 78, 79, 81, 87, 88, 93, 97, 98, or 99. They must be eliminated first as a possible cause of DTC 25.

2. Check actuator operation. Use actuator quick check. The actuator quick test will Pulse Width Modulate (PWM) the actuators at a set rate. Listen and compare the noise of TCC gear actuator to that of other actuators. The noise of all should be similar.

3. Other possibilities for DTC 25 to set:

Internal leakage in the TCC apply circuit.

Possible low line pressure.

Converter charge valve stuck causing TCC apply pressure to be exhausted to lube.

Converter limiting valve stuck open.

Missing or damaged torque converter-input shaft O-ring.

DIAGNOSTIC AIDS

When the PCM detects a fault in the circuit (open, ground, short), the PCM will open the circuit internally to protect the circuit.

This DTC may be caused by a poor electrical connection at either the PCM, actuator connector plate or Underhood Junction Block (UHJB) terminals. Wiggling connectors while performing an actuator quick test may help isolate the problem area.

Due to the clutch priority valve, this DTC will be set when 2nd, 3rd or 4th gear is determined to be stuck on.

TCC Apply:

Engine temperature above 20°C (68°F).

Vehicle speed above 26 km/h (16 mph).

Transaxle temperature above a given value in relation to intake air temperature sensor (IAT) value.

TCC Release:

Low engine speed down shift (i.E, light throttle, or steady) throttle with load increase.

Low end of 3rd gear speed range, brake on = TCC off.

Fast deceleration, i.E, brake lock on ice = TCC off, gear = neutral.

____________________________

I wish I could offer more. Also, I'm not sure where you are located. Are you having trouble finding a gasket?

Let me know.

Joe

Images (Click to make bigger)

Wednesday, February 19th, 2020 AT 8:23 PM