Doesn't matter. Running the engine just gives you power assist which makes the pedal easier to push.

I'm glad you asked though because there's one huge potential pitfall to avoid. During normal driving, you never push the brake pedal more than roughly halfway to the floor. As such, the two pistons in the master cylinder never travel through the lower halves of their bores. After about a year, crud and corrosion begins to build up in those unused areas. Later, when you push the brake pedal to the floor, the rubber lip seals get run over that crud and can rip them. That causes a slowly sinking brake pedal, and it commonly takes about three days for that to show up. You can usually buy master cylinder rebuild kits, but it's almost always less expensive to buy a professionally rebuilt master cylinder with a warranty.

This damage can occur when pumping the brake pedal to run the caliper pistons out to adjust them, like you're asking about, when a brake hose pops, and even the instructions in some service manuals tell you to push the pedal to the floor when bleeding the hydraulic system with a helper. (Doing so can cause a whole different hard-to-diagnose problem on GM vehicles). The bottom line is never push the pedal over halfway to the floor. Those half strokes are more than enough to run the caliper pistons out.

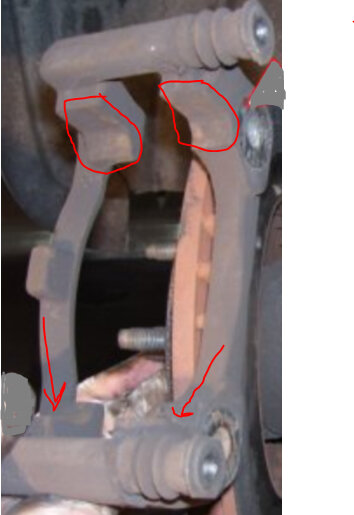

As a point of interest, that crud can build up behind the caliper pistons too and cause trouble. I use a flat-blade screwdriver to pry the pistons into the housings first, before I remove the calipers from their mounts. If they go in smoothly, they aren't going to cause a problem. If you have to remove the caliper, then resort to using a c-clamp, which I never approve of, you're driving the piston over that crud or you're driving a rust ring on the piston under the rubber square-cut seal. Either one will cause brake dragging and overheating.

Good practice is to run a flat file over the piston where it contacts the backing plate of the inner pad, and over the fingers of the caliper where they contact the outer pad. The goal is not to shine them up. It's just to remove any high spots of rust or dirt that will interfere with the pads sitting squarely. That dirt can help a vibration to occur that we hear as a squeal. Use a little high-temperature brake grease on those pad backing plate contact points. Brake pads are going to vibrate and cause a squeal. That grease lets them vibrate smoothly rather than transmitting the noise to the caliper where it will get amplified.

Wednesday, April 24th, 2024 AT 7:54 PM