I took it to reputable shop where they replaced the freeze plugs and learned that the no start was due to faulty distributor which was replaced with new cap and rotor.

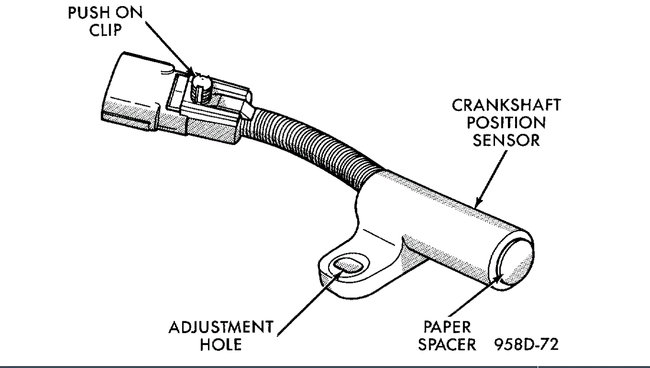

Now, after warming up it will miss and last week was throwing a code P1391. So I thought perhaps the new sensor was faulty and replaced it with another new sensor. Air gap is properly set using sensor's felt spacer. The car will run perfectly with no misses after the first start of the day until I shut it off and then start again and drive where it misses badly at all speeds; engine light comes on also at this time.

Unfortunately, auto stores are not checking codes (Covid), and I have to wait until Monday to see what code is related to this last check engine light.

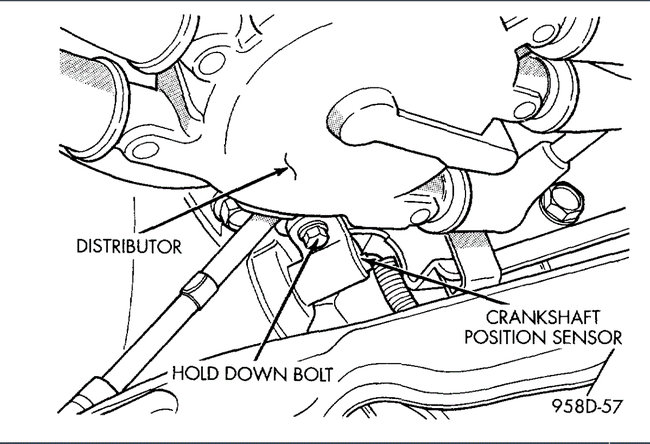

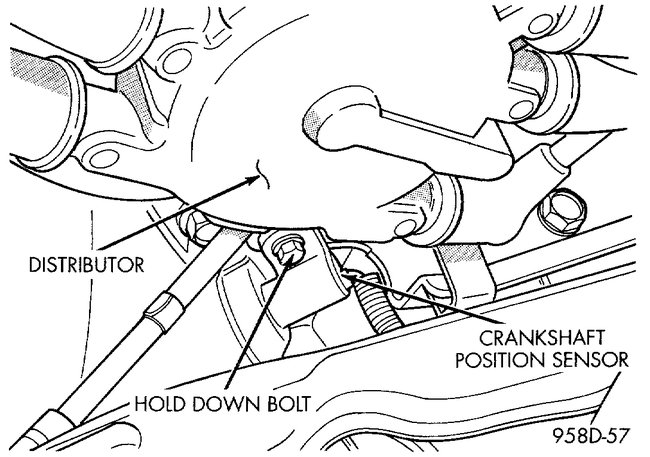

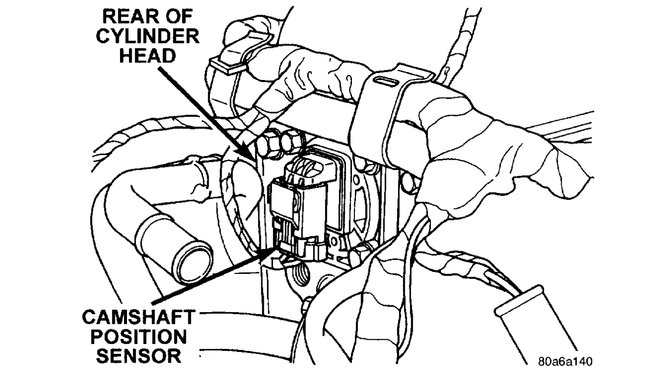

My questions: I read where cap and rotor could be faulty on new distributor; would that throw a P1391 though? Since a 1391 refers to crank and cam, what are the chances my cam sensors are faulty in my new distributor? All sources tell me the cam sensors are in the distributor on my 2.5L, V6. The shop did have to remove and replace the trans-axle to repair freeze plugs which includes detaching from flywheel. What are the chances some interference with flywheel during this remove and replace is causing this problem?

The most significant fact here is that it runs like it's brand new when it's cool, but once heated (expansion), it misses horribly. Any help is greatly appreciated.

Saturday, August 1st, 2020 AT 4:03 PM