4.6L V8 - VIN [W] -1995 Mercury Grand Marquis GS

Page 1 of 3

TIMING CHAINS

CAUTION:DO NOT rotate engine with timing chain removed. Damage to valve/piston may result.

Removal (SOHC)

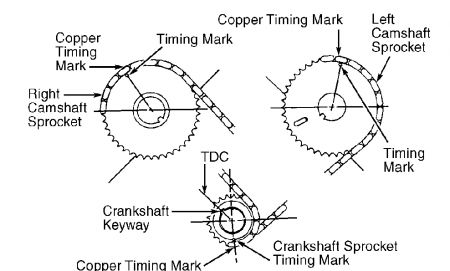

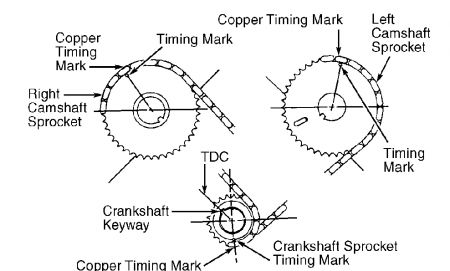

1.Remove valve covers. See VALVE COVERS . Remove front cover. See FRONT COVER . Remove crankshaft position sensor pulse wheel from crankshaft. 2.Rotate crankshaft until No. 1 piston is at TDC. This positions crankshaft keyway 45 degrees from vertical position. See Fig. 10 . Camshaft keyways will point toward crankshaft.

CAUTION:Mark component location for reassembly reference. Components must be installed in original locations.

3.Install Camshaft Positioner (T92P-6256-A) on flat area near rear of camshaft. See Fig. 13 . Remove retaining bolts, right chain tensioner, right tensioner arm and right chain guide. Refer to Fig. 14 . 4.Remove right timing chain and crankshaft sprocket. Note direction of sprocket for installation reference. If necessary for clearance, remove retaining bolt, washer, camshaft sprocket and spacer.

Fig. 10: Aligning Camshaft & Crankshaft Timing Marks

Courtesy of FORD MOTOR CO.

Fig. 11: Installing Crankshaft Sprocket

Courtesy of FORD MOTOR CO.

Fig. 12: Compressing Timing Chain Tensioner Plunger Courtesy of FORD MOTOR CO.

Fig. 13: Installing Camshaft Positioner

Courtesy of FORD MOTOR CO.

Fig. 14: Exploded View Of Timing Chain & Components

Courtesy of FORD MOTOR CO.

CAUTION:DO NOT rotate engine with timing chain(s) removed. Damage to valve/piston may result.

5.Remove retaining bolts, left chain tensioner, left tensioner arm and left chain guide. See Fig. 14 . Remove left timing chain and crankshaft sprocket. Note direction of sprocket for installation reference. If necessary for clearance, remove retaining bolt, washer, camshaft sprocket and spacer.

Inspection

2/6/2009

4.6L V8 - VIN [W] -1995 Mercury Grand Marquis GS

Page 2 of 3

Inspect components for damage. Inspect friction surfaces on tensioner arms and chain guides for wear. Replace components if necessary. If tensioner arms or guides are worn or damaged, remove and clean oil pan. Also, replace oil pump screen cover and tube.

CAUTION:If components are replaced due to damage, ensure crankshaft is rotated so pistons are below deck surface (crankshaft keyway at 90 degrees) to prevent contact with valves. See Fig. 6 . Ensure camshaft positioner is installed on camshaft(s) before installing timing chain(s).

Installation

1.Install spacers, camshaft sprockets and retaining bolts. Ensure components are installed in original locations. Tighten bolts to specification. See TORQUE SPECIFICATIONS . 2.Install Camshaft Positioner (T92P-6256-A) on flat areas of camshaft if not previously installed. See Fig. 13 .

CAUTION:Install crankshaft sprocket halves with hubs facing each other. See Fig. 11 .

3.Install crankshaft sprocket for left timing chain. If copper links are not visible on timing chain, fold timing chain in half and mark each end link for timing purposes. See Fig. 11 . These links will be referred to as copper links when installing. 4.Ensure No. 1 piston is at TDC. This positions crankshaft key-way 45 degrees from vertical position. See Fig. 6 . Crankshaft keyway will point toward camshaft. 5.Install left timing chain on camshaft and crankshaft sprockets so copper link aligns with timing mark on sprockets. See Fig. 11 . Install crankshaft sprocket for right timing chain. Ensure sprocket is properly installed. See Fig. 12 . 6.Install right timing chain on camshaft and crankshaft sprockets so Copper link aligns with timing mark on sprockets. See Fig. 11 . Install Crankshaft Positioner (T93P-6256-A), to prevent crankshaft movement. Lubricate tensioner arms with engine oil. Install tensioner arms. Install chain guides. 7.Chain tensioners must be bled down so tensioner plunger is compressed in housing before installing. Place chain tensioner in soft-jawed vise. Using small pick, hold ratchet lock mechanism away from ratchet stem. See Fig. 12 . Slowly close vise to depress tensioner plunger. 8.When tensioner plunger is compressed in housing, continue to hold ratchet lock mechanism and install lock pin in hole on tensioner housing. Ensure ratchet stem is even with tensioner housing before installing lock pin. See Fig. 12 . 9.Using a "C" clamp or suitable tool, remove all slack from the timing chain by applying pressure to the tensioner arm. While holding pressure on arm, install both chain tensioners and retaining bolts on cylinder block. Tighten retaining bolts to specification. See TORQUE SPECIFICATIONS .. 10.Remove lock pins from both chain tensioners. Ensure all timing marks align. See Fig. 10 . To check accuracy of valve timing, remove No. 1 spark plug. Using a dial indicator, check for maximum intake valve lift. Maximum intake valve lift should occur at 114 degrees after TDC. 11.To install remaining components, reverse removal procedure. Before installing valve cover, apply silicone sealant at front cover-to-cylinder block areas.

2/6/2009

4.6L V8 - VIN [W] -1995 Mercury Grand Marquis GS

Page 3 of 3

12.When installing fuel lines, fit new fuel resistant "O" rings (Brown) on fuel lines. Lightly coat "O" rings with clean engine oil before installing. Clean fittings, and replace garter spring (if necessary).

2/6/2009

Friday, February 6th, 2009 AT 6:14 PM