P0106 - Manifold Absolute Pressure/Barometric Pressure Circuit Range/Performance Problem

Thank you for providing that information. This could indeed be caused by a defective sensor, ... However, ... If one of us were to tell someone to buy one and replace it, you can be sure there would be swear words associated with our names when it does not solve the problem. If you read through some of the other posts here, you will see the biggest majority of people asking for help with a sensor-related problem already tried a new sensor, and now they are here when it did not solve the problem. That is what I am trying to help you avoid.

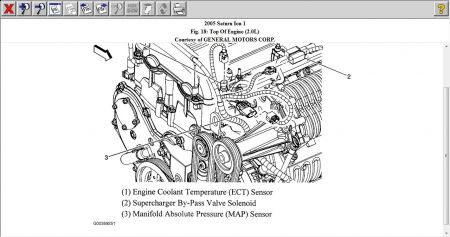

As you can see by this code definition, as with all the others, it does not say to replace anything. What it means is the readings from that sensor do not agree with some of the other things the Engine Computer compares it to. For example, manifold vacuum goes real low during periods of hard acceleration, but what if the throttle position sensor is reporting you are at idle at that time? The typical suspect would be a cracked vacuum hose going to the map sensor. To prevent that from becoming a problem, most map sensors now are plugged right into the intake manifold and they do not use a separate hose, but the readings can still be adversely affected by some other vacuum leak.

To add another exciting chapter to this wondrous story, GM developed one of their more common map sensors for use in the mid 1980's, and they had a really huge problem with them, ... So they sold them to Chrysler, which also had a very high failure rate. GM redesigned them, then had almost no problems at all. Eventually Chrysler used the same design and also had almost no failures. Since then, map sensor failures are very rare. That is why we look at wiring problems first, before we spend our customers' money on parts. Chrysler is the only manufacturer that has never needed or used a mass air flow sensor for fuel metering calculations. It is all done with the map sensor, which is also used to measure barometric pressure before the engine starts running. GM, and most other manufacturers use the mass air flow sensor for their main fuel calculation, and the map sensor is only used as a back-up strategy when needed, and for measuring barometric pressure while you are driving. In fact, a lot of manufacturers call it a "barometric pressure sensor". What that means for us is the symptoms from a failing map sensor vary by car brand. The clue to a failed map sensor on an older Chrysler product is you could keep the engine running as long as the accelerator pedal was moving. Direction and rate of change did not matter; it just had to be moving. That surprised a lot of owners who had their vehicles brought in on a tow truck, then they saw us hop in and drive them into the shop. The map sensor is far less important on other car brands, so often you will just have the elusive fault code, but the engine runs fine.

If you replace your map sensor and the fault code does not set again, we will all be quite happy, but to be sure, pop the old one back in and see what happens. If the fault code sets again, that is pretty good assurance the sensor really was bad. There is a fairly good chance the code will not set again and the old sensor will keep on working. When that happens, it is usually due to a very light film of corrosion that formed on the connector terminals. The scratching action of pulling the connector off and on multiple times creates a clean and shiny area for the mating terminals to make better contact. I used to see that at least weekly when repairing TV's with plug-in modules. Walk across the floor and the brightness would flicker, or one color would disappear. Unplug the module, plug it back in, problem solved! Of course the complete repair was more involved to include sanding the terminals and tightening them, but if the do-it-yourselfer owner bought a replacement module, that would solve the problem for a few months, but it did not address all of the cause. He would be angry for incorrectly assuming the modules kept on failing.

To finish my history lesson on map sensors, the original design used a piezoelectric crystal, similar to that used in a low-end phonograph cartridge. It develops a voltage when pressure is applied to it, then the circuitry inside the sensor amplifies it so the Engine Computer can read it. The problem was caused when people filled the gas tank, then kept on stuffing in more and more gas, then drove a short distance and parked the car, on a very hot day. Every single one of those variables had to be in play. The cold gas would warm up and expand, then the fumes would get pushed through the vapor recovery hose and charcoal canister, into the intake manifold where it found its way to the map sensor. Those fumes ate away the protective jelly the circuitry was sealed in, and they attacked the rubber diaphragm. If it was a cold day, or you immediately drove a good fifty miles or more, or you stopped filling the tank when the pump kicked out, and just finished out the dollar, those fumes did not cause a problem.

The newer design uses a "strain gauge". That is a very long, very thin wire wrapped around a plastic core, then that core is hooked to the rubber diaphragm. When the wire gets tugged on, its length and its diameter change very slightly, but enough that when the circuitry amplifies the change in resistance, it produces a usable signal. While no one actually does this, both designs are so sensitive, they could be used to measure engine speed. Each time a piston takes a gulp of air, there is a momentary tiny increase in vacuum. These sensors are able to detect those slight vacuum changes and count the number of intake events that occur in a given amount of time.

For my parting thought of value, if you have access to a scanner, you might consider watching the readings from the map sensor under a variety of conditions, before you replace it, then compare them to those from the new sensor. Sometimes we can learn a clue to look for the next time we run into this. That clue can even be that the readings from the defective sensor and the new one look exactly the same. Knowing that could give you more confidence when ordering a replacement for the next car.

Please keep us updated on your progress.

Wednesday, June 20th, 2018 AT 7:49 PM