Hello.. thnaks for the donation ..much appreciated

Check all fuse's and relay then do the following tests .. also check for suspension fault codes

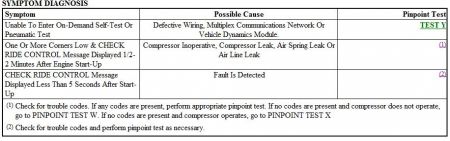

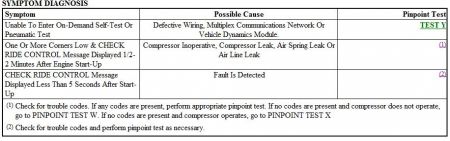

TEST W - ONE OR MORE CORNERS LOW, NO CODES RETRIEVED & COMPRESSOR INOPERATIVE

Check Relay Connector

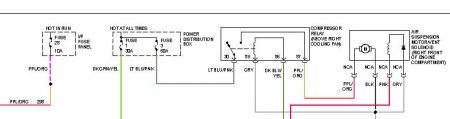

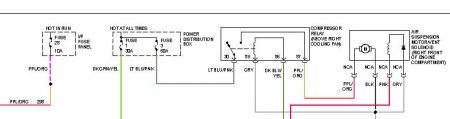

Disconnect air compressor relay 4-pin connector. Relay is located front center of engine compartment. Check connector for corrosion, bent pins and damaged wires. Repair as necessary and repeat ON-DEMAND SELF-TEST and PNEUMATIC TEST. If connector is okay, go to next step.

Check Compressor Operation

Connect a jumper wire between Light Blue/Pink wire and Purple/Orange wire at relay connector. If compressor does not run, remove jumper wire and go to next step. If compressor runs, go to PINPOINT TEST Q and then to PINPOINT TEST R.

Check For Battery Voltage

Measure voltage between ground and Light Blue/Pink wire at relay connector. If battery voltage is present, go to next step. If battery voltage is not present, go to step 7).

Check Circuit Continuity

Disconnect air compressor connector. See Fig. 1 . Check continuity of Purple/Orange wire between relay connector and air compressor connector. If continuity exists, go to next step. If continuity does not exist, repair open in Purple/Orange wire. Repeat ON-DEMAND SELF-TEST and PNEUMATIC TEST.

Check Ground Circuit

Measure resistance between ground and Black wire at air compressor connector. If resistance is less than 3 ohms, go to next step. If resistance is 3 ohms or more, repair open in Black wire between ground and compressor connector. Repeat ON-DEMAND SELF-TEST and PNEUMATIC TEST.

Check Compressor Operation

Connect a jumper wire between positive battery terminal and Purple/Orange wire at air compressor connector. Connect another jumper wire between negative battery terminal and Black wire at air compressor connector. If compressor runs, no problem is indicated at this time. Repeat ON-DEMAND SELF-TEST and PNEUMATIC TEST. If compressor does not run, replace compressor. Repeat ON-DEMAND SELF-TEST and PNEUMATIC TEST.

Check Compressor Fuse

Remove and inspect No. 3 (60-amp) fuse from power distribution center, on left side of engine compartment. If fuse is okay, repair open Light Blue/Pink wire between power distribution center and air compressor relay. Repeat ON-DEMAND SELF-TEST and PNEUMATIC TEST. If fuse is blown, go to next step.

Check Circuit No. 417

Disconnect air compressor connector. See Fig. 1 . Measure resistance between ground and Purple/Orange wire at air compressor connector. If resistance is 10,000 ohms or more, go to next step. If resistance is less than 10,000 ohms, repair short to ground in Purple/Orange wire between power distribution center and air compressor connector. Replace fuse and repeat ON-DEMAND SELF-TEST and PNEUMATIC TEST.

Check Circuit No. 430

Measure resistance between ground and Gray wire at air compressor connector. If resistance is less than 3 ohms, go to next step. If resistance is 3 ohms or more, repair open in Gray wire between ground and air compressor connector. Repeat ON-DEMAND SELF-TEST and PNEUMATIC TEST.

Check Compressor Operation

Connect a jumper wire between positive battery terminal and Purple/Orange wire at air compressor connector. Connect another jumper wire between negative battery terminal and Black wire at air compressor connector. If compressor runs, no problem is indicated at this time. Repeat ON-DEMAND SELF-TEST and PNEUMATIC TEST. If compressor does not run, replace compressor. Repeat ON-DEMAND SELF-TEST and PNEUMATIC TEST.

TEST X - ONE OR MORE CORNERS LOW, NO CODES RETRIEVED & COMPRESSOR INOPERATIVE

Check For Pinched Air Line

Disconnect air line from air compressor and air spring solenoid. Connect a vacuum pump to one end of disconnected line. Apply vacuum. If vacuum does not hold, reconnect line and go to next step. If vacuum holds, service pinched or obstructed air line as necessary. Repeat ON-DEMAND SELF-TEST and PNEUMATIC TEST.

Check For Leaking Air Line

Reinstall one end of air line in a known good air spring. Connect a vacuum pump to other end of air line. Apply vacuum. If vacuum holds, go to next step. If vacuum does not hold, replace air line. Repeat ON-DEMAND SELF-TEST and PNEUMATIC TEST

Check Solenoid Function

Hook-up New Generation Star (NGS) tester. See EQUIPMENT HOOK-UP under TESTING & DIAGNOSIS. Rotate dial (on scan tester) to menu item DIAGNOSTIC DATA LINK, and press trigger to select. Select VDM-VEHICLE DYNAMICS MODULE. Select ACTIVE COMMAND MODES. Select AIR SUSPENSION CONTROLS. Select PIDs. Select ASLFSOL, ASRFSOL, ASRRSOL or ASLRSOL. Press start (button 3). Command SOLENOID: ON. Using compressed shop air, attempt to inflate air spring. If air flows into spring, go to next step. If air does not flow into spring, replace solenoid. Repeat ON-DEMAND SELF-TEST and PNEUMATIC TEST

Check For Maximum Pressure

Install pressure gauge in air compressor drier air line port. With solenoid still on, command COMPRESSOR: ON and observe pressure gauge. If pressure reaches a minimum of 150 psi, go to next step. If pressure does not reach 150 psi, replace compressor assembly. Repeat ON-DEMAND SELF-TEST and PNEUMATIC TEST.

Check Holding Pressure

With air pressure at a minimum of 150 psi, command COMPRESSOR: OFF and observe pressure gauge. If pressure holds, no problem is indicated at this time. Repeat ON-DEMAND SELF-TEST and PNEUMATIC TEST. If pressure leaks down, replace compressor drier assembly. Repeat ON-DEMAND SELF-TEST and PNEUMATIC TEST.

Tuesday, November 13th, 2018 AT 6:13 PM

(Merged)