DTC P1259 - VTEC PRESSURE SWITCH & SOLENOID VALVE CIRCUIT

1 . Perform PCM reset procedure. Start engine and run at 3000 RPM with no loads and transmission in Park or Neutral until radiator fan comes on. Road test vehicle. Accelerate in 1st gear to an engine speed of more than 6000 RPM. Hold specified engine speed for at least 2 seconds. If DTC P1259 is not repeated during first road test, repeat road test 2 more times. If DTC P1259 is indicated, go to next step. If DTC P1259 is not indicated, problem is intermittent. System is okay at this time. Check for poor connections or loose wires between VTEC pressure switch, solenoid valve and PCM connectors. Repair as necessary.

2 . Turn ignition off. Disconnect VTEC pressure switch 2 -pin connector. Check for VTEC pressure switch continuity between switch terminals No. 1 (Blue/Black wire) and No. 2 (Brown/Black wire). If continuity exists, go to next step. If continuity does not exist, replace VTEC pressure switch.

3 . Turn ignition on. Check voltage between ground and VTEC pressure switch harness connector terminal No. 1 (Blue/Black wire). If about 12 volts exists, go to next step. If about 12 volts does not exist, check for an open or short in Blue/Black wire between VTEC pressure switch and PCM 31 -pin connector "C" terminal C15. If wire is okay, substitute a known-good PCM and recheck. If symptom or problem goes away, replace original PCM.

4 . Measure voltage between VTEC pressure switch harness connector terminals. If about 12 volts exists, go to next step. If about 12 volts does not exist, repair open in Black wire between VTEC pressure switch and ground connection G101, located at right side of engine, near VTEC pressure switch.

5 . Remove 10 -mm oil pressure inspection bolt located above thermo- stat housing and connect

an oil pressure gauge. Connect a tachometer. Start engine and warm to operating temperature. Because engine is running with no load, oil pressure must be checked within one minute. Check oil pressure at engine speeds of 1000, 3000 and 5000 RPM. If oil

pressure is less than 7 psi, go to next step. If oil pressure is 7 psi or more, go to step 11).

6 . Turn ignition off. Disconnect VTEC solenoid valve connector. Using a fused jumper wire, connect battery voltage to VTEC solenoid valve terminal. Start engine and check oil pressure at 5000 RPM. If oil pressure is more than 60 psi, go to next step. If oil pressure is not more than 60 psi, go to step 11).

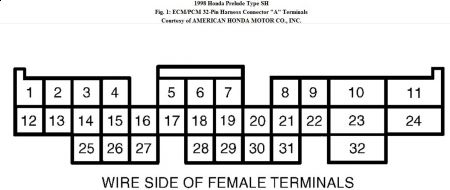

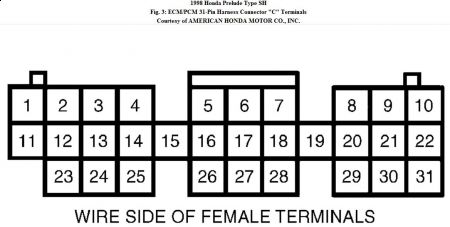

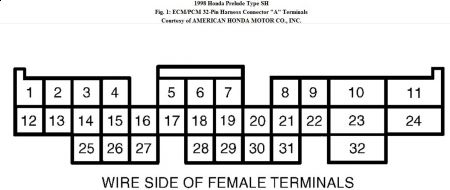

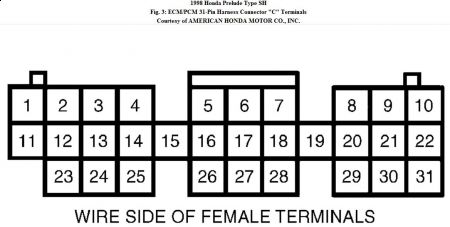

7 . Turn ignition off. Reconnect VTEC pressure switch connector. Start engine. With battery voltage connected to VTEC solenoid valve terminal, measure voltage between PCM 31 -pin connector "C" terminals C15 (Blue/Black wire) and PCM 32 -pin connector "A" terminal A10 (Black wire) or A23 (Black wire). See Fig. 1 and Fig. 3 . If about 12 volts exists at more than 5000 RPM, go to next step. If about 12 volts does not exist at more than 5000

RPM, replace VTEC pressure switch.

8 . Turn ignition off. Disconnect battery voltage from VTEC solenoid valve. Measure resistance between ground and VTEC solenoid valve terminal. If resistance is 14 -30 ohms, go to next step. If resistance is not 14- 30 ohms, replace VTEC solenoid valve.

9 . Check for continuity in Green/Yellow wire between VTEC solenoid valve harness connector terminal and PCM 32 -pin connector "A" terminal A8. See Fig. 1 . If continuity exists, go to next step. If continuity does not exist, repair open in Green/Yellow wire between VTEC solenoid valve and PCM.

10 . Check for continuity between ground and VTEC solenoid valve harness connector terminal. If continuity does not exist, substitute a known-good PCM and recheck. If symptom or problem goes away, replace original PCM. If continuity exists, repair short in Green/Yellow wire between VTEC solenoid valve and PCM.

11 . Remove VTEC solenoid valve assembly from cylinder head. Check VTEC solenoid valve filter/"O" ring and valve plunger for clogging. If filter/"O" ring is okay, go to next step. If filter/"O" ring is clogged, replace engine oil and oil filter. Repair or replace as necessary.

12 . Push VTEC solenoid valve plunger with finger and ensure normal movement. Repair or replace as necessary. If plunger movement is normal, ensure engine oil pressure is correct.

Wednesday, September 2nd, 2009 AT 3:11 PM