Here are the diagnostics for the trouble codes.

DTC P0134: A/F SENSOR (SENSOR 1) SIGNAL STUCK LEAN

1 . Check the A/F sensor (Sensor 1) in the exhaust pipe.

Is it loose?

YES - Reinstall the A/F sensor (Sensor 1)

NO - Go to step 2.

2 . Reset the ECM/PCM

3 . Start the engine. Hold the engine at 3,000 RPM with no load (in Park or neutral) until the radiator fan comes on, then let it idle for 2 minutes.

Is DTC P0134 indicated?

YES - Replace the A/F sensor (Sensor 1)

NO - Intermittent failure, system is OK at this time. Check for poor connections or loose terminals at the A/F sensor (Sensor 1) and the ECM/PCM.

DTC P1456: EVAP CONTROL SYSTEM LEAKAGE (FUEL TANK SYSTEM)

NOTE:

The fuel system is designed to allow specified maximum vacuum and pressure conditions. Do not deviate from the vacuum and pressure tests as indicated in these procedures. Excessive pressure/vacuum would damage the EVAP components or cause eventual fuel tank or system failure.

Special Tools Required

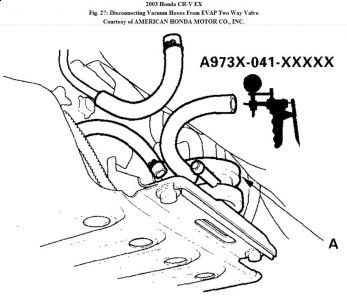

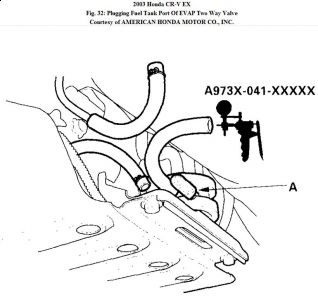

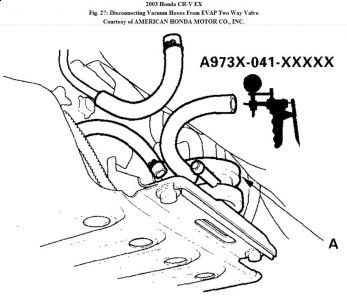

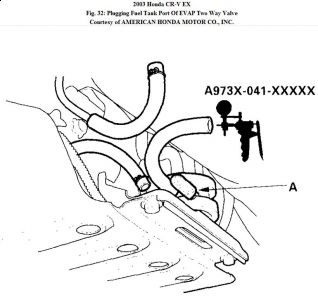

Vacuum pump/gauge, 0-30 in.Hg A973X-041-XXXXX

This is a two-trip code; once cleared, it cannot be reproduced in one trip. Also, certain specific driving and ambient conditions must occur before the ECM/PCM will complete the system checks. Additional test drives may still not meet the specific conditions needed to reproduce the code. If necessary, use the test drive procedures for setting the readiness code (see HOW TO SET READINESS CODES ).

Follow these troubleshooting procedures carefully to ensure the integrity of the system and to confirm the cause of the problem or code.

NOTE:

Fresh fuel has a higher volatility that will create greater pressure/vacuum. The optimum condition for testing is fresh fuel, and must be less than a full tank of fuel. If possible, to assist in leak detection, add 1 gallon of fresh fuel to the tank (as long as it will not fill the tank), just before starting these procedures.

Fuel Fill Cap Check

1 . Check the fuel fill cap (the cap must say "If not tightened 3 clicks check engine light may come on").

Is the correct fuel fill cap installed and properly tightened?

YES - Go to step 2.

NO - Replace or tighten the cap.

2 . Check the fuel fill cap seal and the fuel fill pipe mating surface.

Is the fuel fill cap seal missing or damaged, or is the fuel fill pipe damaged?

YES - Replace the fuel fill cap or the fuel fill pipe.

NO - Go to step 3.

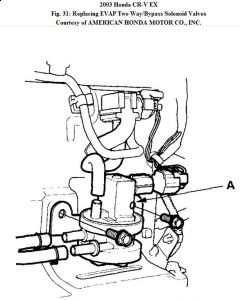

EVAP Bypass Solenoid Valve Test

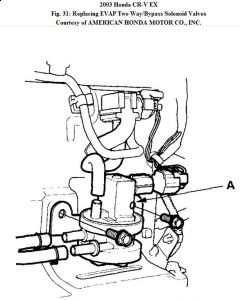

3 . Disconnect both vacuum hoses from the EVAP two way valve (A), and connect a vacuum pump to the canister port on the EVAP two way valve.

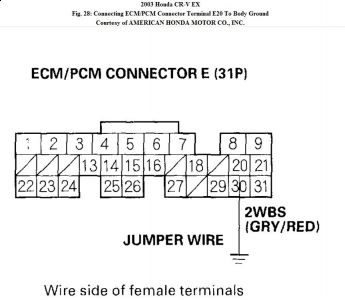

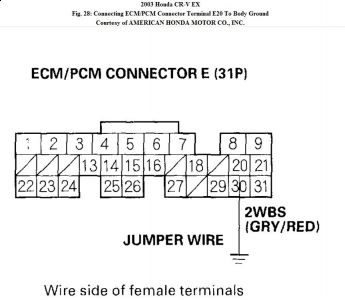

4 . Turn the EVAP bypass solenoid valve ON with the HDS, or connect ECM/PCM connector

terminal E20 to body ground with a jumper wire.

5 . Turn the ignition switch ON (II).

6 . Apply vacuum to the hose.

Does the valve hold vacuum?

YES - Go to step 7.

NO - Go to step 12.

7 . Turn the ignition switch OFF.

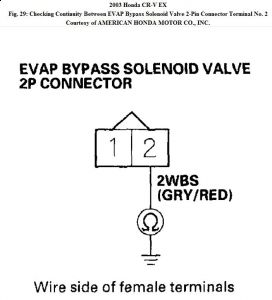

8 . Disconnect the EVAP bypass solenoid valve 2P connector.

9 . Remove the jumper wire from ECM/PCM connector E (31P), and turn the ignition switch ON (II).

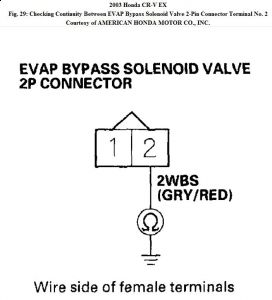

10 . Check for continuity between EVAP bypass solenoid valve 2P connector terminal No. 2 and body ground.

Is there continuity?

YES - Go to step 11.

NO - Repair open in the wire between the EVAP bypass solenoid valve and the ECM/PCM (E20).

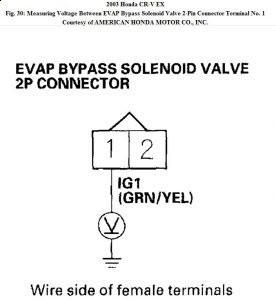

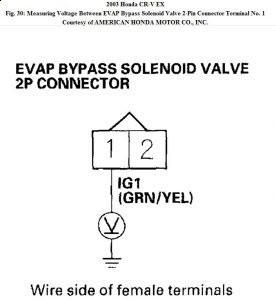

11 . Measure voltage between EVAP bypass solenoid valve 2P connector terminal No. 1 and body ground.

Is there battery voltage?

YES - Replace the EVAP two way/bypass solenoid valves (A).

NO - Repair open in the wire between the EVAP bypass solenoid valve and the No. 4 ACG (10A) fuse.

12 . Plug the fuel tank port (A) of the EVAP two way valve.

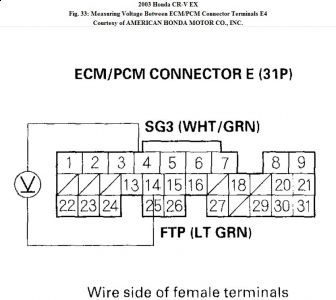

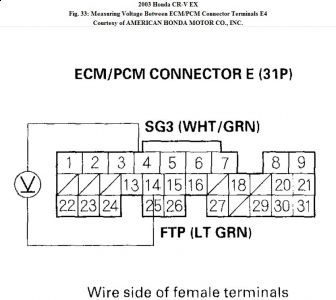

13 . While monitoring FTP sensor voltage with the HDS, or measuring voltage between ECM/PCM connector terminals E4 and E14, slowly pump the vacuum pump once, or until the voltage drops to about 1.5 V.

Does the voltage drop to 1.5 V and hold for at least 20 seconds?

YES - The EVAP bypass solenoid valve/EVAP two way valve is OK. Go to step 14.

NO - Repair the leakage from the EVAP bypass solenoid valve, EVAP two way valve, or FTP sensor.

Vacuum Hoses and Connections Test

14 . Perform the fuel tank vapor control valve test (see Fuel Tank Vapor Control Valve Test ).

Is the fuel tank vapor control valve OK?

YES - Go to step 15.

NO - Replace the fuel tank vapor control valve.

15 . Tighten the fuel cap 3 clicks.

16 . Start the engine, and let it idle for 5 minutes.

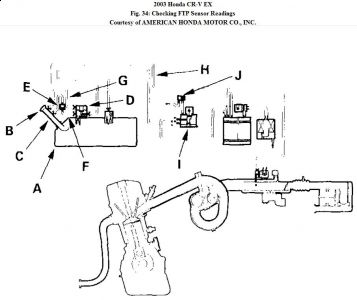

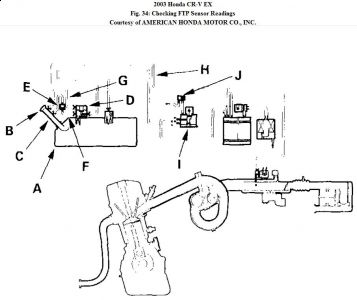

17 . Check the FTP sensor readings.

Is the reading above 0.5 kPa of (4 mmHg, 0.16 in.Hg, 2.8 V) pressure?

YES - Update the ECM/PCM if it does not have the latest software, or substitute a known-good ECM/PCM, then recheck (see ECM/PCM UPDATING AND SUBSTITUTION FOR TESTING ). If the symptom/indication goes away with a known-good ECM/PCM, replace the original ECM/PCM.

NO - Check the following parts for leaks:

"� Fuel tank (A)

"� Fuel fill cap (B)

"� Fuel fill pipe (C)

"� Fuel tank vapor control valve (D)

"� Fuel tank vapor recirculation valve (E)

"� Fuel tank vapor recirculation tube (F)

"� Fuel tank vapor signal tube (G)

"� Fuel tank vapor control vent tube (H)

"� Two way valve (I)

"� FTP sensor (J)

"� Fuel tank unit base gasket

Repair or replace any leaking parts.

Monday, February 8th, 2010 AT 10:49 AM