Hi x-ray-cat,

To be accurate, you would need a special tool to measure the tension.

BELT TENSION GAUGE METHOD

Inspection

1 . Remove the P/S reservoir from the bracket, and set it aside.

2 . Attach the belt tension gauge to the belt, and measure the tension of the belt. Follow the

gauge manufacturer's instructions. If the belt is worn or damaged, replace it.

NOTE: Remove the belt tension gauge carefully to avoid hitting the gauge reset lever.

Tension:

Used Belt: 390 - 540 N (40 - 55 kgf, 88 - 121 lbf)

New Belt: 740 - 880 N (75 - 90 kgf, 165 - 198 lbf)

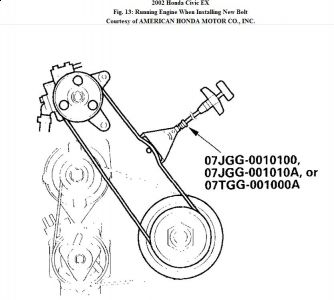

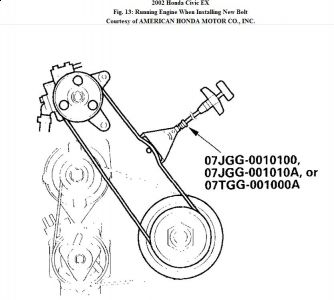

If you installed a new belt, run the engine for 5 minutes, then readjust the belt to the used

belt specification.

Adjustment

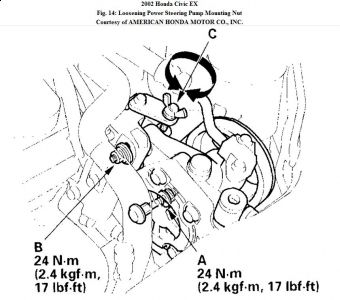

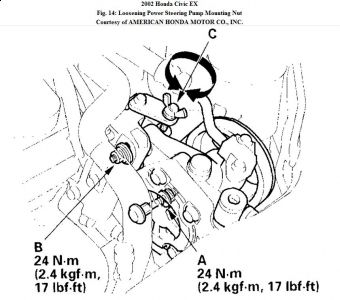

Loosen the power steering pump mounting nut (A) and pump locknut (B). 4 .

5 . Turn the adjusting bolt (C) to get the proper belt tension, then retighten the mounting nut and locknut.

6 . Start the engine and turn the steering wheel from lock-to-lock several times, then stop the engine and recheck the tension of the belt.

DEFLECTION METHOD

Inspection

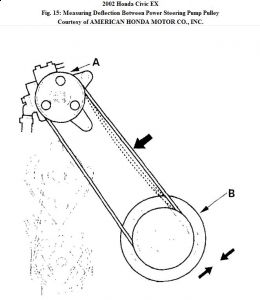

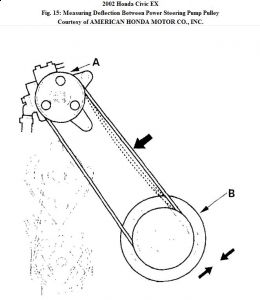

1 . Apply a force of 98 N (10 kgf, 22 lbf) and measure the deflection between the power

steering pump pulley (A) and the crankshaft pulley (B). If the belt is worn or damaged, replace it.

1 .

Deflection:

Used Belt: 13.0 - 16.5 mm (0.51 -0.65 in.

New Belt: 9.0 - 11.0 mm (0.35 -0.43 in.)

2 . If you installed a new belt, run the engine for 5 minutes, then readjust the belt to the used belt specification.

Adjustment

3 . Loosen the power steering pump mounting nut (A) and pump locknut (B).

4 . Turn the adjusting bolt (C) to get the proper belt tension, then retighten the mounting nut

and locknut.

5 . Start the engine and turn the steering wheel from lock-to-lock several times, then stop the

engine and recheck the tension of the belt.

SPONSORED LINKS

Thursday, October 22nd, 2009 AT 2:13 PM