Hi,

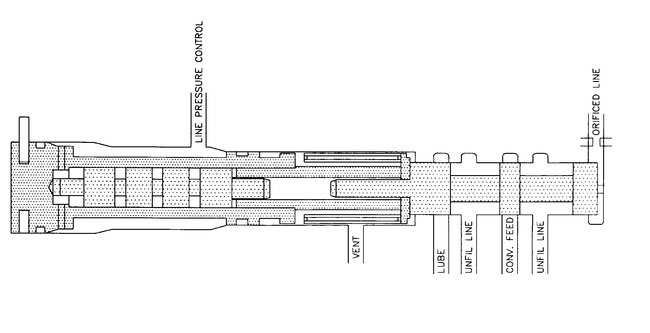

Have you checked for diagnostic trouble codes that are related to the transmission? I ask because it can be a few things. First, there could be a line pressure issue. Also, the fluid level could be low, but I assume you checked that after refilling when replacing the valve body. There is also a line pressure regulator. The pressure regulator valve controls line pressure to provide the correct pressure to apply clutches. If it is too high, you will get hard shifts. (Pic 1)

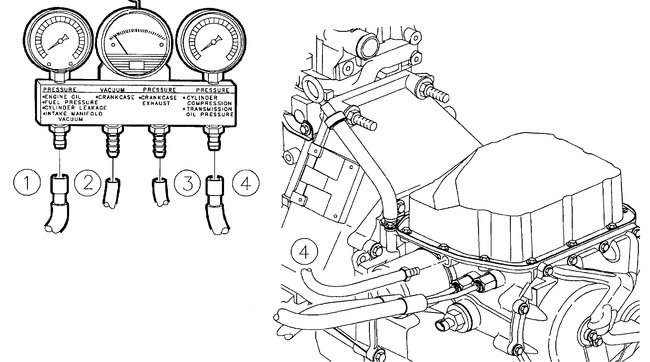

So, what I suggest is to check line pressure to see if it is within spec. Here are the directions for testing. Pics 2 and 3 correlate with the directions.

________________

2002 Saturn SC1 L4-1.9L SOHC VIN 8

Line Pressure Test

Vehicle Transmission and Drivetrain Automatic Transmission/Transaxle Testing and Inspection Component Tests and General Diagnostics Line Pressure Test

LINE PRESSURE TEST

LINE PRESSURE TEST

pic 1

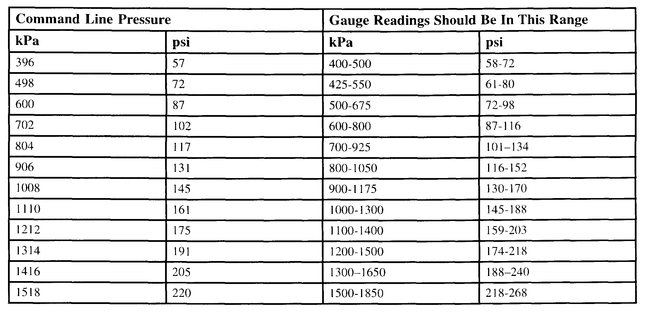

IMPORTANT: Be sure to perform both "Stepped Pressure Test" and "Maximum/Minimum Pressure Test" of the "Line Pressure Test."

STEPPED PRESSURE TEST

1. Run engine to bring transaxle to running temperature of 70°C (158°F).

2. Turn engine off.

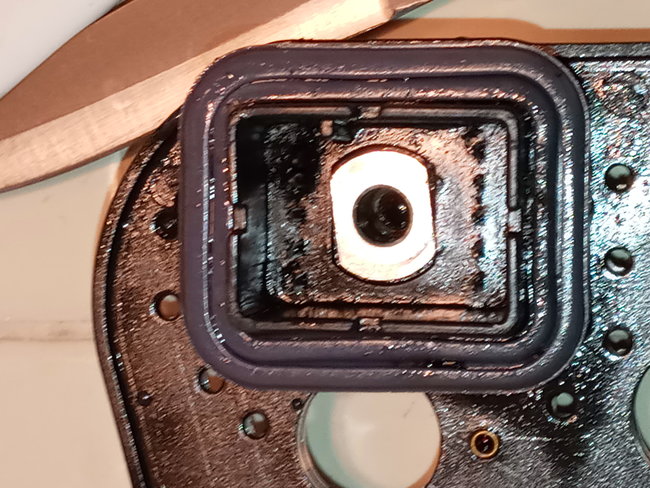

3. Remove transaxle fluid temperature sensor and install pressure gauge.

4. Reinstall temperature sensor in wire harness.

5. Connect the Scan tool.

6. Key On engine Off. On first menu selection, select "Special Functions."

7. Select Line Pressure.

8. Transaxle in Park.

9. Scan tool will prompt you to start engine.

10. Select Run and the test will begin. The test will set engine speed to 1500 rpm and command line pressure up in steps from 396 - 1518 kPa (57 - 220 psi) in 100 kPa (15 psi) intervals.

11. As test is in progress, watch the gauge to assure the gauge readings follow the commanded pressures. Use a dry erase marker to mark the face of the gauge because it will be difficult to record the readings in time.

Pic 2

MAXIMUM/MINIMUM PRESSURE TEST

1. Oil pressure maximum and minimum values at idle should be checked using the following procedure:

IMPORTANT: For proper reverse operation, it is important to have at least 1206 kPa (175 psi) of system pressure in reverse at 70°C (158°F).

- With gauge connected and bans at operating temperature.

- With engine idling in Park, line pressure should be 400 - 600 kPa (58 - 72 psi).

- Remove line pressure fuse (10 amp TRS LP) UHJB.

- With engine idling in P (Park), pressure should be 1206 - 1690 kPa (175 - 245 psi).

NOTE: High value may be slightly lower if transaxle temperature is greater than 110°C (230°F).

IMPORTANT: With engine in Park, and the 10 amp TRS LP line pressure fuse removed. Minimum pressure should be 1206 kPa (175 psi).

2. Remove pressure gage, install temperature sensor, use Saturn P/N 21485278 sealant with Tenons on threads (or equivalent). After the sensor has been connected, clear diagnostic trouble codes caused by having the sensor disconnected.

Torque:

Sensor - Transaxle Fluid Temperature Sensor-to-Case: 8 Nm (71 inch lbs.)

________________________

Let me know if this helps or if you have other questions.

Take care,

Joe

Images (Click to make bigger)

Wednesday, November 18th, 2020 AT 8:00 PM