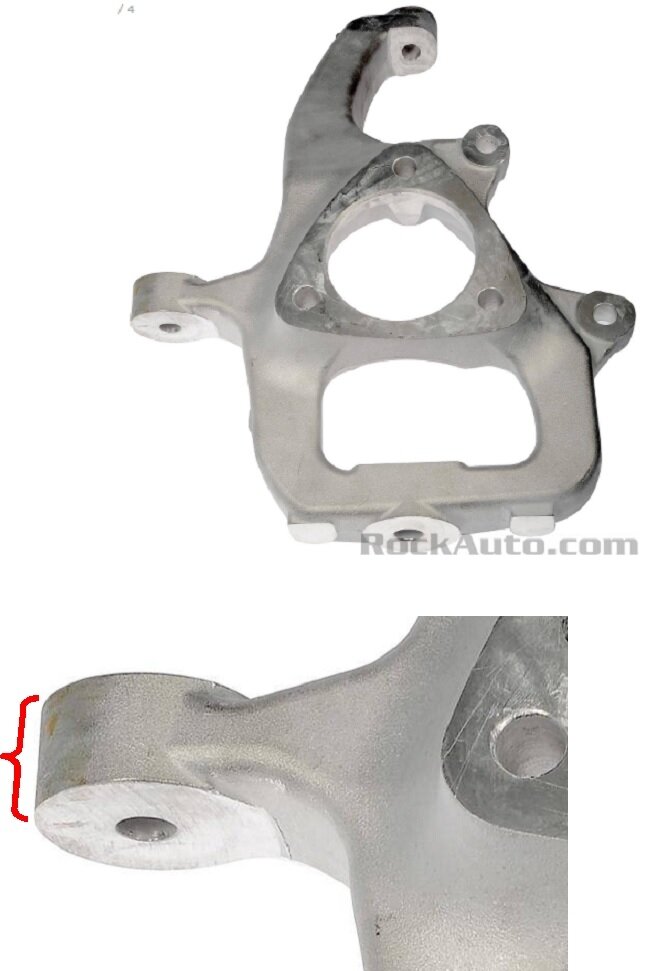

This is not a proper repair. The tapered stud on the new tie rod end will wedge tight on the narrow end of the hole, then it will feel tight, as you found, but if that hole is wobbled out, the same thing is going to happen and ruin the new tie rod end. Both parts have to be replaced at the same time when the stud has worked loose.

For the benefit of others researching this topic, let me add a note about the vibration you described. Much of that can apply to an inner CV joint on front-wheel-drive cars and on 4wd trucks. In ten years at the dealership, I ran into this about a dozen times, and all but one was on the right side, so if you're going to guess, start with the right half shaft. There's three large rollers on a tripod with lots of little needle bearings. Those rollers run back and forth in very highly polished slots. That allows the shaft to change length and angles as you turn and the vehicle goes up and down. Over time those slots develop a little wear. That causes the rollers to bind when they try to roll outside that normal area. Often this shows up on cars right after an engine mount that sets the sideways position of the engine is replaced. Those can be adjusted to move the engine / transmission up to perhaps as much as 1/4" one way or the other. That's way more than enough to change where those rollers run within the housing.

One of the clues to this is that this vibration goes away after about 35 to 40 mph because that's about when you're done hard accelerating out of a parking lot or side street. That higher torque makes it harder for the rollers to move outside of the worn area. Instead, being not able to let the joint change length or angle, as it rotates, the shaft pushes out on the wheel bearing / spindle / control arms, and rubber bushings. That pushes out on the knuckle, and the steering linkage is tied to that knuckle. That tugs the steering linkage back and forth once per wheel revolution.

The inner CV joint has to be disassembled to verify that wear, but this is where it gets confusing. Once the grease is wiped out of the housing, run your finger along those six highly polished rolling surfaces. If you feel the slightest irregularity, you really have a bad joint. In every one I identified, you need to shine a light in there and look at the reflections, similar to looking at the quality of bodywork on a restored classic car at a car show. We look at the grass as it reflects in the paint. When you see those tiny irregularities in the rolling surfaces, you've identified the cause of that vibration. It shows up in the steering wheel. The first time you run into this, you won't believe that could cause a problem.

To add to the misery, when half shafts are sent back for cores to be rebuilt, a lot of the people doing the work don't recognize that wear or even know what is considered "bad". They may reuse an old housing, then the next person gets that shaft with its vibration. Fortunately, new half shafts today are an extremely good value. I put a brand new one on my '88 Grand Caravan at around 400,000 miles for a different reason. It cost less than $70.00. Back in the '90s a rebuilt half shaft typically cost over $150.00. For such a low cost, there's no point in even replacing a torn boot.

Back to your truck. If the truck was not realigned after the last tie rod end was replaced, look at the position of the steering wheel. One shortcut I've used for my own vehicles is when I start out with a straight steering wheel, then just one tie rod end needs to be replaced, when it is adjusted correctly, the steering wheel will be straight again. The "toe" adjustment that is the final step in the alignment is done at the joints of the two inner and outer tie rod ends. Back in the '90s, to address a slight tire wear problem, we modified the factory specs for "total toe" from 1/8" toe-in to 1/16" toe in. Years ago a common spec for all brands of rear-wheel-drive cars and trucks was 1/8" toe-in plus or minus 1/8". At either extreme of the acceptable range, there would still be no noticeable tire wear. That's not the case today. That 1/16" change to total toe made a huge difference in tire wear patterns. That is getting real picky, but toe on one wheel can be off by almost 1/4" before you'll see it as an off-center steering wheel.

Our trucks have rack and pinion steering gears now, but since I'm no longer doing alignments, I don't know how picky they are for achieving good tire wear. The only thing you can do, assuming the steering wheel is straight, is to have the alignment rechecked, or simply keep an eye on the wear patterns on the front tires. We can see pulling to one side and off-center steering wheels right away. Tire wear takes time to show up. Look at the two edges of the tires' tread. If any one of the four edges is wearing faster than the rest of the tires, that one wheel could be tilted in or out on top too much. That's "camber". The adjustment affects tire wear on just that one tire, but it can be out of specs on each front tire. The clue is if you run your hand around the tire on those edges, they'll feel smooth.

Toe is a little trickier. That's the direction the wheels are steering when the steering wheel is straight. Most vehicles call for a little toe-in, meaning they're both steering toward the center of the vehicle. Road forces are expected to pull them back to make them perfectly parallel to each other when driving. Total toe is the sum of the readings on both wheels added together. That can be out of specs if just one wheel is out of adjustment or if both are. Even when just one is out of adjustment, it always affects tire wear equally on both tires. The clue to this is when you run your hands around the edges of the tread, you'll feel the blocks of rubber are not flat and smooth. Each block is like a little ramp. When running your hand one way, you might feel the high and low spots if they're bad enough, but the other way your fingers will catch on those high spots. That pattern will be on both tires. Often you can see it because road dust doesn't get worn off the low spots. The high spots will be scrubbed clean.

The point I'm not doing a good job of explaining is even if you keep tweaking the adjustment of a single new tie rod end until you get a straight steering wheel, it can still be off far enough to cause that tire wear pattern. If you see that pattern develop over the next 5,000 to 10,000 miles, you'll need to have the alignment rechecked. I never rotate my tires, but if you do, that wear may never have time to show up. When switched to the rear, any camber or toe wear will smooth out over time.

Now, to get back to that vibration, the first things that come to mind when you feel it in the accelerator pedal, is engine mounts and the exhaust system. Engine and transmission mounts have a metal bracket on the engine, another on the frame, then a piece of rubber sandwiched in between. If that rubber deteriorates, it can let one side of the engine drop a little until the two metal pieces contact each other. That will transmit normal engine vibration into the body where you will definitely feel it. The rear-view mirror will be vibrating at idle. This will be a much higher-speed vibration than that of an out-of-balance wheel.

Similarly, the exhaust system hangs on rubber spacers, inserts, or hangers, again, to isolate normal vibration from the cab. If any part is bent, mispositioned, or is binding to the point the two metal parts make contact, you'll feel that too. With a V-8 engine, the vibration will be four times faster than engine speed.

A more difficult source of vibration to find is from incorrect driveshaft angle, but this shows up more at higher speeds than what you described. This vibration is standard on older GM pickup trucks. It occurs on Ford conversion vans as little as six months old. For all other rear-wheel-drive vehicles, it's due to weak rear springs over time, not mileage. As they get weak, the rear sags a little. Normally driveshafts angle down from the transmission, or up as they leave the rear differential. Those angles force the bearing cups in the -joints to swivel as the shaft rotates. Swiveling back and forth prevents the needle bearings from staying in one place and pounding little depressions into those caps. It also reduces the tendency of the shaft to set up a harmonic vibration. (Think of the pendulum on a grandfather's clock and how it oscillates back and forth at its natural frequency). Driveshafts spinning at high speed want to set up that vibration too. That gets much worse as the three parts begin to form more of a straight line. We need the angle difference between the shaft, the stub shaft in the transmission, and the pinion gear in the differential, to dampen that vibration. The Ford vans had this vibration due to the increased weight of the conversion stuff. As the rear sags, the driveshaft angle decreases more and more, making the natural tendency to vibrate more noticeable. New, stronger rear springs solved that. You can get that same annoying vibration from tight universal joints. In one late '80s Ford van, a single tight joint made it almost impossible to get up to 55 mph. It felt like we were dragging an anchor. It zipped right along just fine once that joint was replaced.

I purposely avoided getting into a discussion about wheels and tires because you're describing a much higher frequency sensation. If you think this still might be tire or wheel-related, I'll describe using a dial indicator to find what can look like a bent wheel. You'll feel that in the steering wheel, and if bad enough, in the brake pedal, but that would show up as one bounce per wheel revolution.

Let me know if you think I'm on the right track, or if you can add any other clues, hints, or observations.

Monday, May 1st, 2023 AT 9:30 PM