Check you are getting power to both pumps ?

FUEL DELIVERY

System Types

Electric fuel delivery systems differ in design depending on model. System designs use one of the following configurations:

Single tank with one Fuel Delivery Assembly (FDA). See Fig. 1 .

Dual tank with one FDA per tank.

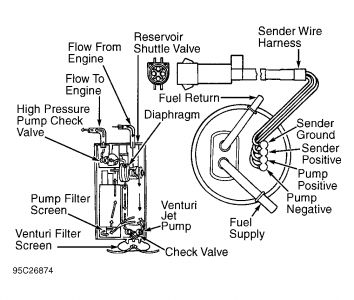

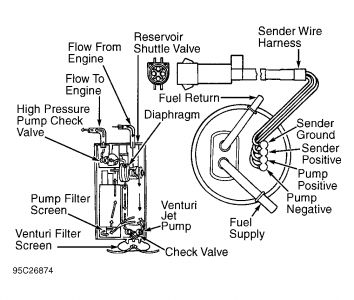

Fig. 1: Identifying Fuel Delivery Assembly (FDA)

Courtesy of FORD MOTOR CO.

Fuel Delivery Assembly (FDA)

The FDA consists of a fuel pump inside a reservoir that is attached to the pump and sender assembly. See Fig. 1 . In a 2-tank system, there is one FDA per tank. Fuel sender assembly handles the fuel switching through internal valves.

Fuel reservoir is used to prevent fuel flow interruptions during extreme vehicle maneuvers when fuel tank level is low. Reservoir is located in-tank and is either molded or welded into fuel tank or is part of FDA.

Shuttle valve opens fuel return line to fuel tank when fuel pressure on shuttle diaphragm exceeds opposing check valve spring force. When pump is de-energized, supply check valve closes to maintain pump prime and fuel supply line pressure.

A portion of high pressure flow from the pump is diverted to operate the venturi jet pump. The jet pump draws fuel from the tank into the FDA. This ensures adequate fuel supply during extreme vehicle maneuvers and steep vehicle attitudes when fuel level is low. If FDA is defective, it must be replaced as an assembly.

Monday, July 8th, 2019 AT 12:36 PM

(Merged)